Dust collection equipment, robot system, discharge device and discharge method

A technology of robot system and dust collection equipment, which is applied in the field of electric power, can solve the problems of low discharge efficiency and difficulty in selecting the parameters of discharge electronic components, etc., and achieve the effect of high discharge efficiency, easy realization, and large load power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

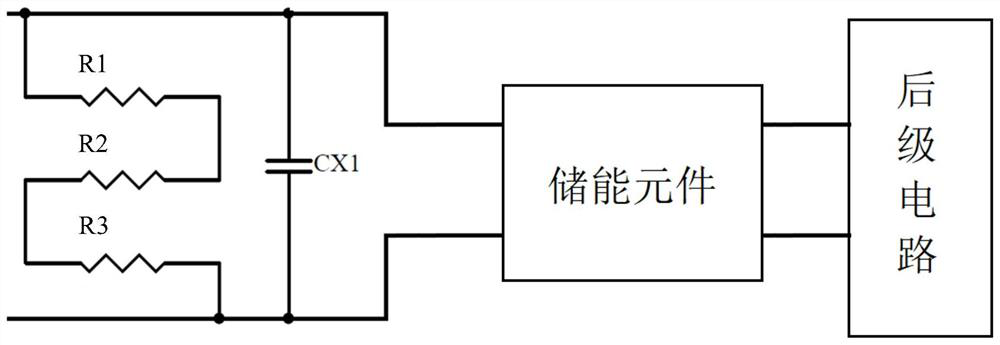

[0041] An implementation solution in the prior art is to use such as figure 1 The resistors R1, R2, and R3 shown in the figure release the remaining electrical energy on the plug; this method needs to adjust the capacitance of the capacitor CX1 and the resistance of the resistors R1, R2, and R3 within the time required by the safety regulations. , release the residual power of the power plug to below a safe voltage (such as 42.4V). Among them, CX1 is connected with the energy storage element, and the energy storage element is used to connect the subsequent circuit. R1, R2, R3 and CX1 can be understood as a discharge circuit. When the user pulls out the plug, R1, R2, R3 and CX1 discharge the remaining electric energy of the power plug. However, if the resistance value is too large, the time required for discharge will be too long, which cannot meet the time required by safety regulations; but if the resistance values of R1, R2, and R3 are too small, the time required for dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com