Method for analyzing torsional vibration of shafting of vehicle range extender

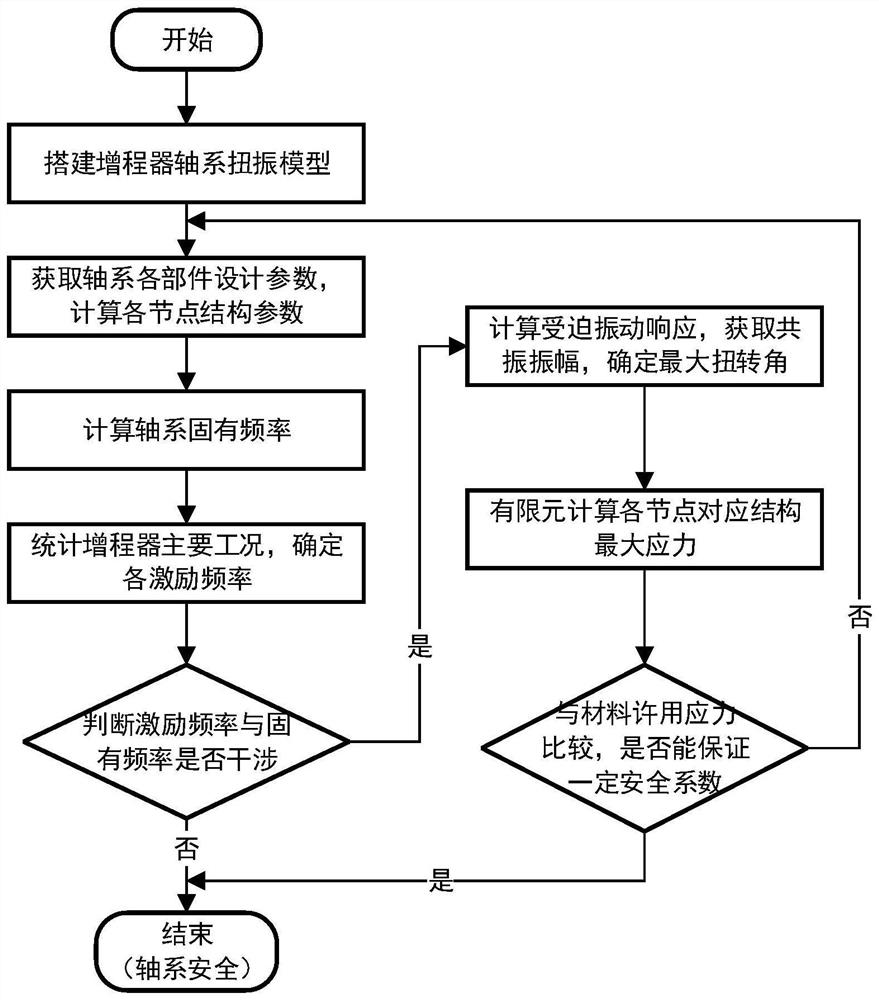

A technology of torsional vibration and analysis method, applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., can solve the problems of insufficient comprehensiveness and excessive calculation, and achieve the effect of reducing the risk of vibration failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0064] Taking a vehicle range extender as an example, the technical solution is described in detail.

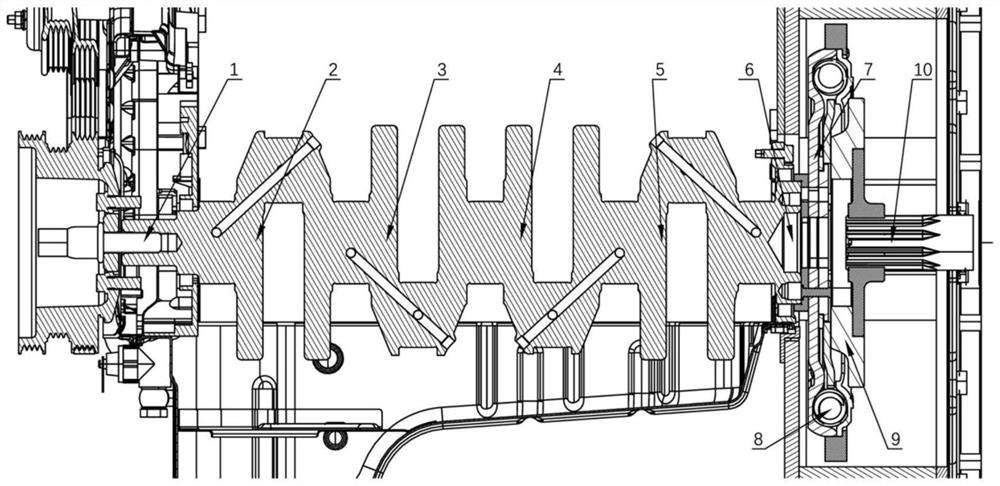

[0065] The shaft system structure of the range extender is as follows: figure 2 As shown, the output end of the crankshaft is connected to the input flange of the torsional vibration damper through fasteners, and the output end of the torsional vibration damper is connected to the motor shaft through a keypad. The torsional shock absorber consists of two flywheel discs connected in the middle by a damping spring and a damping element.

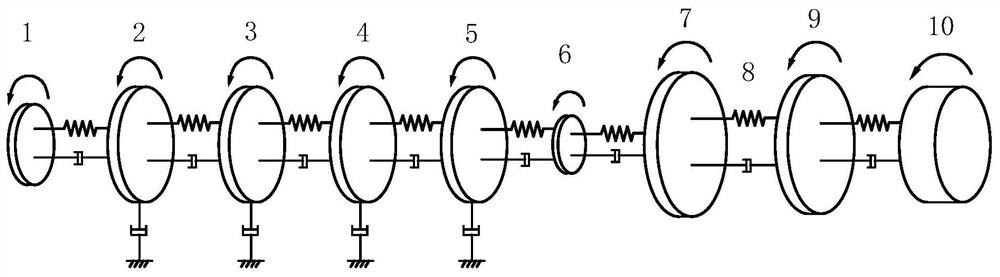

[0066] First of all, the shaft system of the range extender is simplified in sections, in which the engine crankshaft is divided in the middle of each main journal, and divided into the front end of the crankshaft, the corresponding crank throw of each cylinder and the output end; the torsional shock absorber is divided into front and rear according to the shock absorber The input end and the output end, the vibration damping spring and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com