Chemical source introducing system of atomic layer deposition coating equipment

A technology of atomic layer deposition and coating equipment, which is applied in the direction of gaseous chemical plating, coating, metal material coating process, etc., can solve the problems of few types of chemical source gas introduction, the quality of film-forming film products, and the decline, so as to avoid Product quality problems, guaranteed film-forming effect, shortened time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

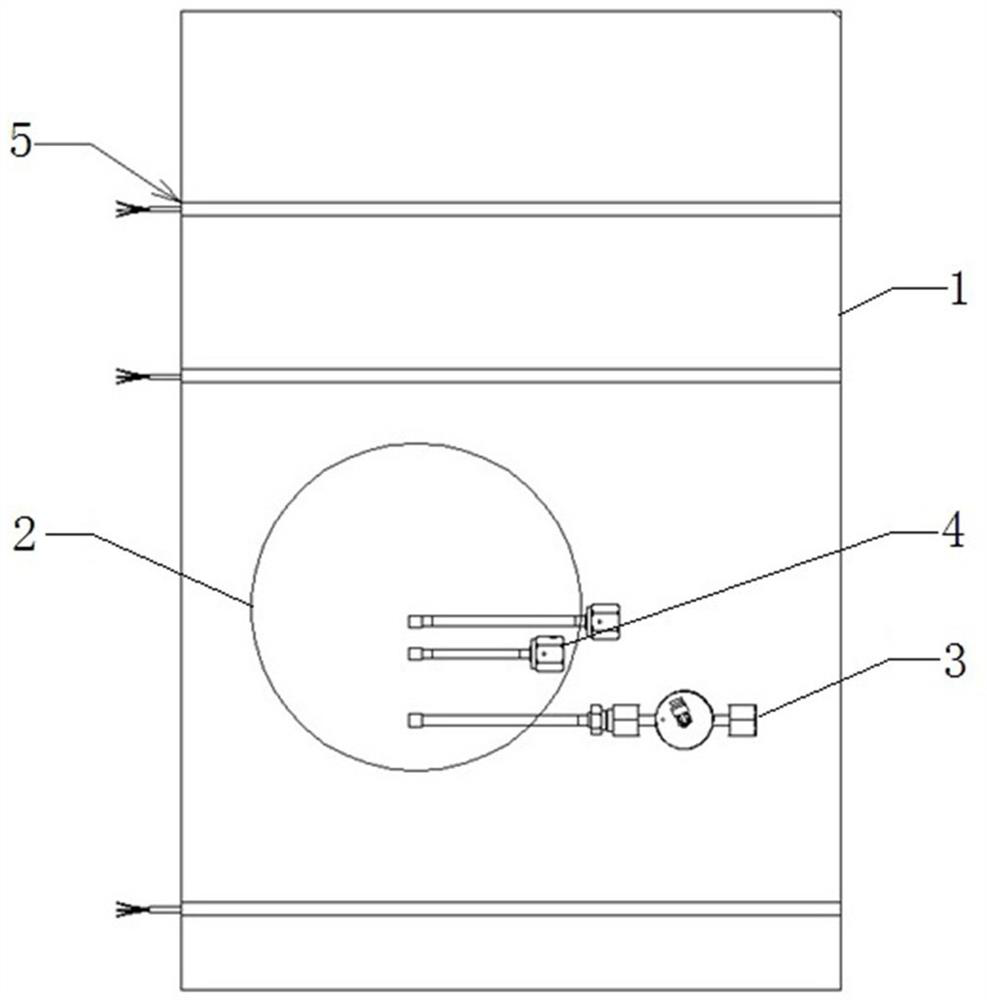

[0022] Embodiment: In this embodiment, the chemical source introduction system of the atomic layer deposition coating equipment is used to introduce the chemical gas in the atomic layer deposition coating process into the film forming chamber, so as to form films on the products loaded in the film forming chamber.

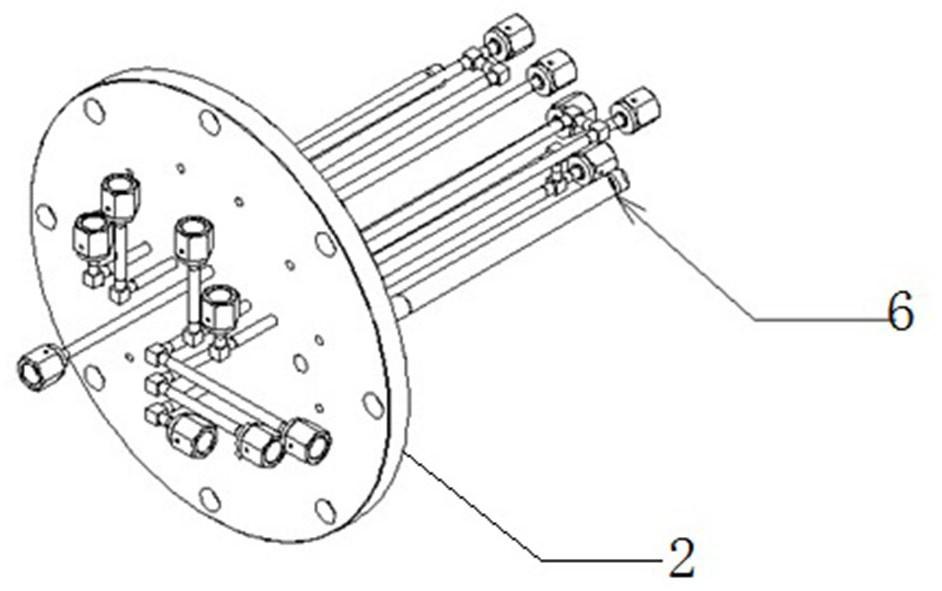

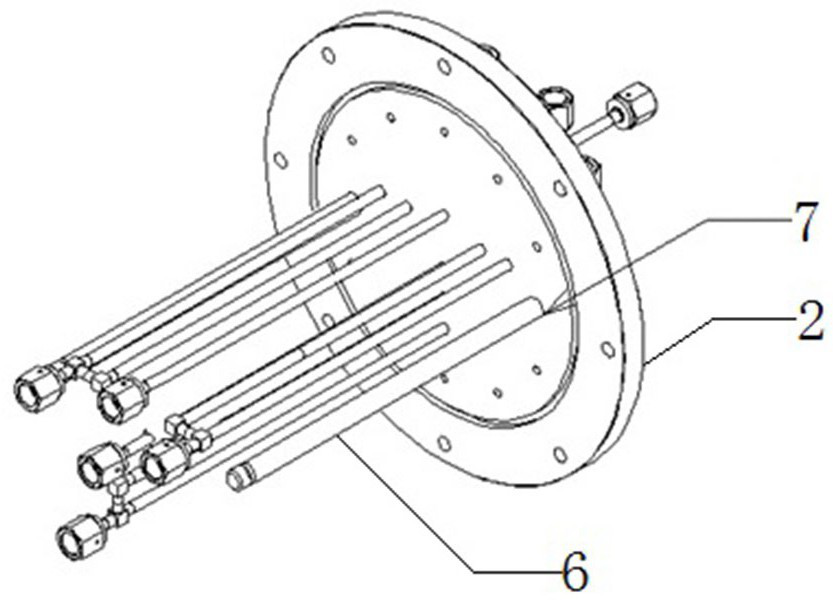

[0023] Such as figure 1 As shown, the main body of the chemical source introduction system in this embodiment includes a valve seat bottom plate 1 , a gas introduction flange 2 , and a chemical source introduction pipeline 3 . Among them, the chemical source introduction pipeline 3 corresponding to the quantity of the chemical gas required for the atomic layer deposition film forming process can be provided on the valve seat bottom plate 1, and several chemical source introduction pipelines 3 can be installed on the gas inlet flange 2. On the bottom plate 1 of the valve seat. One end of the chemical source introduction pipeline 3 is arranged on the atmospheric sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com