Placement rack for PCB production

A technology for PCB boards and racks, applied in external frames, containers to prevent mechanical damage, packaging of vulnerable items, etc., can solve the problems of PCB board production impact, PCB board surface wear, etc., to reduce the contact area and increase Friction, storage-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

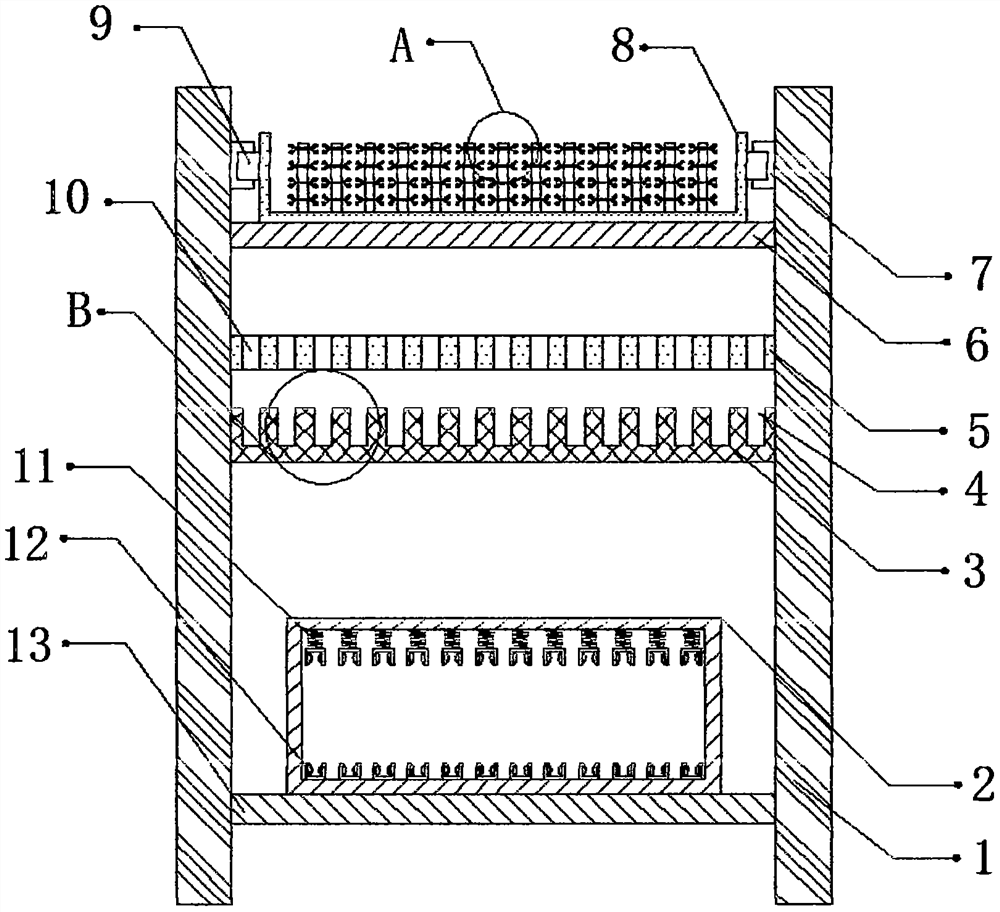

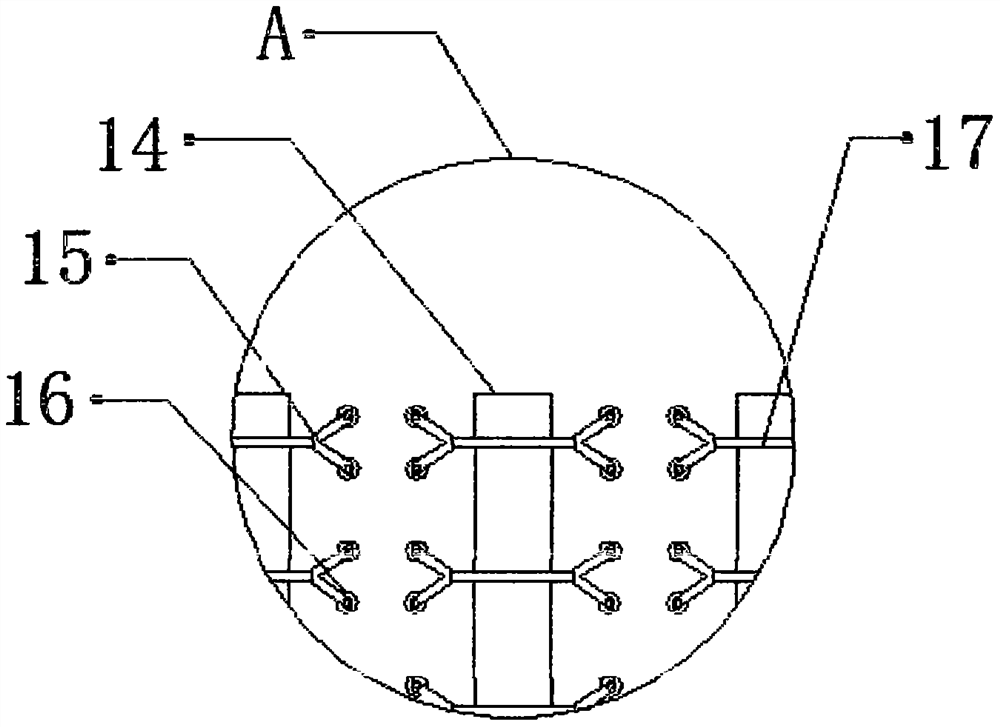

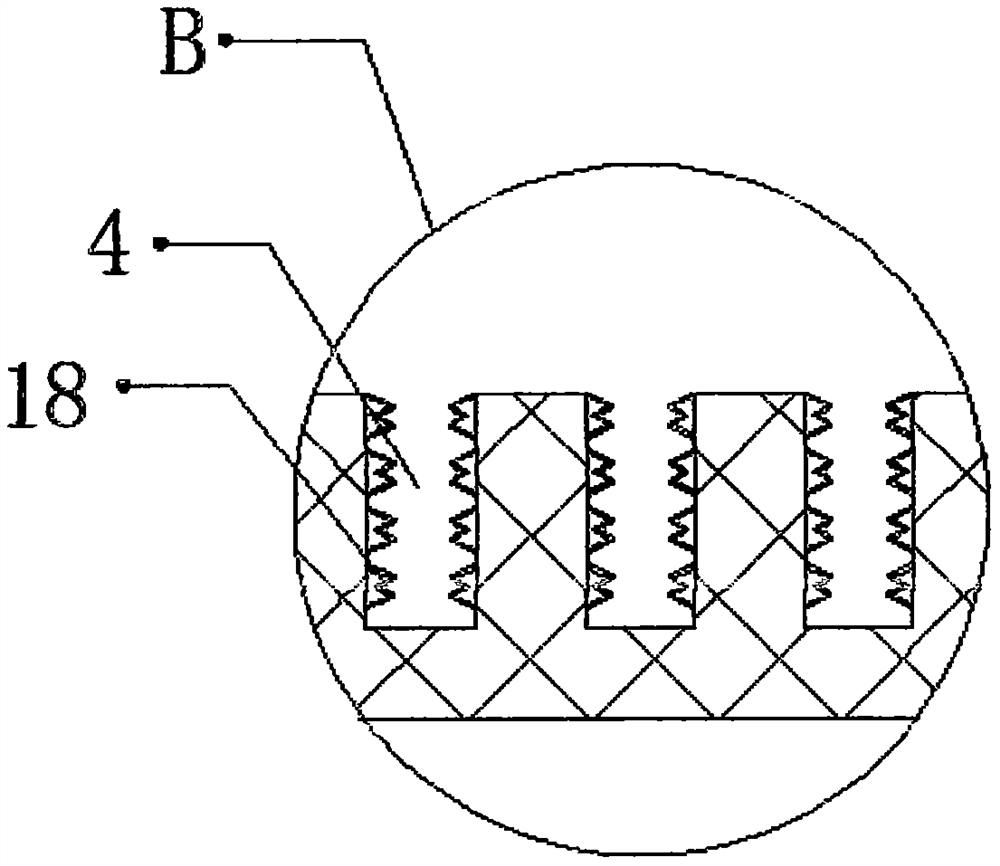

[0030] refer to Figure 1-4 , a placement rack for PCB board production, including two fixed plates 1, a fixed block 6 is connected by bolts near the top between the outer walls of the opposite side of the two fixed plates 1, and the top outer wall of the fixed block 6 is slidably connected There is a support frame 8, and the outer walls on the opposite side of the two fixed plates 1 are connected with channel steel slide rails 7 by bolts, and the inner walls on the opposite side of the two channel steel slide rails 7 are slidably connected with sliders 9. The opposite side outer walls of the block 9 are connected with the support frame 8 by bolts, and the bottom inner wall of the support frame 8 is connected with a plurality of partitions 14 by bolts, and one side outer wall of the partition 14 is provided with a plurality of through holes. The inner wall of the through hole is slidably connected with a slide bar 17, and the outer walls on both sides of the slide bar 17 are c...

Embodiment 2

[0039] refer to Figure 5 , a placement rack for PCB board production. Compared with Embodiment 1, in this embodiment, a storage plate 20 is connected by bolts between the outer walls on the opposite side of the two fixed plates 1, and the shape of the storage plate 20 is wavy. The outer wall of the top of the storage board 20 is connected with a plurality of bumps 19 by bolts, and the bumps 19 are distributed in a stepped shape. The shape of the bumps 19 is stepped, which can reduce the size of the PCB board and the storage board while storing the PCB board. The contact area between 20 is convenient for storing the PCB board.

[0040]Working principle: When in use, store the produced PCB board on the shelf, and the friction force between the clamp block 15 and the PCB board can be reduced by the ball 16, so as to facilitate the storage of the PCB board and prevent the PCB board from being damaged due to friction. The surface of the board is worn, and the shape of the clamp b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com