Mobile testing mechanism for colorimeter

A technology of mobile testing and colorimeter, applied in sorting and other directions, can solve problems such as eye damage, high misjudgment rate, and low efficiency, and achieve the effect of reducing eye damage and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

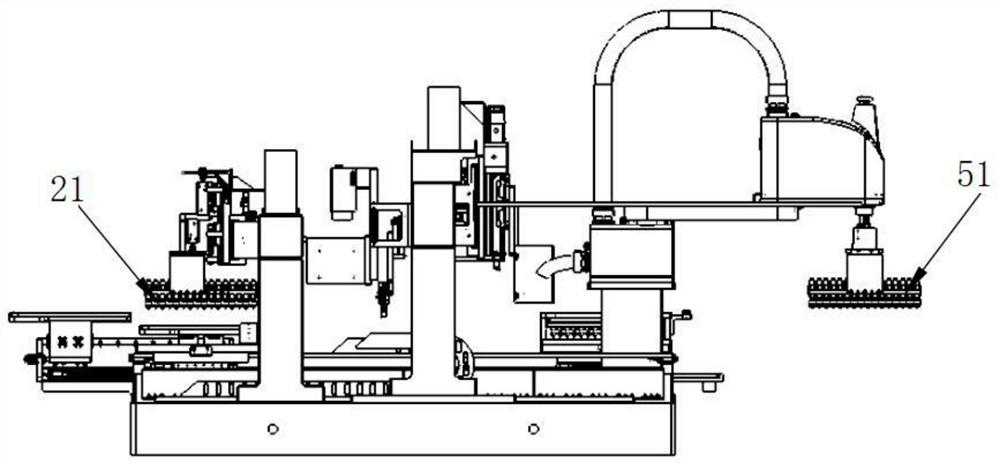

[0028] see Figure 1 to Figure 3 , as shown in the legend, a colorimeter mobile testing mechanism, including:

[0029] A conveying unit, which includes a carrier 11 for carrying products and a moving device A12 that drives the carrier 11 to move along the first horizontal direction and sequentially passes through the loading station, visual positioning station, color detection station and unloading station;

[0030] Loading unit, which includes a group of products in the material tray 101 at the unloading station that is grasped at one time and placed on the loading platform at the loading station and the loading gripper 21 that drives the material Movement device B that moves between the unloading area and the loading station;

[0031] A visual positioning unit, which includes a visual positioning device 31 that is located above the visual positioning station and calculates the actual position of the product after taking pictures and taking images, and drives the visual posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com