Open-pit mine water gushing direction identification and treatment method

A technology for direction identification and open-pit mining, which is applied in open-pit mining, earthwork drilling, special mining, etc., can solve the problems of large number of grouting holes, large hole depth, high investment and operating costs, and achieve the purpose of making up for ambiguity, Strengthen the monitoring of water volume and prevent deformation caused by thermal expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

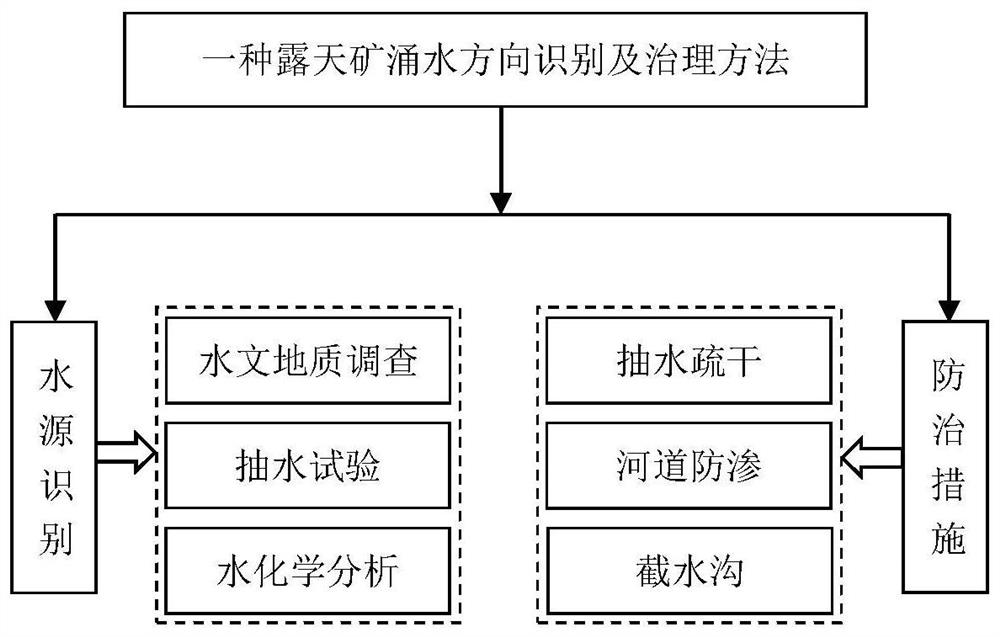

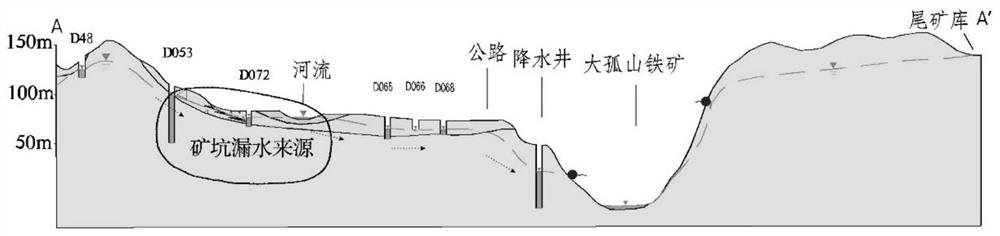

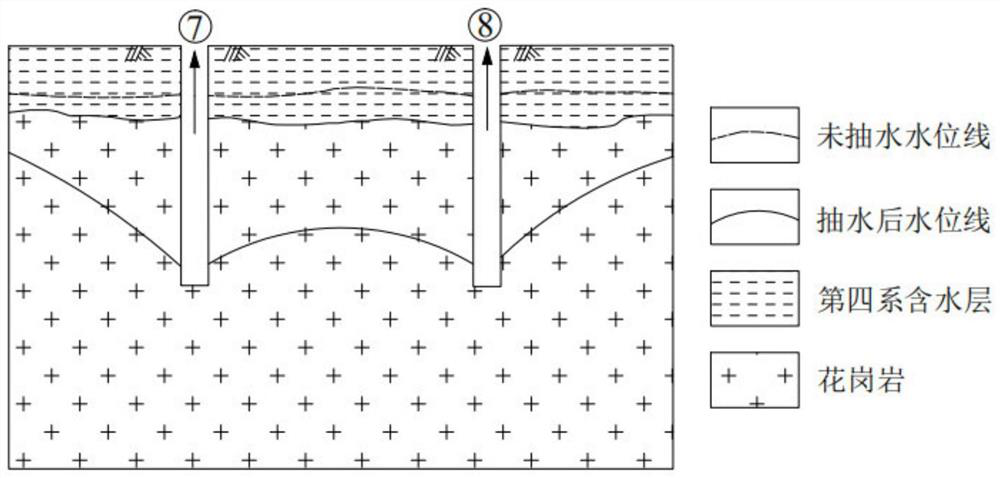

[0037] Such as Figure 1-Figure 6 As shown, a method for identifying and controlling water gushing direction in an open-pit mine of the present invention comprises the following steps:

[0038] Step 1. Conduct hydrogeological survey

[0039] Using the digital elevation model (DEM) provided by the Geographic Data Cloud of the Chinese Academy of Sciences, the ArcGIS hydrological analysis module is used to extract the information of the river network, sub-basin boundaries, watersheds and related watershed geomorphology in the study area, determine the hydrogeological survey area, and initially describe the groundwater in the study area and the runoff process of surface water to clarify the hydrogeological characteristics of the mining area.

[0040] Step 2. Sampling and cluster analysis based on hydrochemical characteristics

[0041] Collect water sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com