Ribbon loom

A ribbon loom and load-carrying mechanism technology, applied to looms, small looms, textiles, etc., can solve the problems of lowering the quality of ribbons, the limitation of weaving silk threads, and the collision and winding of silk threads, so as to reduce processing accidents and reduce the probability of occurrence , to avoid the effect of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

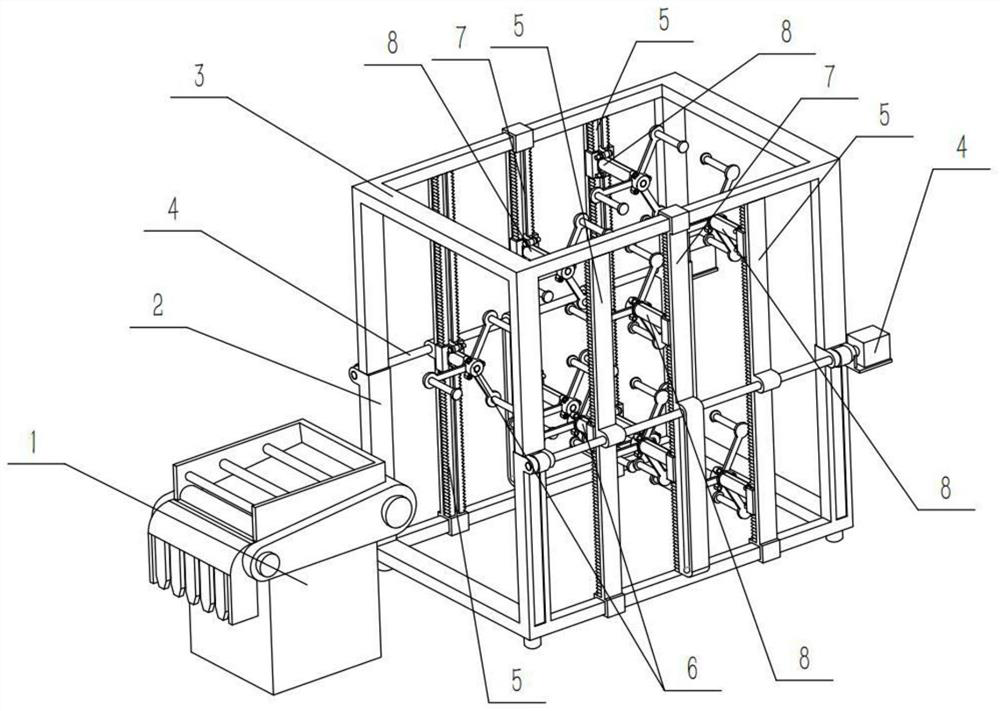

[0035] Combine below Figure 1-14 To illustrate this embodiment, a ribbon loom includes a ribbon loom 1, and the ribbon loom also includes a support base 2, a lifting frame 3, a drive mechanism 4, a column mechanism I5, a bearing mechanism I6, a column mechanism II7, and a bearing mechanism II8. The supporting base 2 is arranged on the rear side of the loom 1, the lifting frame 3 is slidably connected to the upper end of the supporting base 2, the supporting base 2 and the lifting frame 3 form a rear frame, and the driving mechanism 4 is provided with two Two driving mechanisms 4 are respectively arranged on the left and right sides of the upper end of the support base 2, and the two driving mechanisms 4 are all connected with the lifting frame 3. There are four column mechanisms I5, and the four column mechanisms I5 are two The two are relatively fixedly connected to the left and right sides of the support base 2, and two column mechanisms II7 are provided, and the two column...

specific Embodiment approach 2

[0038] Combine below Figure 1-14 This embodiment will be described. This embodiment will further describe the first embodiment. The support base 2 includes a base 2-1 and a sliding tube 2-2. There are four sliding tubes 2-2. The four sliding tubes 2- 2 are respectively fixedly connected to the four corners of the upper end of the base 2-1, the two driving mechanisms 4 are respectively arranged on the outer sides of the upper ends of the four sliding tubes 2-2, and the lower ends of the lifting frame 3 are slidably connected to the four sliding tubes. In 2-2, the four column mechanisms I5 are fixedly connected to the left and right sides of the base 2-1 in pairs.

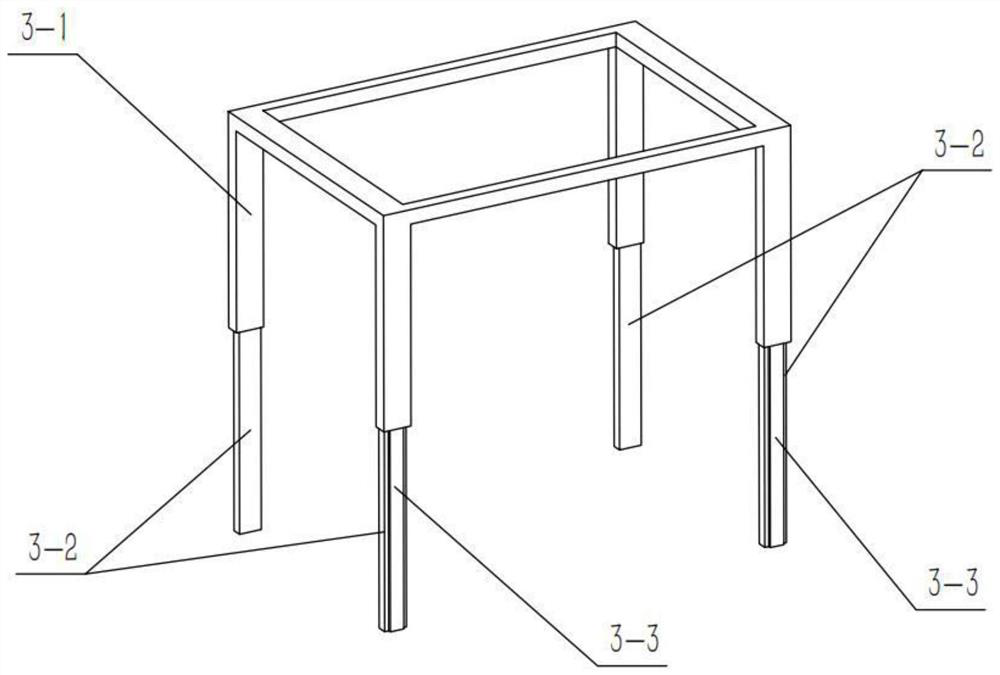

specific Embodiment approach 3

[0040] Combine below Figure 1-14 This embodiment will be described. This embodiment will further illustrate the second embodiment. The lifting frame 3 includes a bracket 3-1, a sliding rod 3-2 and a rack 3-3. The sliding rod 3-2 is provided with four One, four sliding rods 3-2 are fixedly connected to the four corners of the lower end of the bracket 3-1 respectively, and the racks 3-3 are provided with four, and the four racks 3-3 are respectively fixedly connected to the four sliding rods 3 -2 outside, the four sliding rods 3-2 are respectively slidingly connected in the four sliding tubes 2-2, and the two column mechanisms II7 are respectively fixedly connected to the left and right ends of the middle part of the bracket 3-1, and the two said The driving mechanism 4 is respectively connected with the transmission of the four racks 3-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com