Mounting tool for front-engine front-wheel drive (FF) engine and suspension frame

A technology for installing tooling and engines, applied in manufacturing tools, hand-held tools, etc., can solve the problems of worn screw grooves, deformation of raised parts, affecting the efficiency of engine assembly, and achieve the effect of easily locking screws and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

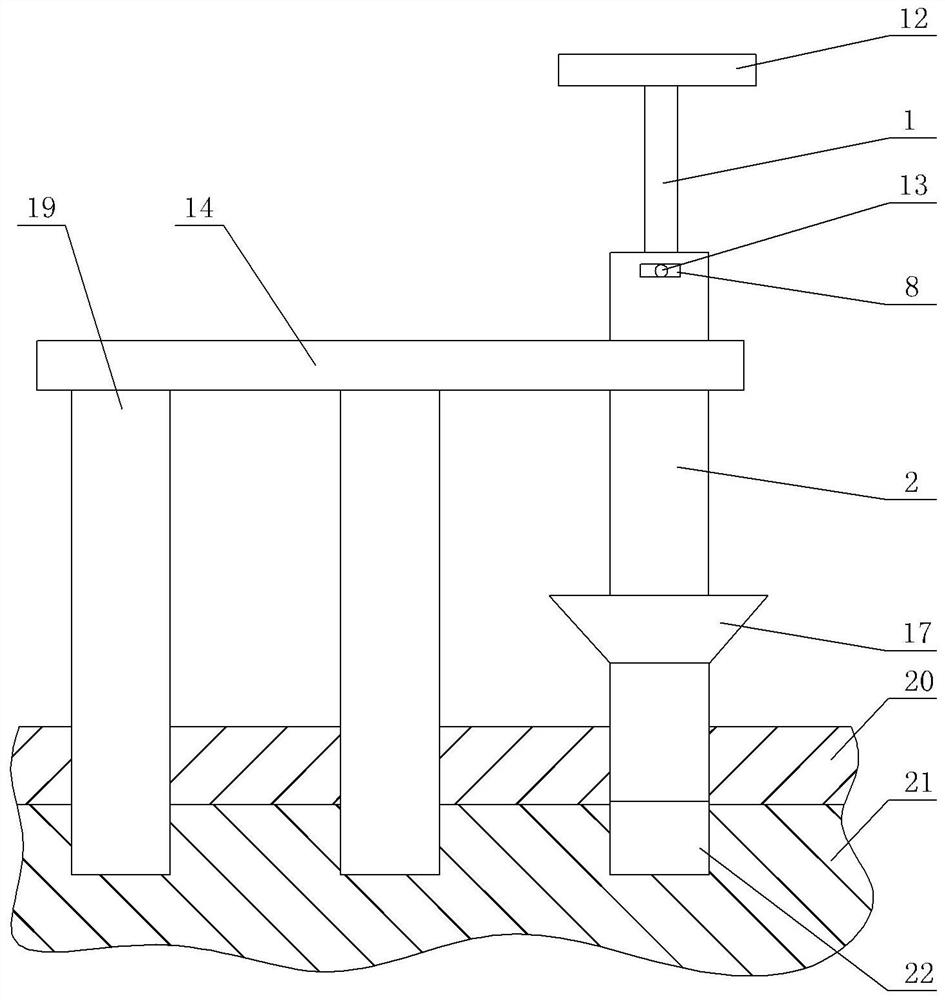

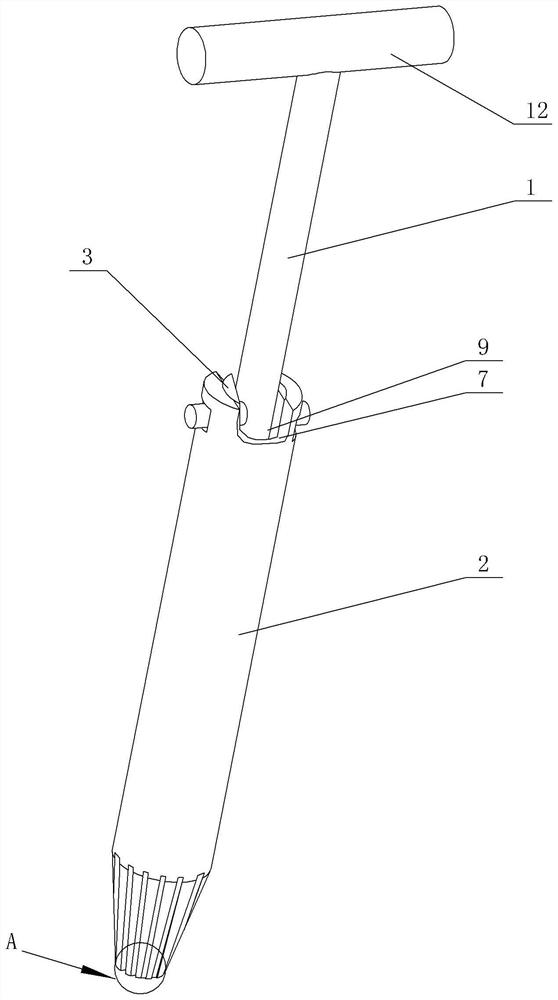

[0028] Embodiment one is basically as attached Figure 1-6 Shown: as figure 1 The shown front front drive engine 21 and suspension frame 20 installation tooling include positioning plate 14, grip bar 1, twist pipe 2 and as figure 2 , 4 As shown in the screw rod 3, two positioning rods 19 are welded on the positioning plate 14, holes are opened on the positioning plate 14, the screwing tube 2 is slidingly connected with the side wall of the hole, and the screwing tube 2 and the two positioning rods 19 on the same vertical plane.

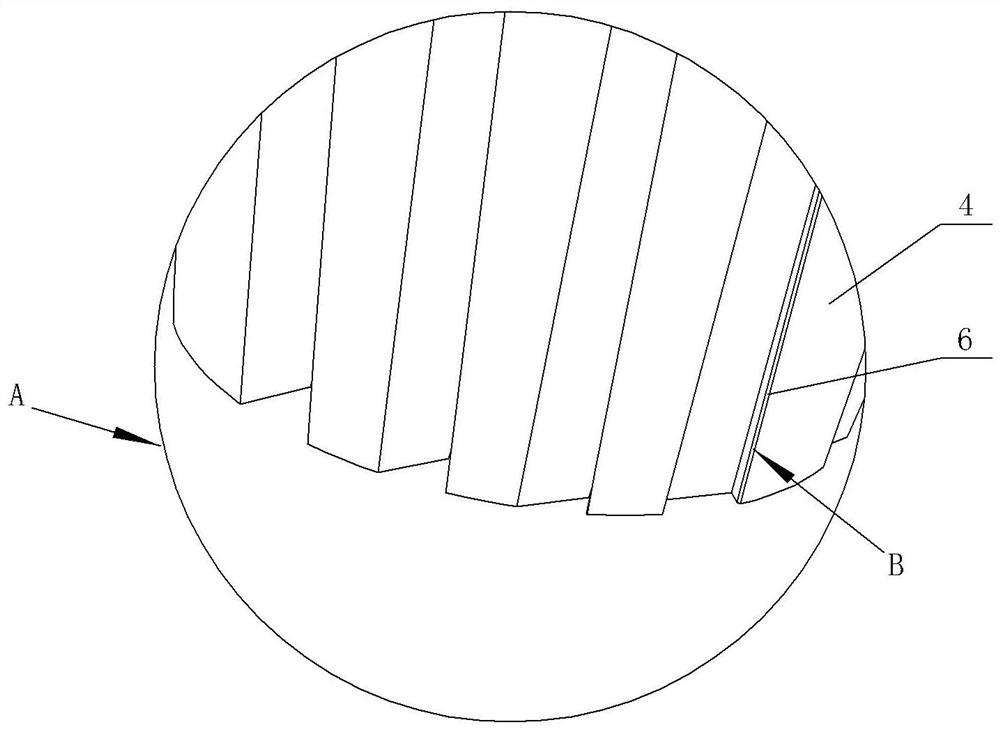

[0029] like figure 2 As shown, the lower end of the screw tube 2 is tapered; image 3 As shown, the lower end of the screw tube 2 is distributed with screw teeth 4 along the circumferential direction, such as Figure 4 As shown, there is a cavity 5 in the screw tooth 4, such as image 3 As shown, there is an opening 6 at the transition position (position B shown) between the tooth surface of the screwing tooth 4 and the end surface of the scre...

Embodiment 2

[0035] On the basis of Example 1, as Figure 4 As shown, the external rotation of the screw tube 2 is provided with an outer sleeve 15, and the lower end of the outer sleeve 15 is fixed with a magnet 16, and the magnet 16 arranged at the lower end of the outer sleeve 15 is adsorbed with the suspension frame 20, so that the screwing can be improved. Tube 2 Stability. The diameter of the screw rod 3 is greater than the diameter of the upper end of the card body 10, and the upper end of the clamp tooth 11 is welded to the lower end surface of the screw rod 3, which is conducive to improving the firmness of the clamp tooth 11; the clamp tooth 11 is made of cast iron, which can ensure The strength of the locking tooth 11 is large enough. In addition, the connecting rod 13 is coated with a graphite powder layer, which can ensure that the connecting rod 13 slides smoothly in the chute 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com