A kind of high-rise outer frame structure and construction method thereof

An outer frame, high-rise technology, applied in the direction of house structure support, house structure support, building structure, etc., can solve the problems of affecting the safety of workers, damage, large hook force, etc., to achieve convenient installation and disassembly, and more stable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

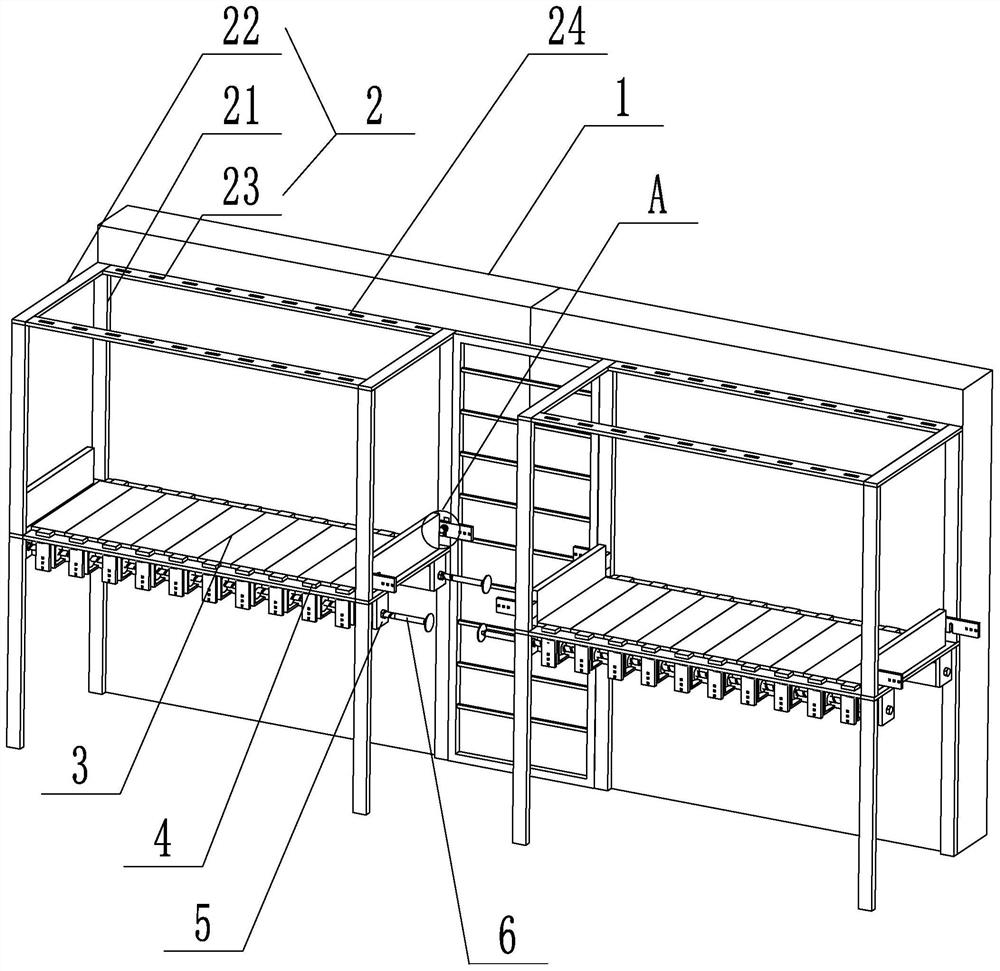

[0041] refer to figure 1 , is a high-rise outer frame structure disclosed by the present invention, including prefabricated blocks 11 prefabricated on the wall 1 and frame 2 connected with the prefabricated block 11, frame 2 includes vertical boards 21, transverse boards 23 and longitudinal boards 22.

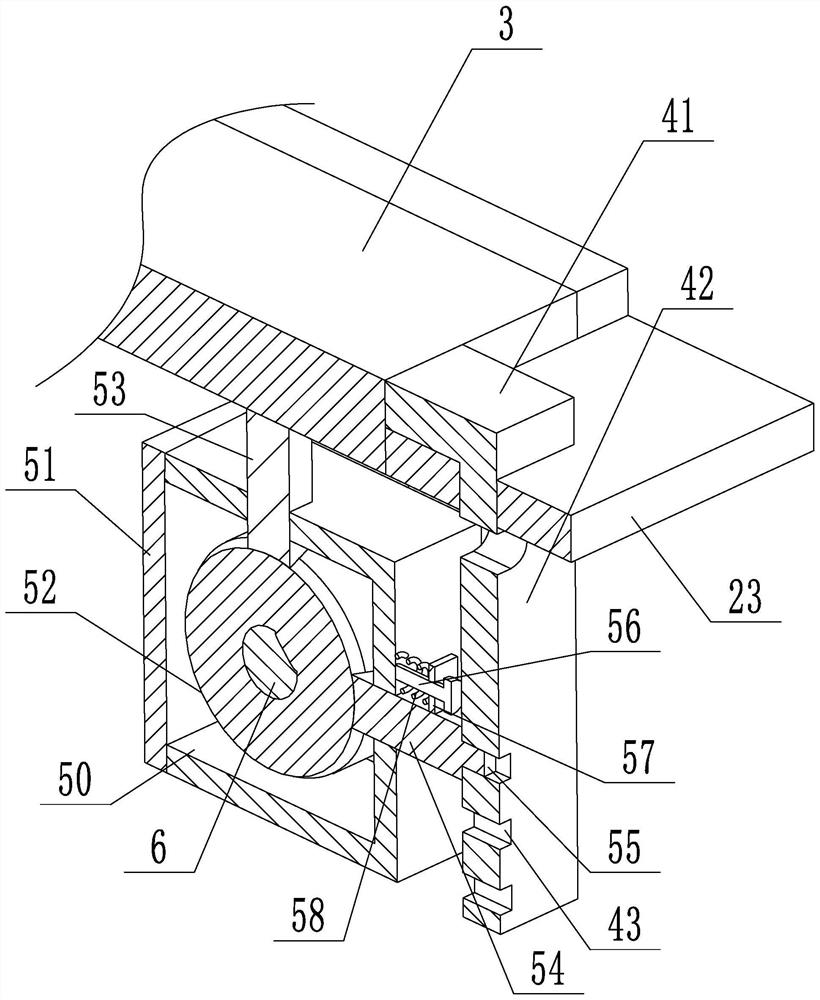

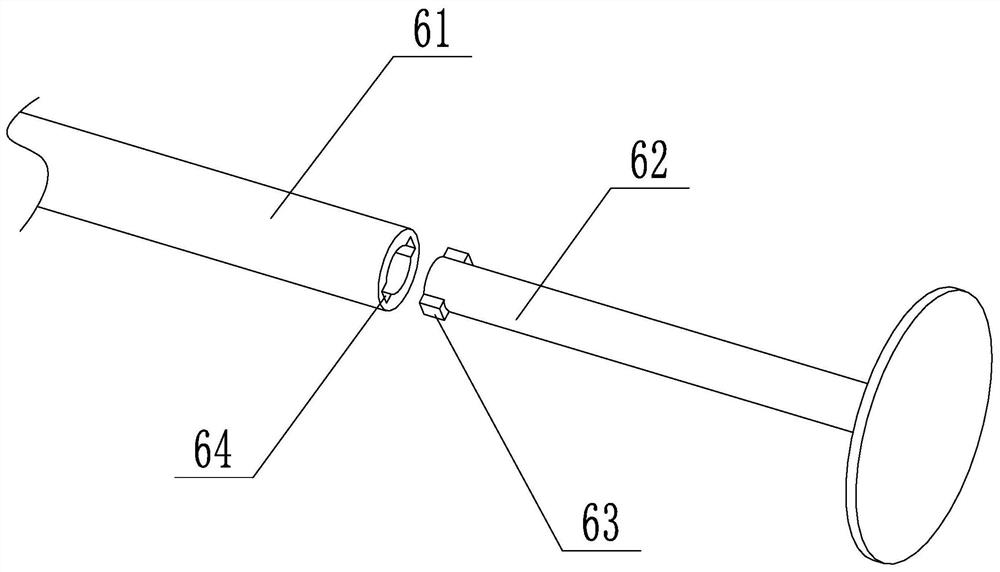

[0042] refer to figure 1 , figure 2 A plurality of support plates 3 are installed between the transverse plates 23, the support plates 3 are arranged along the length direction of the transverse plates 23, L-shaped clamping plates 4 are formed on the bottoms of the two ends of the support plates 3, and the clamping plates 4 The width is less than supporting plate 3. The transverse plate 23 is provided with a transverse groove 24 along its length direction to cooperate with the clamping plate 4. The clamping plate 4 includes a transverse portion 41 and a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com