Rail train bogie fatigue life estimation method

A fatigue life and rail train technology, applied in the mechanical field, can solve the problems of inability to truly monitor stress concentration points, inability to accurately monitor the stress condition of the framework, increase data acquisition and maintenance costs, etc., so as to avoid installation acquisition costs and maintenance costs. , to avoid the large gap between actual working conditions and the effect of accurate fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

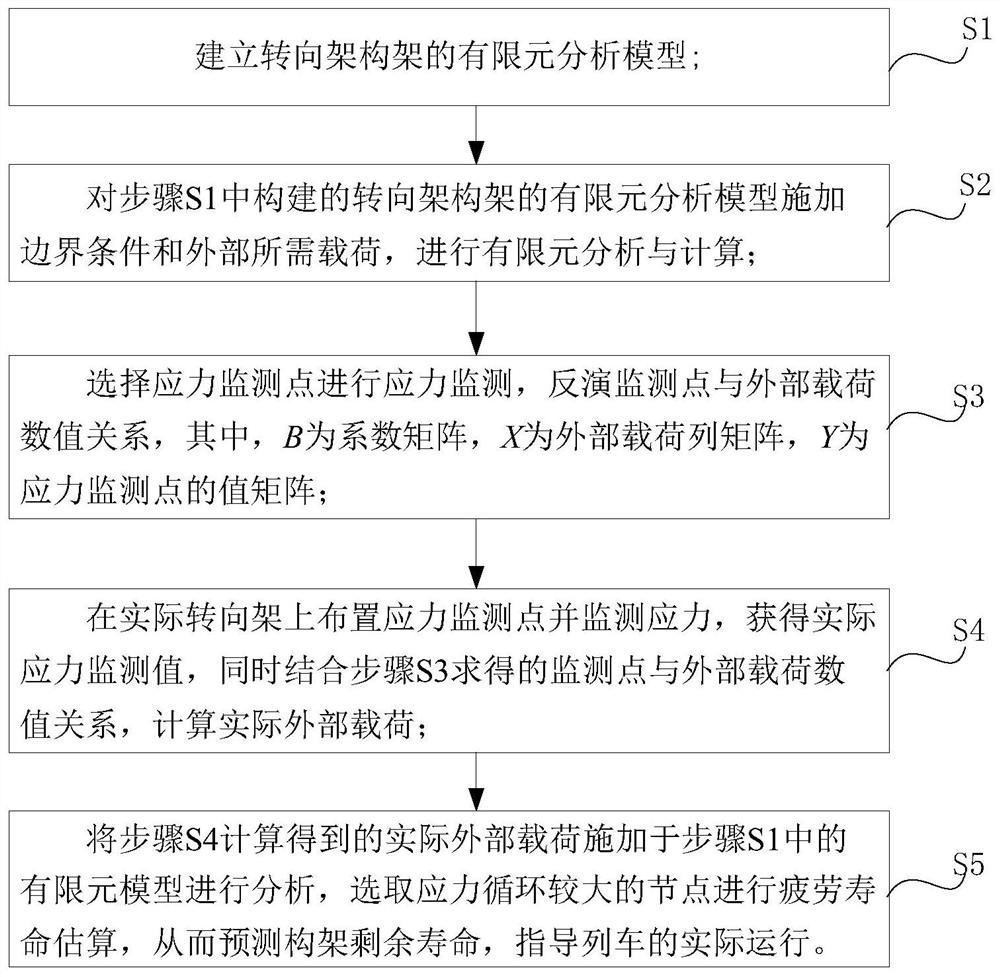

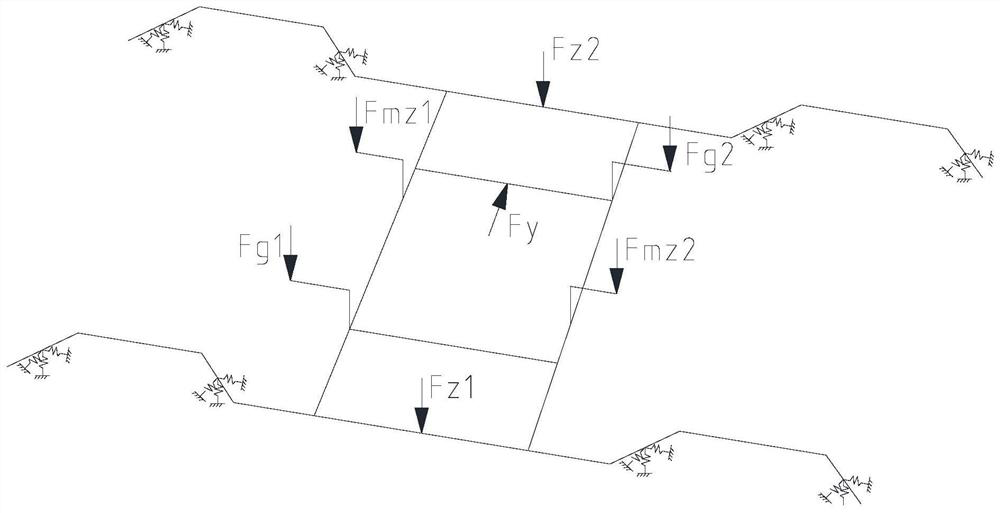

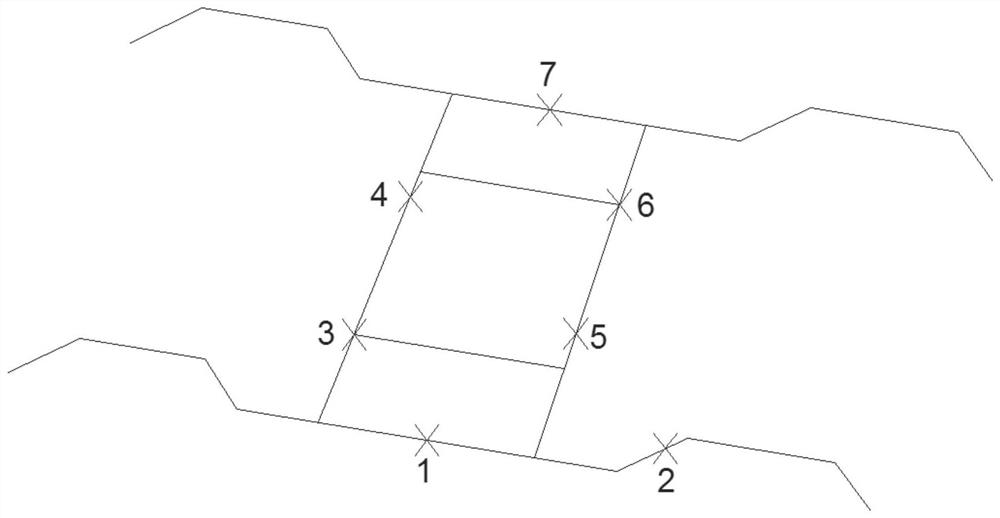

[0047] The present invention aims to propose a method for estimating the fatigue life of rail train bogies. The present invention calculates the theoretical stress of the monitoring point after the external load is applied through the method of finite element simulation, and uses the stress superposition theory to solve the coefficient of the stress of each monitoring point and the external load. matrix. Then, the stress value during the actual operation of the train is monitored by adding a stress acquisition sensor, and the coefficient matrix calculated by the theoretical method is used to invert the force of the train during the actual process. Finally, the stress history of the frame is obtained by loading the actual force into the theoretical model. , the fatigue life of the weak point of fatigue life is calculated, that is, the fatigue life of the frame.

[0048] Such as figure 1 Shown, a kind of railway train bogie fatigue life estimation method of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com