Vertical machining center with novel moving part protective cover

A vertical machining center and moving parts technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools and other directions, can solve the problems of occupying a large space and affecting the finishing structure of machine tool castings, and achieve a small occupied size and a good human body. Engineering design features, the effect of increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

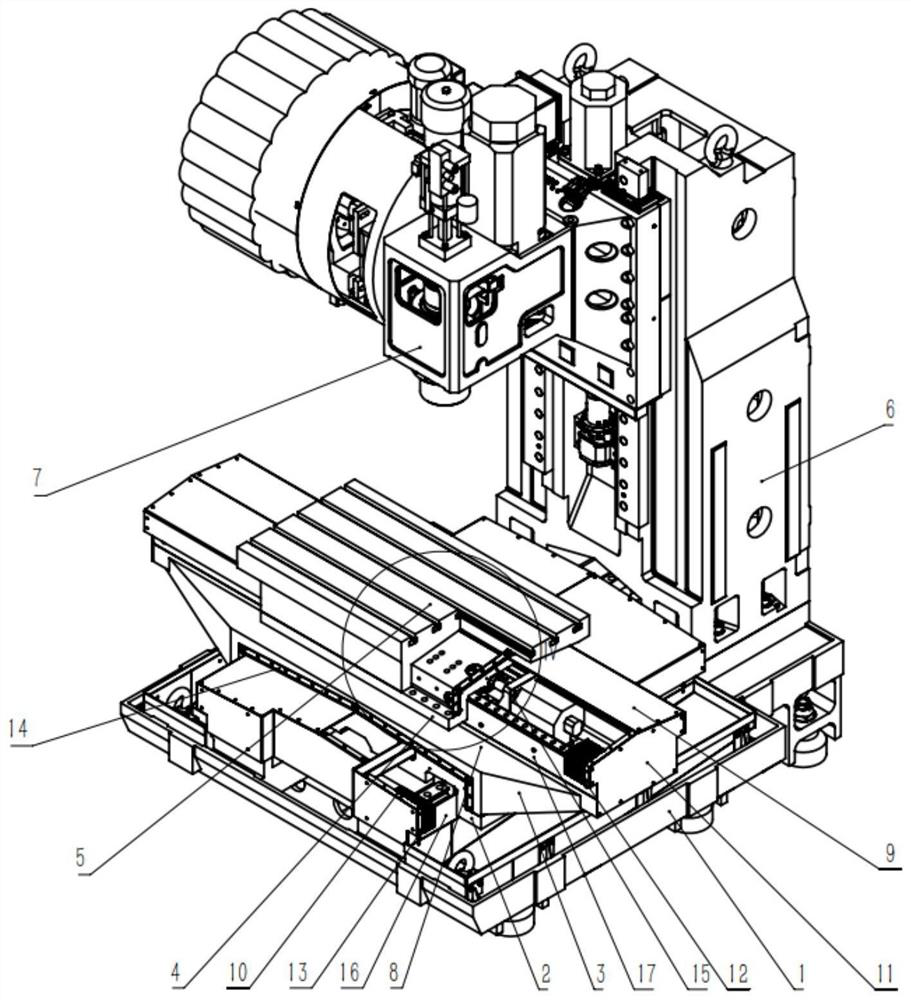

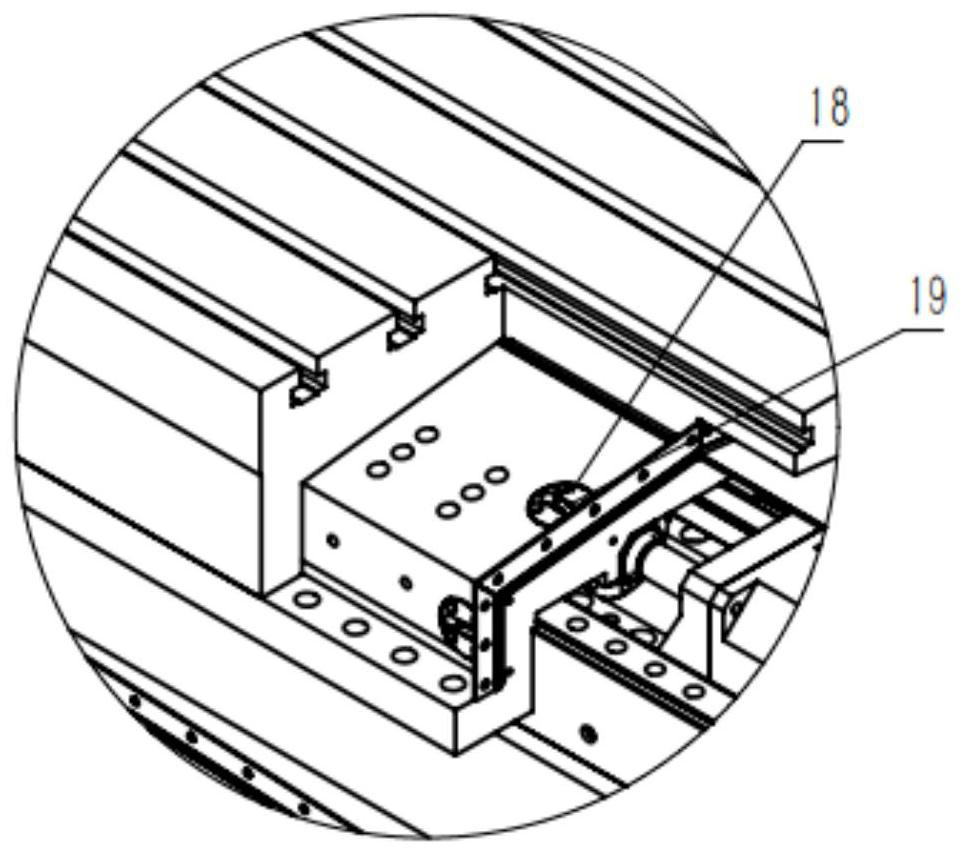

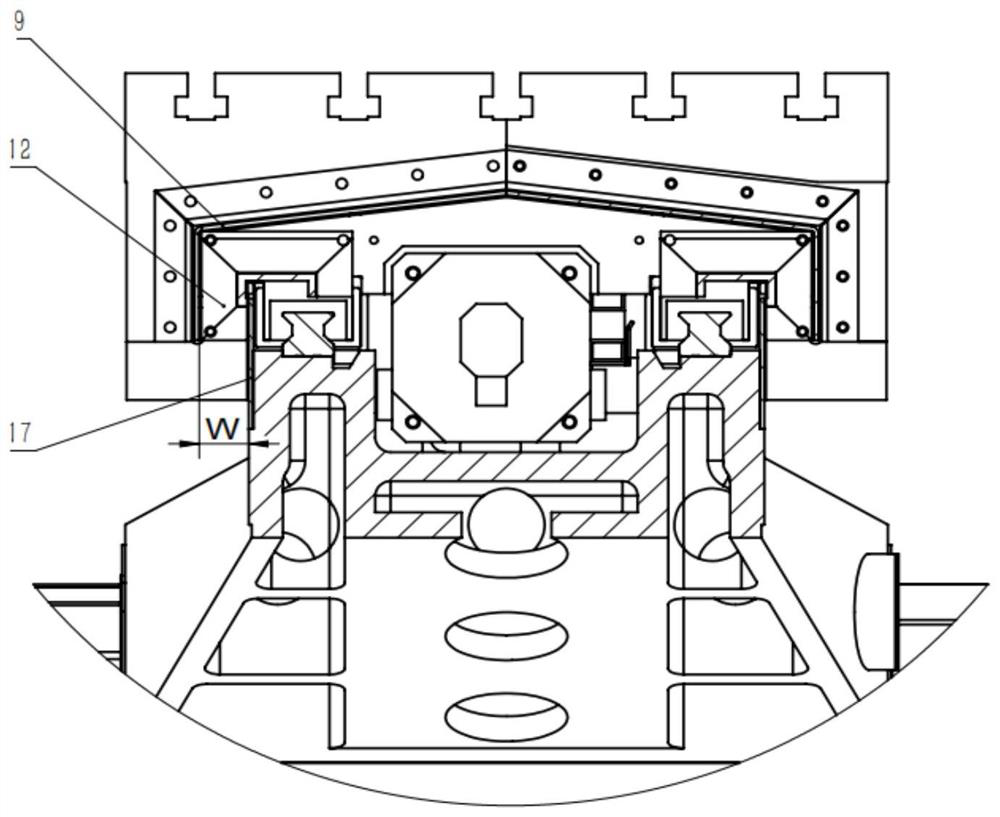

[0028] The invention provides a vertical machining center with a new type of protective cover for moving parts, which is characterized in that: the vertical machining center with a new type of protective cover for moving parts includes a bed 1, a base 2, a slide 3, Base 2 4, workbench 5, column 6, headstock 7, new guard 1 8, new guard 2 9, support plate 10, support plate 2 11, small organ cover 12, small organ cover 2 13, scraping Chip plate one 14, scraping plate two 15, side baffle plate 1 16, side baffle plate 2 17, roller support seat 18, roller 19;

[0029] Among them: the bed 1 is connected with the base 1 through a linear guide rail to realize the reciprocating movement of the base 2 along the Y direction; the base 2 is connected with the sliding seat 3 to drive the sliding seat 3 to reciprocate along the Y direction; 2 and 4 are connected to realize the reciprocating movement of the base 2 and 4 along the X and Y directions, and the workbench 5 is connected with the ba...

Embodiment 2

[0042] The invention provides a vertical machining center with a new type of protective cover for moving parts, which is characterized in that: the vertical machining center with a new type of protective cover for moving parts includes a bed 1, a base 2, a slide 3, Base 2 4, workbench 5, column 6, headstock 7, new guard 1 8, new guard 2 9, support plate 10, support plate 2 11, small organ cover 12, small organ cover 2 13, scraping Chip plate one 14, scraping plate two 15, side baffle plate 1 16, side baffle plate 2 17, roller support seat 18, roller 19;

[0043] Among them: the bed 1 is connected with the base 1 through a linear guide rail to realize the reciprocating movement of the base 2 along the Y direction; the base 2 is connected with the sliding seat 3 to drive the sliding seat 3 to reciprocate along the Y direction; 2 and 4 are connected to realize the reciprocating movement of the base 2 and 4 along the X and Y directions, and the workbench 5 is connected with the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com