Flat sheet membrane assembly capable of forming water outlet and circulation channels after being spliced

A circulation channel and flat membrane technology, applied in the direction of membrane, membrane technology, semi-permeable membrane separation, etc., can solve problems such as inconvenient plugging, troublesome assembly, easy aging of hoses, etc., to improve water flow and increase water flow. Water flux, easy and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

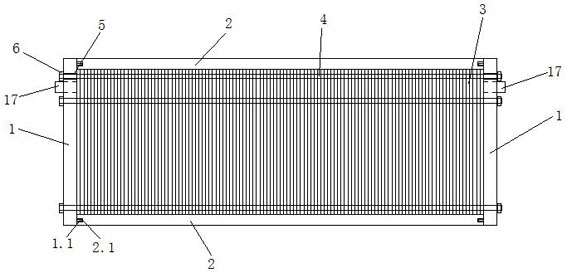

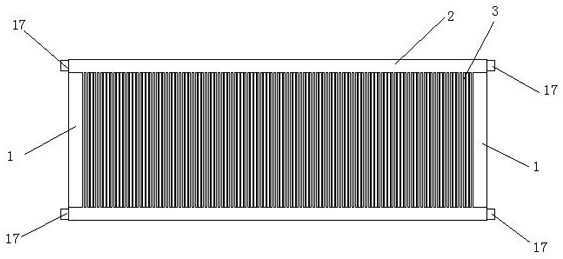

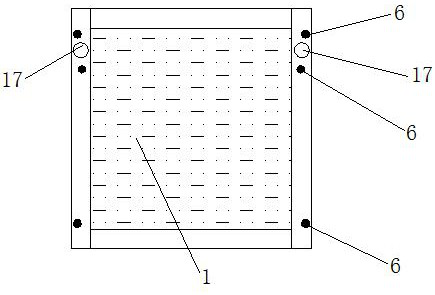

[0030] Embodiment 1: as figure 1 , 2, 3, 4, 5, 6, 7, 8, and 9, a flat membrane module that can form water outlet and circulation channels after splicing includes two side plates 1 and a number of limit bars 2 connecting the two side plates 1, the side The plate 1 and the limit bar 2 are inserted through the concave-convex structure. Preferably, the two ends of the limit bar 2 are provided with jacks 2.1, and the side plate 1 is provided with a convex bar 1.1 for inserting into the limit bar jack 2.1. A number of flat film 3 are clamped between them; the two side plates 1 are connected by tension rods 4, and the two ends of the tension rod 4 are provided with external threads, and the two side plates 1 are provided with through holes for passing through the tension rods 4 5. The two ends of the tension rod 4 pass through the two side plates 1 and lock the two side plates 1 through the nuts 6; the flat membrane 3 includes the membrane element support plate 7 and the guide cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com