Badminton racket string

A badminton line and horizontal line technology, applied in the field of badminton, can solve the problems of affecting the force transmission efficiency, friction and breakage of the horizontal or vertical lines, and displacement of the beat line, so as to improve the force transmission efficiency, reduce friction and prolong life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

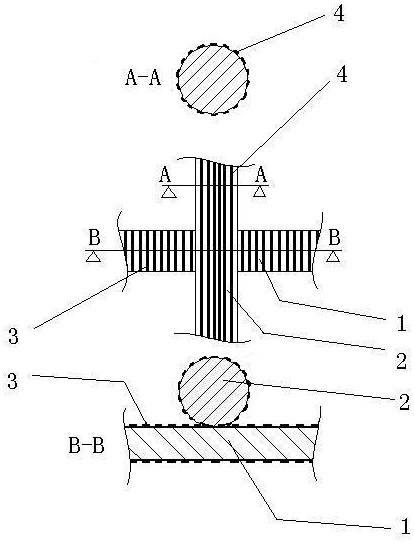

[0011] figure 1 Among them, a badminton line, which consists of a horizontal line and a vertical line, is characterized by:

[0012] A badminton line consists of a horizontal line 1 with a diameter of 0.7mm and a length of 5m and a vertical line 2 with a diameter of 0.7mm and a length of 5m; the core materials of the horizontal line 1 and the vertical line 2 are both Chemically synthesized multi-layer resin, the outer layer materials are all resin braided fibers; the surface of the horizontal line 1 fiber is sprayed with two layers of hydrogen-titanium alloy coating, and the first layer of the horizontal line is evenly sprayed with a hydrogen-titanium alloy coating with a thickness of 50 microns , the second layer of coating 3 on the horizontal line is sprayed with a 100-micron thick hydrogen-titanium alloy coating at an interval of 0.2 mm along the length of the line. Horizontal line concave-convex coating; the surface of the vertical line 2 fiber is sprayed with two layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com