Meat soaking machine

A technology for dipping and meat, applied in the directions of food drying, food forming, food science, etc., can solve the problems of long cleaning and draining time, large space and investment, long pickling period, etc. Short drying time and high pickling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

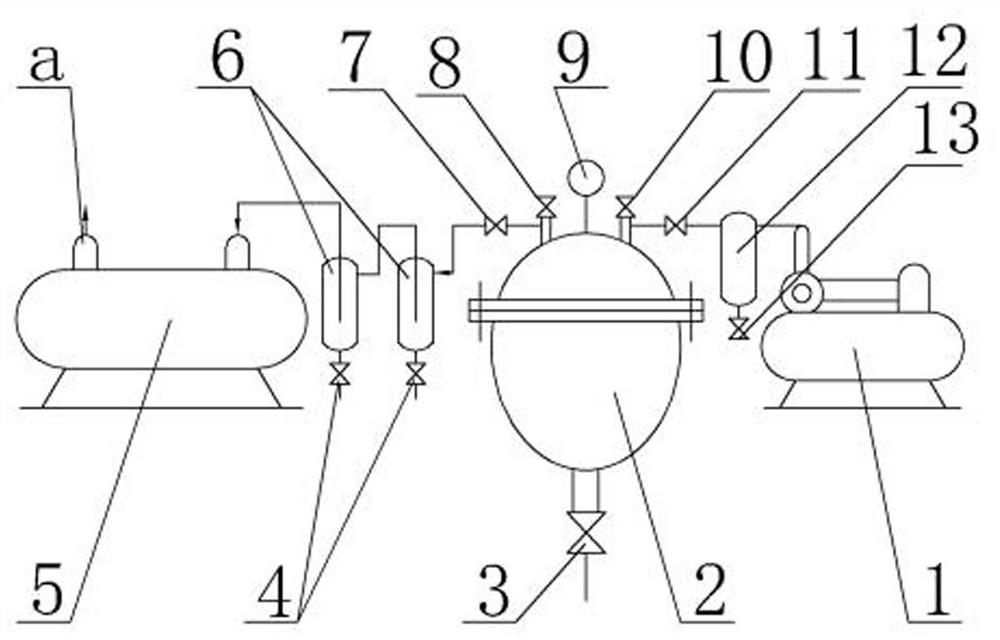

[0016] As shown in the accompanying drawings, the production kettle 2 is made up of a kettle cover and a kettle barrel, and the bottom of the kettle barrel is provided with a drain valve 3, through which water and other liquids in the kettle barrel are discharged through the drain valve 3. The kettle cover is provided with a pressure gauge 9, which can observe the pressure in the kettle 2 in real time.

[0017] The lid of the kettle is provided with a pipeline connected with the vacuum pump 5, and the pipeline is provided with a control valve 8, a vacuum valve 7, and a water-gas separator 6 in sequence. 7 Realize the disconnection between the inner cavity of the production kettle 2 and the vacuum pump 5, and the water-gas separator 6 separates the gas and water extracted from the production kettle 2. Start the vacuum pump 5, the gas and moisture in the production kettle 2 are quickly extracted, the water is discharged from the control valve 4 provided below the water-gas separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com