Microsphere inner surface defect measurement method

A measurement method and inner surface technology, applied in the field of optical inspection, can solve problems such as defocusing of inner surface defects, and achieve the effect of avoiding installation and adjustment errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

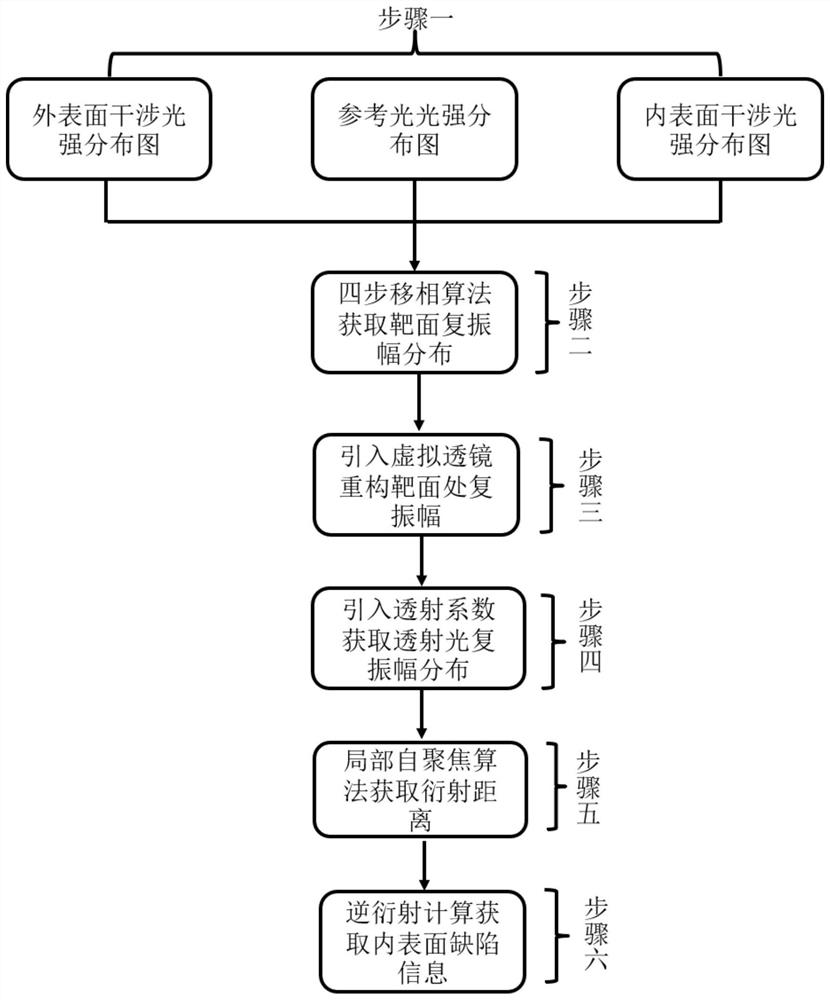

[0051] Such as figure 1 As shown, a method for measuring internal surface defects of microspheres, the specific steps are as follows:

[0052] Step 1: Use the microsphere inner surface defect measuring device to obtain the interference intensity map of the test light and the reference light on the outer surface of the microsphere, the interference intensity map of the test light and the reference light on the inner surface of the microsphere, and the light intensity distribution map of the reference light.

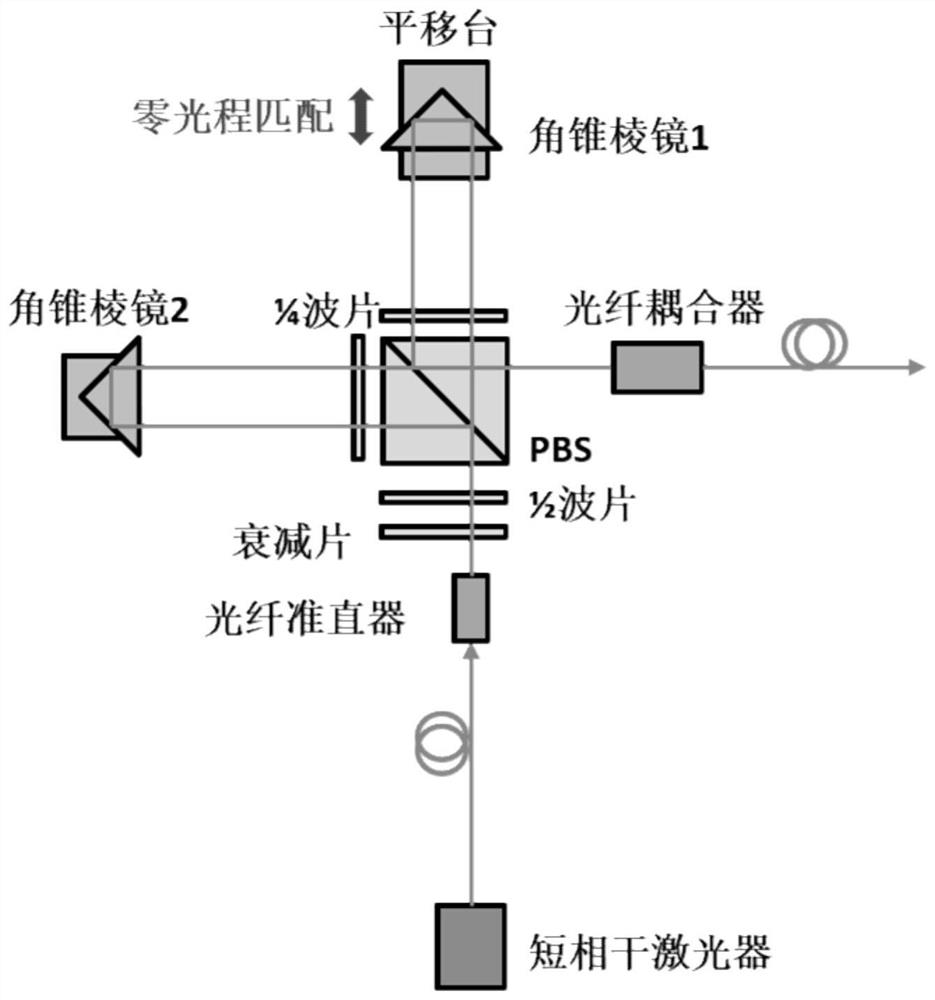

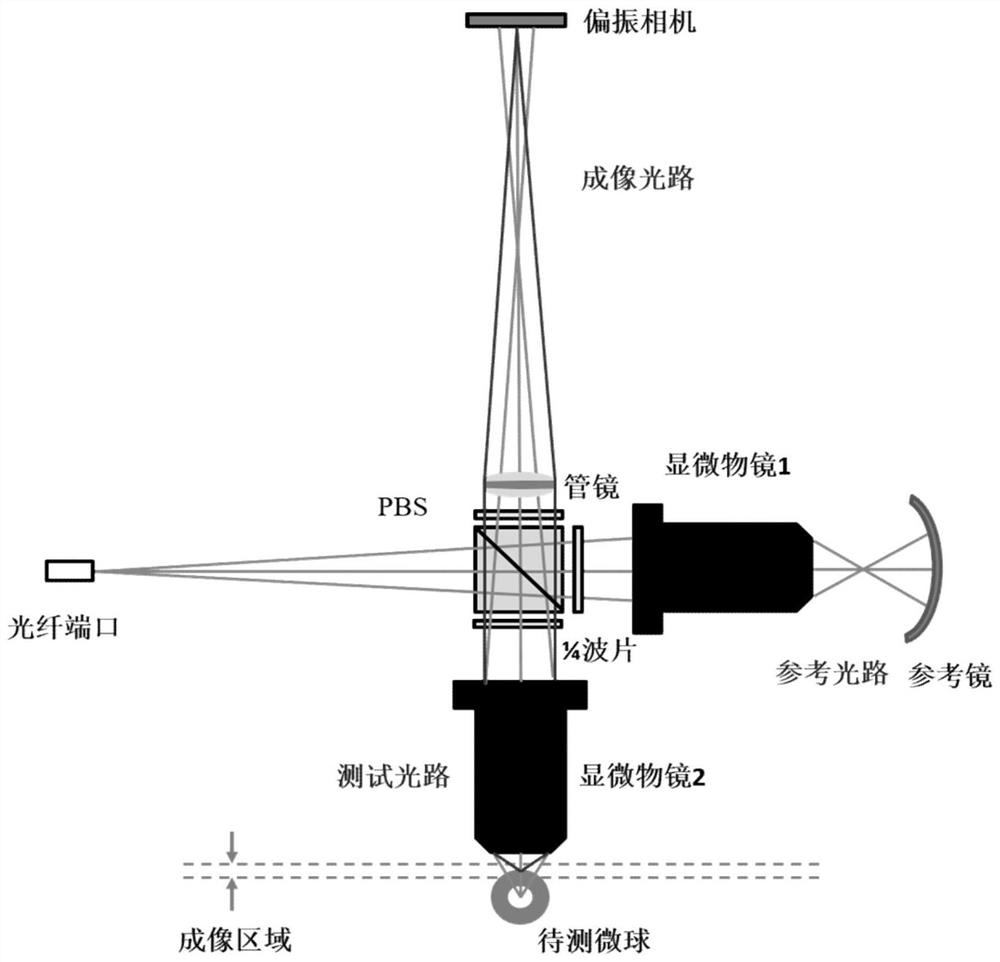

[0053] The microsphere inner surface defect measuring device includes two parts: a short-coherent light source module and a micro-interference imaging measurement module. Such as figure 2 As shown, the light emitted by the short-coherent laser in the short-coherent light source module passes through the attenuator and the 1 / 2 wave plate, where the 1 / 2 wave plate is used to adjust the amplitude ratio of the subsequent S light and P light, and then passes through the PBS polariz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com