A hardware self-calibration system and method for resolver angle measurement error

A resolver and self-calibration technology, applied in automatic recalibration, testing/calibration devices, instruments, etc., can solve the problems affecting the resolution of the resolver angle measurement, inconsistent sine and cosine signal amplitudes, affecting the control accuracy of the servo system, etc. easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further elaborated below in conjunction with embodiment.

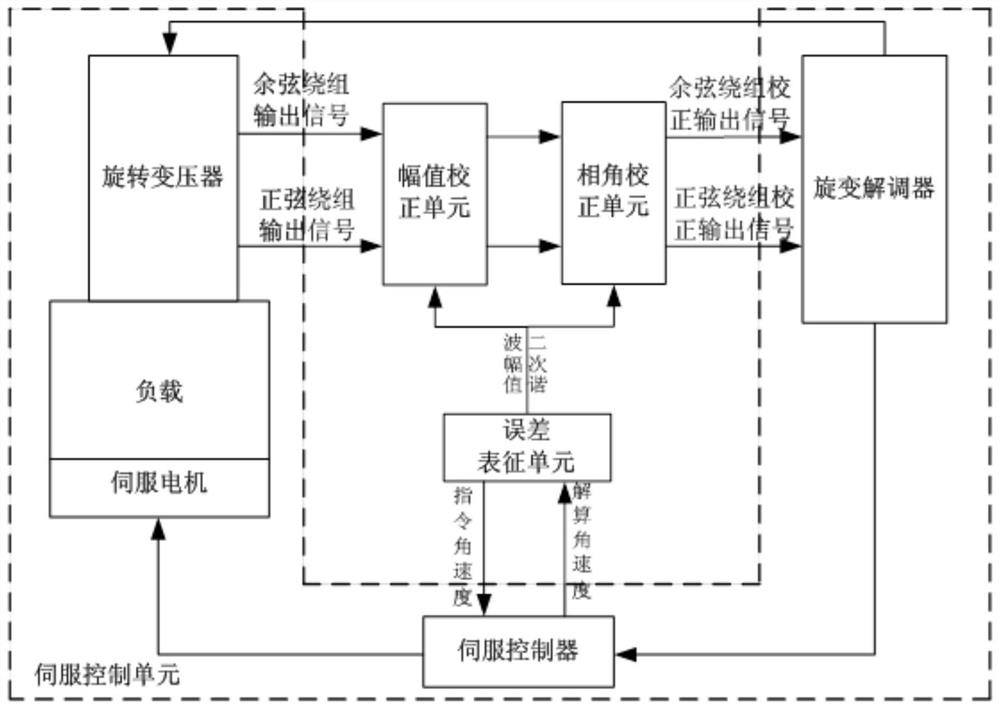

[0053] like figure 1 As shown, a resolver angle measurement error hardware self-correction system of the present invention includes: a servo control unit, an amplitude correction unit, a phase angle correction unit, and an error characterization unit;

[0054] The servo control unit is used to control the load to rotate stably according to the commanded angular velocity.

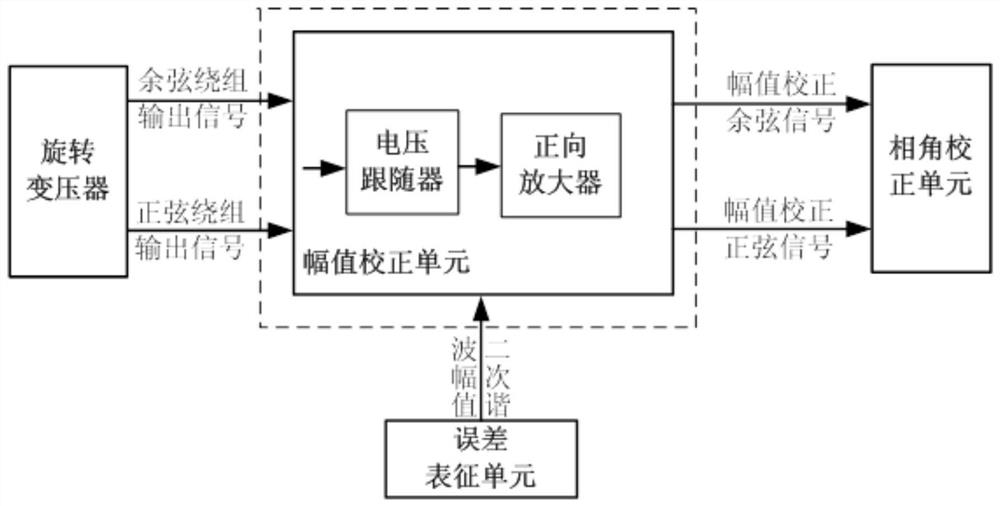

[0055] The amplitude correction unit is used to adjust the amplitude of the output signal of the sine-cosine winding output by the resolver to eliminate the amplitude error.

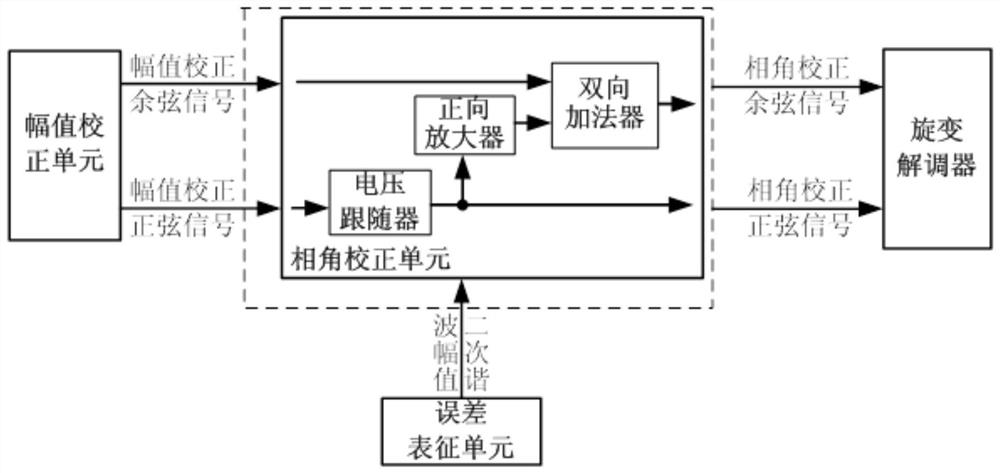

[0056] The phase angle correction unit is used to adjust the phase difference of the resolver output sine and cosine winding output signals to eliminate non-orthogonal errors.

[0057] The resolver error characterization unit sends command angular velocity to the control servo control unit, conducts frequency spectrum analysis on the resol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com