Variable-section cantilever formwork suitable for rapid construction and construction method adopting variable-section cantilever formwork

A construction method and formwork technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of fixed size and unsuitability for special high-altitude operations, and achieve the effect of easy hoisting, green construction requirements, and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with specific embodiments.

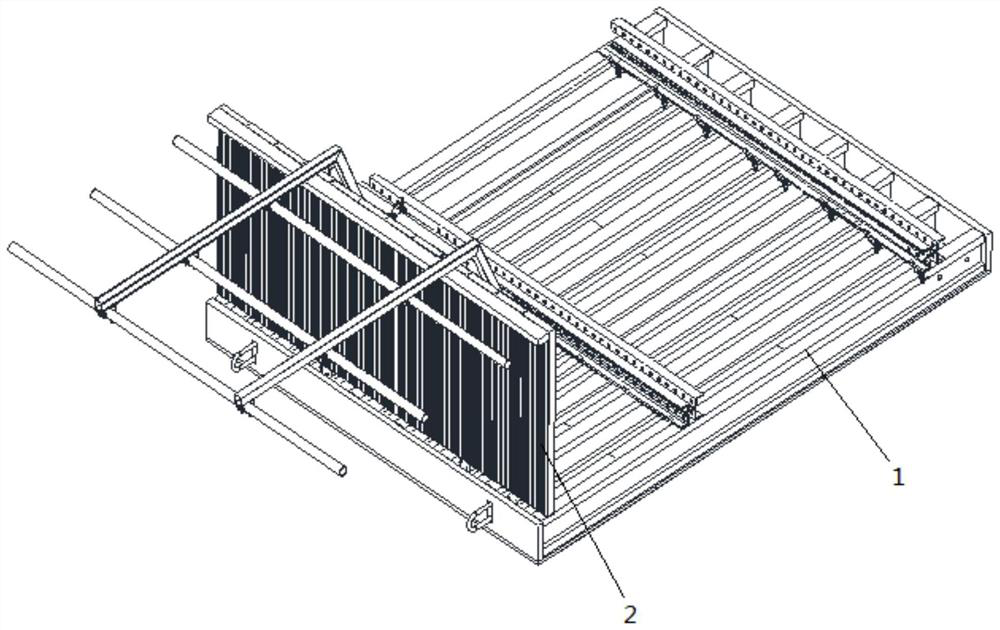

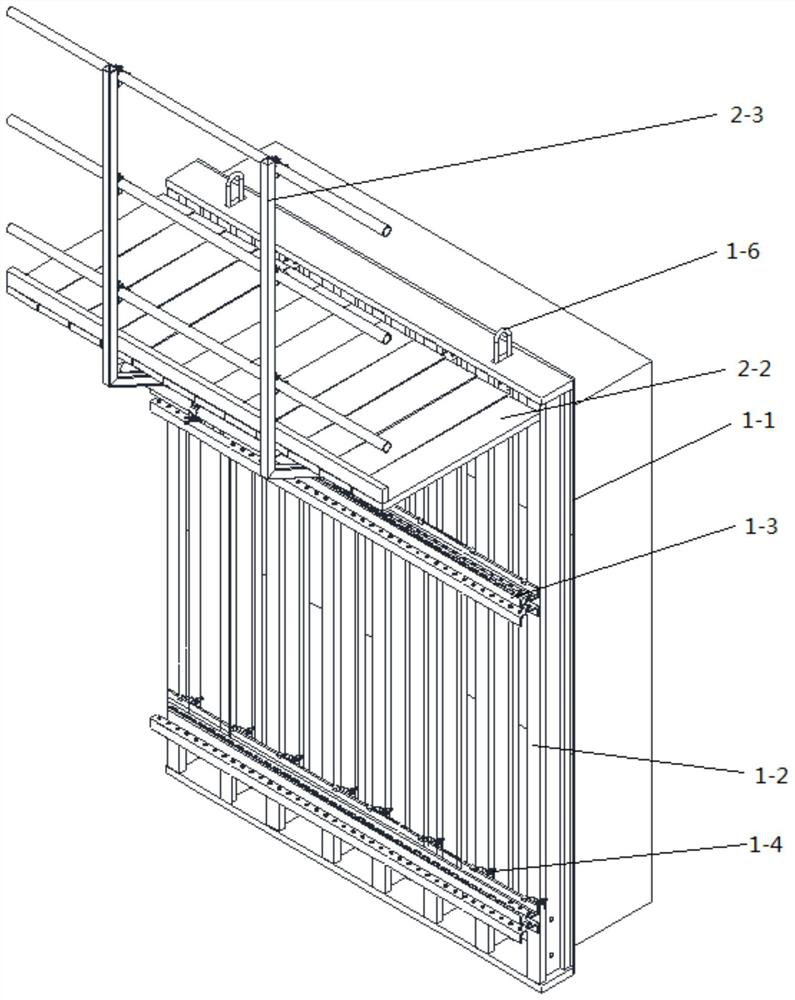

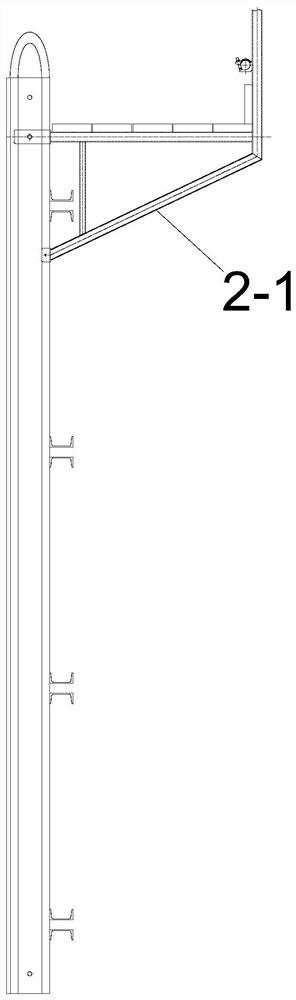

[0048] A variable-section cantilever formwork suitable for rapid construction, including a formwork system, an operating platform, and a connection system.

[0049] The formwork system includes multiple formwork units, and each formwork unit includes panels, I-beams, channel steel, connecting claws, bolts, steel nails, and hooks. In this embodiment, the panel adopts a 21mm multi-layer board. The length direction of the wooden I-beam is set along the height direction of the panel, and multiple wooden I-beams are arranged at intervals along the width direction of the panel, and the wooden I-beam is fixed on the panel by steel nails; the length direction of the channel steel is along the width direction of the panel It is provided that at least two channel steels are arranged at intervals along the height direction of the panel, and the channel steels are detachably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com