Warping machine yarn traction device

A traction device and warping machine technology, applied in warping machines, other manufacturing equipment/tools, textiles and paper making, etc. Guarantee the effect of humidification, avoid waste of water resources, and avoid waste of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

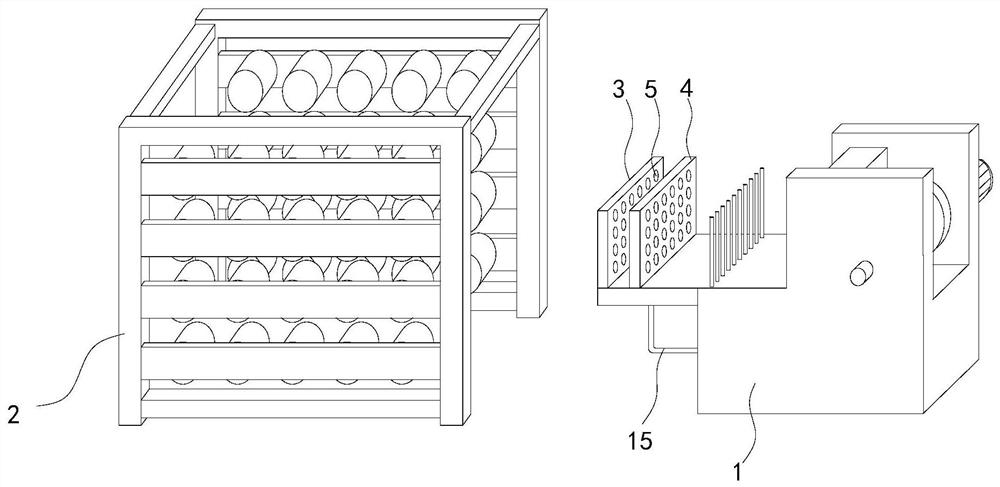

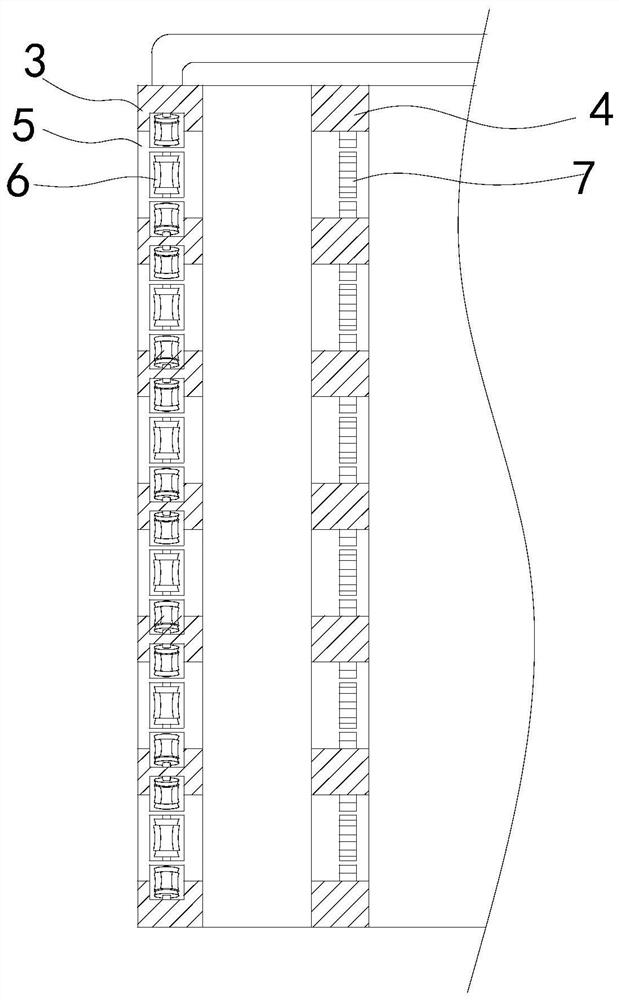

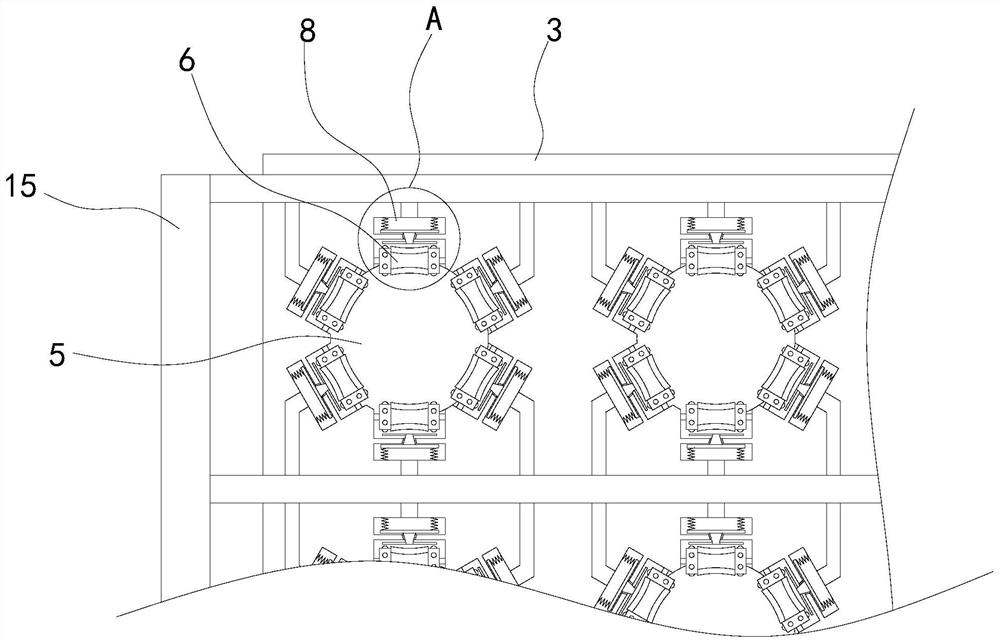

[0025] See Figure 1 to 7 , A schematic diagram of a plane structure and a schematic diagram of a three-dimensional structure of a yarn pulling device of a warping machine.

[0026] A yarn pulling device of a warping machine includes a warping winder 1, a warping humidifying device 3 is fixedly installed on the left side of the warping winder 1, and a humidifying wheel 6 is fixedly installed inside the warping humidifying device 3. A through hole 5 is opened inside the humidification device 3, and a warping and de-flocculation device 4 is fixedly installed on the right side of the warping humidification device 3.

[0027] In the specific implementation, the humidification wheel 6 is equidistantly arranged on the inner wall of the through hole 6 in the warping and humidification device 3, and the middle end of the humidification wheel 6 is arranged in an arc-shaped concave shape, so that when the yarn on the yarn creel 2 When the thread passes through the warping and humidification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com