Ducted propeller support partition pre-swirl deflector

A technology of deflector and ducted propeller, which is applied in transportation and packaging, ship construction, ship propulsion, etc. It can solve the problems of reduced propulsion efficiency, large flow unevenness, propeller cavitation, etc., and can improve vibration and cavitation performance , Improve propulsion efficiency, and flexibly adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

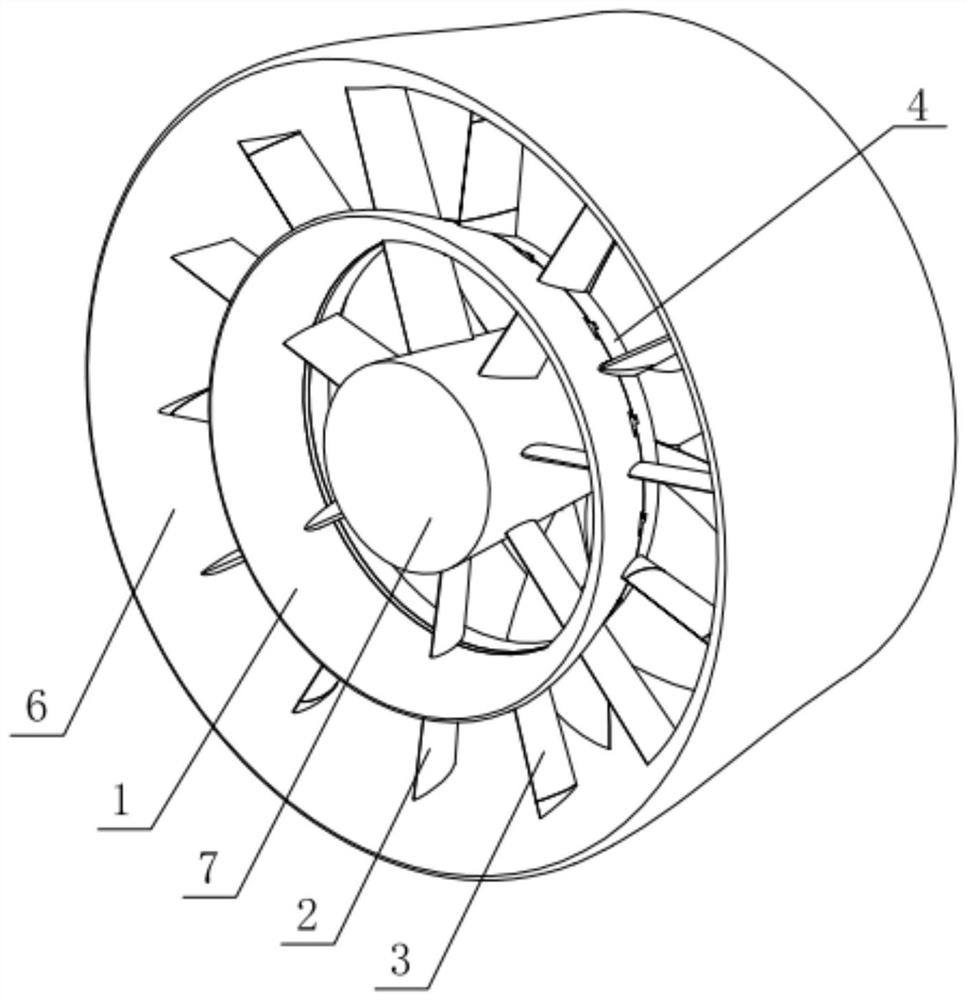

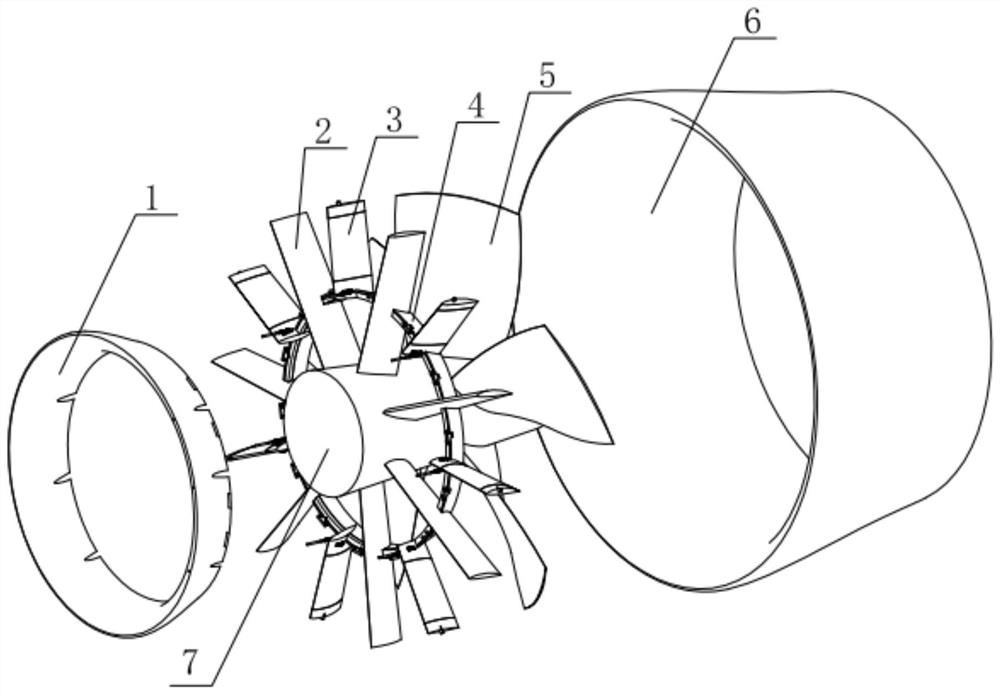

[0046] The deflector 3 is located between the deflector ring and the inner wall of the conduit 6 .

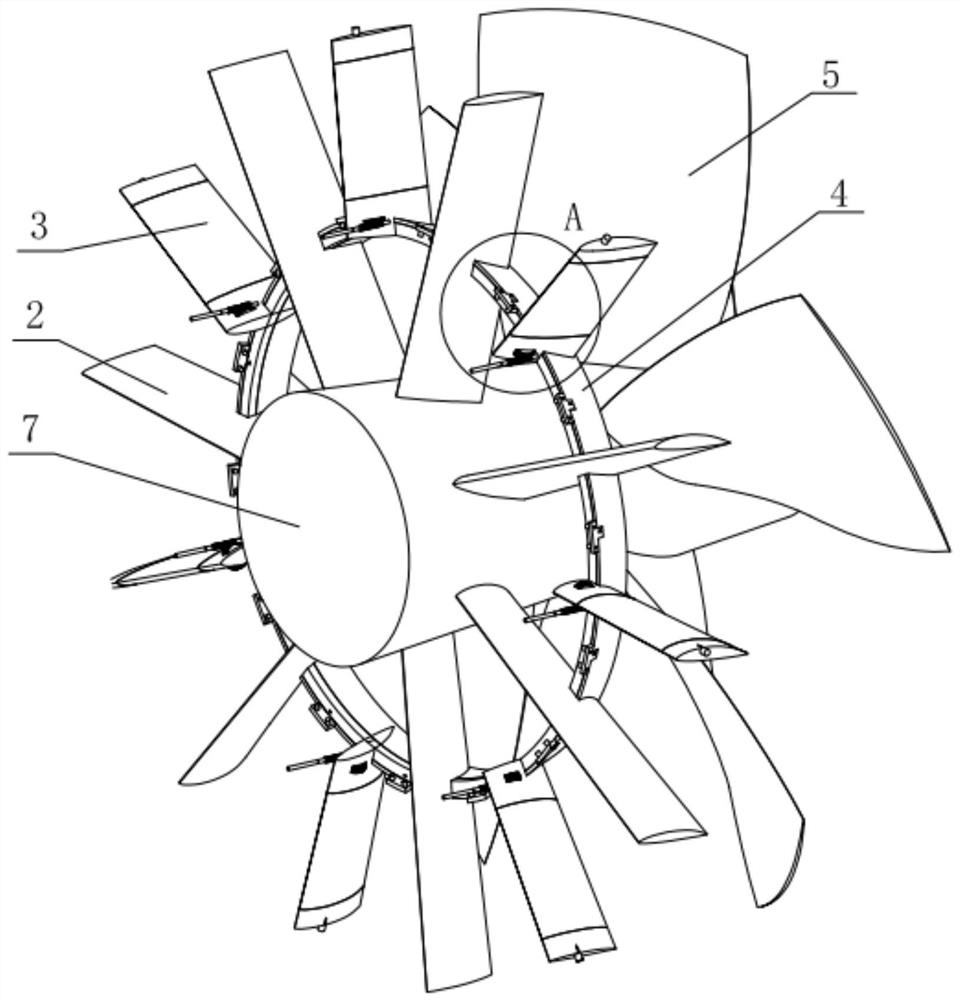

[0047] The outer guide vane 33 is fixed on the inner wall of the duct 6, and the inner guide vane 34 is embedded on the wall of the guide ring; the adjustment mechanism 9 is installed between the guide ring and the inner guide vane 34, and the worm wheel 91 moves along Tangentially through the inner guide vane 34 wall, one end of the worm 92 meshes with the worm wheel 91, and the other end of the worm 92 extends to the outside of the guide ring.

[0048] The inner guide vane 34 is provided with a through groove 341 for the worm wheel 91 to pass through, and the inner top surface of the through groove 341 is provided with a circular hole penetrating upwards, and the rotating shaft 32 at the bottom of the movable guide vane 31 is accommodated in the circular hole.

Embodiment 2

[0050] The deflector 3 is located between the deflector ring and the outer wall of the propeller hub 7 .

[0051] The inner guide vane 34 is fixed on the outer wall surface of the propeller hub 7, the outer guide vane 33 is embedded on the wall surface of the guide ring; the adjustment mechanism 9 is installed between the guide ring and the outer guide vane 33, and the worm wheel 91 moves along The tangential direction of the ring runs through the wall of the outer guide vane 33 , one end of the worm 92 meshes with the worm wheel 91 , and the other end of the worm 92 extends to the outside of the guide ring.

[0052] The guide ring and the guide vane 3 located inside or outside the guide ring realize the partition inside the ducted propeller. Through the partition pre-rotation guide device, especially the adjustable guide vane 3, the flow field in the area is realized. The flexible adjustment of the uniformity not only improves the propulsion efficiency of the propeller, but a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com