Reciprocating intelligent high-efficiency presser

A reciprocating and pressing technology, applied in the field of reciprocating intelligent high-efficiency presses, can solve the problems of low production efficiency and complicated operation, and achieve the effects of improving work efficiency, improving product quality and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

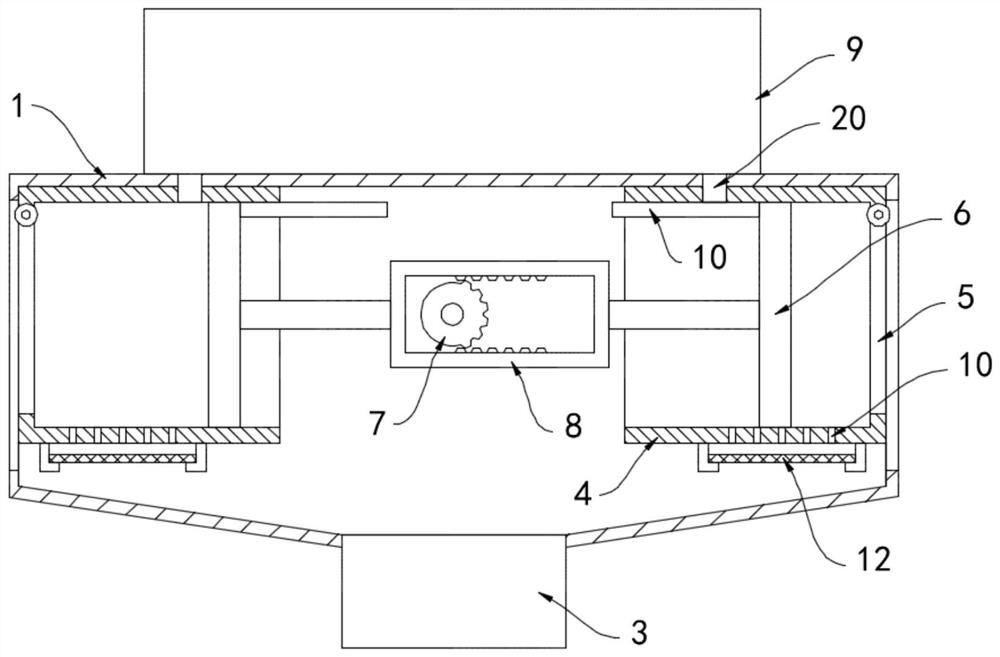

[0022] Such as Figure 1-2 As shown, a reciprocating intelligent high-efficiency press includes a housing 1 and a motor 2 installed in the housing 1. Both ends of the housing 1 are open, and the lower end of the housing 1 is equipped with an oil sump 3. The housing The bottom surface of 1 is provided with a downwardly concave arc surface, which is convenient for the squeezed vegetable oil to flow into the oil collection tank 3 .

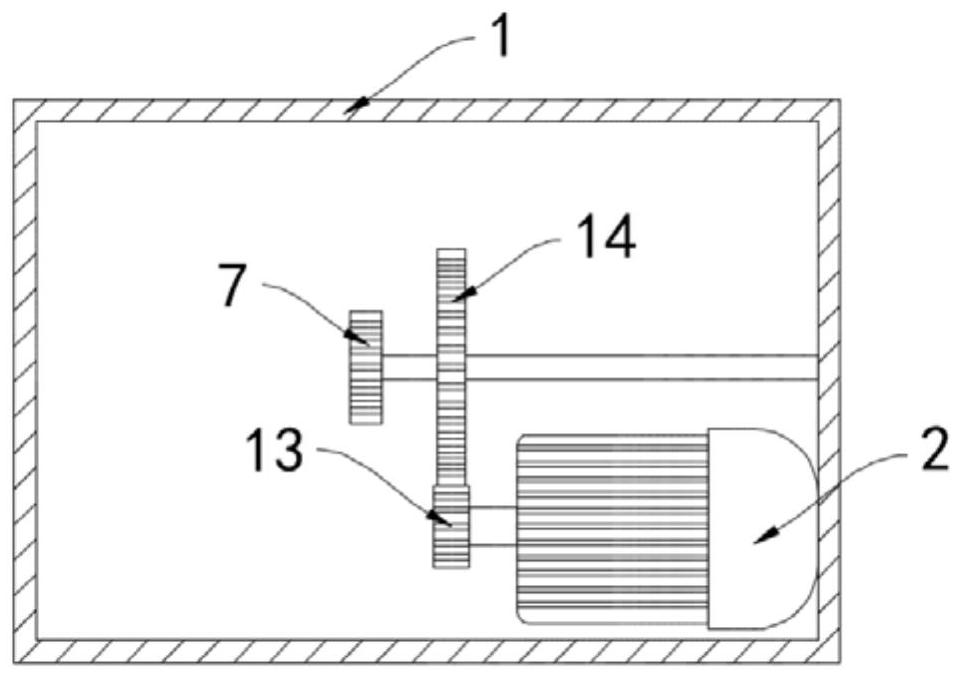

[0023] The inner walls of both sides of the housing 1 are fixedly connected with an oil extraction cylinder 4, and the side walls of the oil extraction cylinder 4 are hinged with a discharge door 5. There is a vertically arranged pressure plate 6 sliding horizontally in the oil extraction cylinder 4, and the motor 2. A half gear 7 is connected through a reduction mechanism. The reduction mechanism includes a drive gear 13 fixed coaxially with the output shaft of the motor 2. A reduction gear 14 is coaxially fixed on one side of the half gear 7. The r...

Embodiment 2

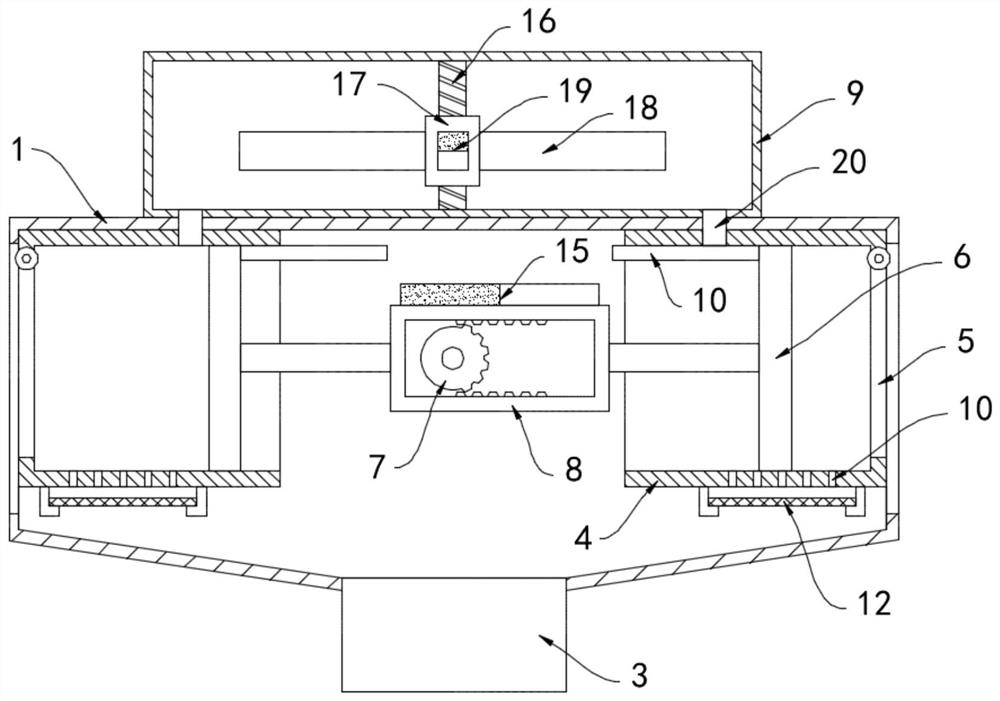

[0030] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the upper end of the movable frame 8 is provided with a bar magnet 15, and the two ends of the bar magnet 15 have opposite magnetic poles, and a vertically arranged magnet is fixedly installed in the storage box 9. Screw mandrel 16, screw mandrel 16 external threads are sleeved with screw mandrel nut 17, two push plates 18 are installed on the side wall of screw mandrel nut 17, and the lower end of screw mandrel nut 17 is fixedly connected with the permanent that matches with bar magnet 15. Magnetic block 19, the upper and lower ends of the permanent magnet block 19 have opposite magnetic poles.

[0031] In this embodiment, the bar magnet 15 can move back and forth with the movable frame 8, and then the opposite ends of the bar magnet 15 with magnetic poles alternately move to the right below the permanent magnet block 19 to generate periodic changes in the attraction of the perma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com