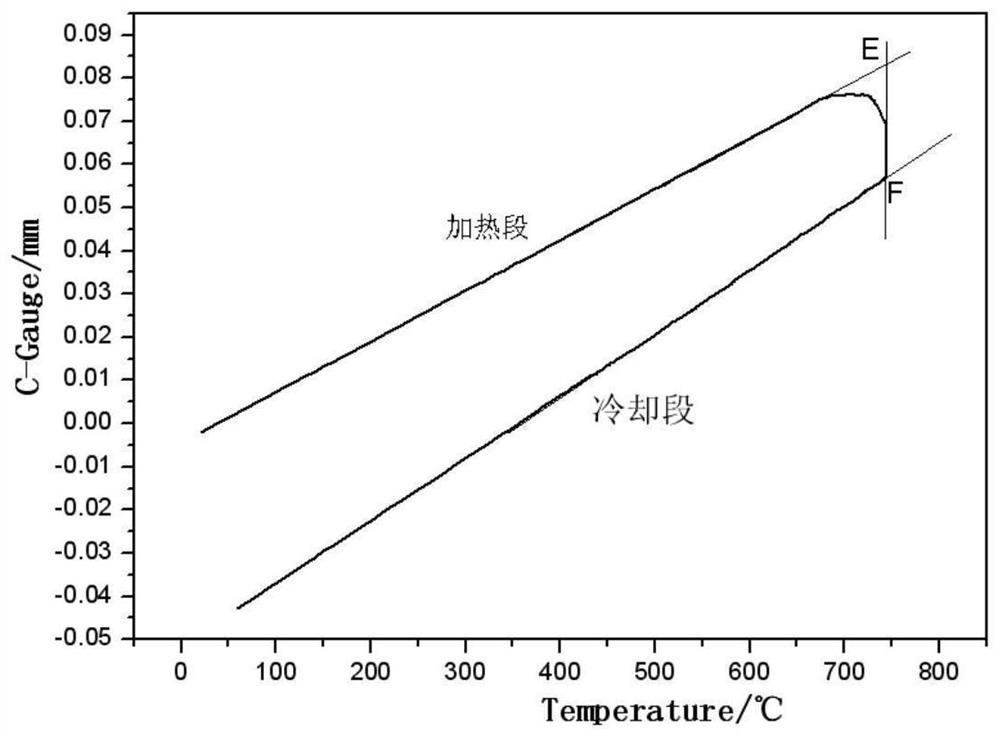

Method for determining reverse austenite by adopting expansion method

A technology of reverse transformation of austenite and expansion method, applied in the field of material metallurgy, to achieve the effects of ensuring smooth development, improving analysis efficiency, and simplifying the calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Using the Gleeble3800 thermal simulation testing machine, two groups of tests were carried out on the TRIP steel containing 5% Mn. The test temperatures were 650°C and 680°C respectively. The specific test process is as follows:

[0063] Step (1): Select a 60mm thick Mn5 steel plate to take a quarter of the steel plate and process it into a Φ6×76mm sample;

[0064] Step (2): Weld a thermocouple on the sample of Mn5 steel processed in step (1). The welding position of the thermocouple is the middle position of the sample axial direction, and ensure that the plane where the thermocouple is located is perpendicular to the axial direction of the sample. , put it into the Gleeble3800 thermal simulation test chamber, install the dilatometer, and the measuring blade of the dilatometer and the thermocouple are on the same plane.

[0065] Step (3) Use the Gleeble3800 thermal simulation testing machine to heat the sample installed in step (2) to a temperature of 800°C for 10 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com