Food conveying detection device and using method

A detection device, food technology, applied in packaging, transportation packaging, packaging protection and other directions, can solve the problems of inability to detect and screen food, and achieve the effect of solving low efficiency and improving error correction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

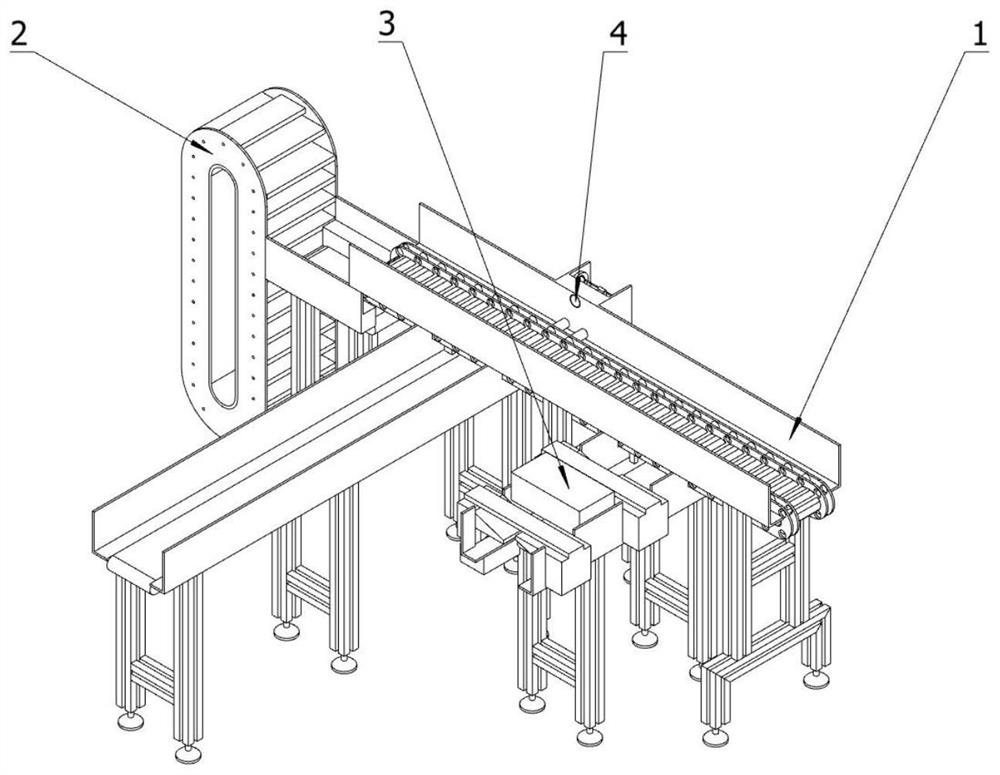

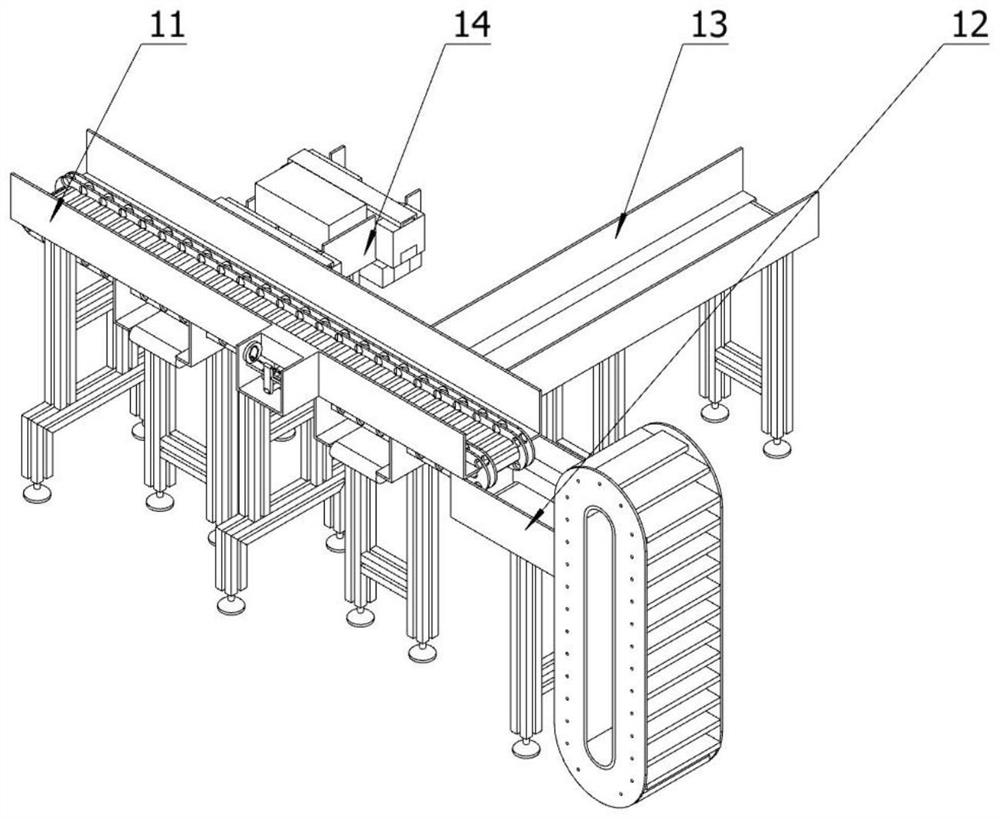

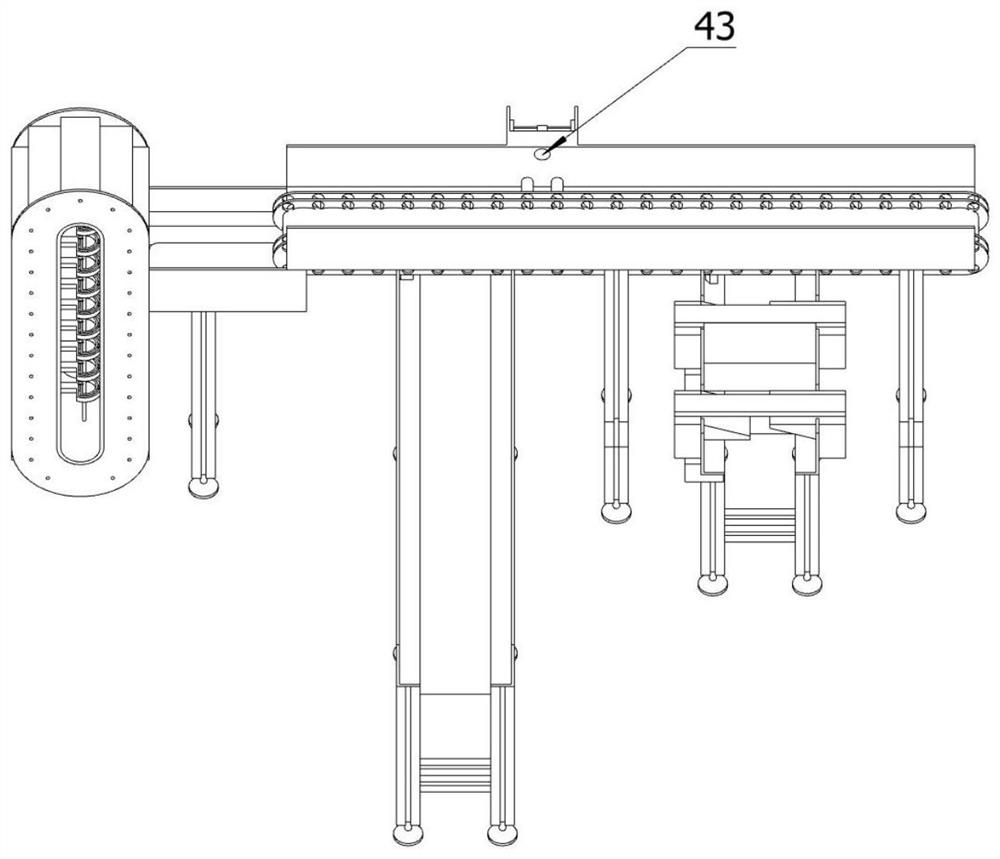

[0061] Such as figure 1 , 2 , 3, and 7, an automatic sewing device is characterized in that it includes: the main body 1 is placed on the ground, and the main body 1 includes a feeding conveyor belt 11, an unloading conveyor belt 12, a waste conveyor belt 13, and a sealing conveyor belt 14. The feeding conveyor belt 11 is fixed on the ground by two stainless steel brackets. The two sides of the feeding conveyor belt 11 are provided with baffles. The material belt 111 is connected between the feeding conveyor belts 11. The material belt 111 is located in the middle of the main body 1. There are wavy belts, and the concave-convex design of the wavy belt makes the packaging bag squeeze toward the recess when it is clamped, without causing extrusion damage. There are vertical plates with holes on both sides of the material belt 111. The push block 212 of the fixed propulsion device 41 ensures that the push block 212 cannot be fixed accurately when a problem is detected in the foo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com