A fracturing and sanding design method based on large-scale parallel plate proppant migration and placement model experiment

A proppant and parallel plate technology, which is applied in earthwork drilling, wellbore/well components, measurement, etc., can solve the problems of short hydraulic fracturing proppant migration distance and short effective propped fractures, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

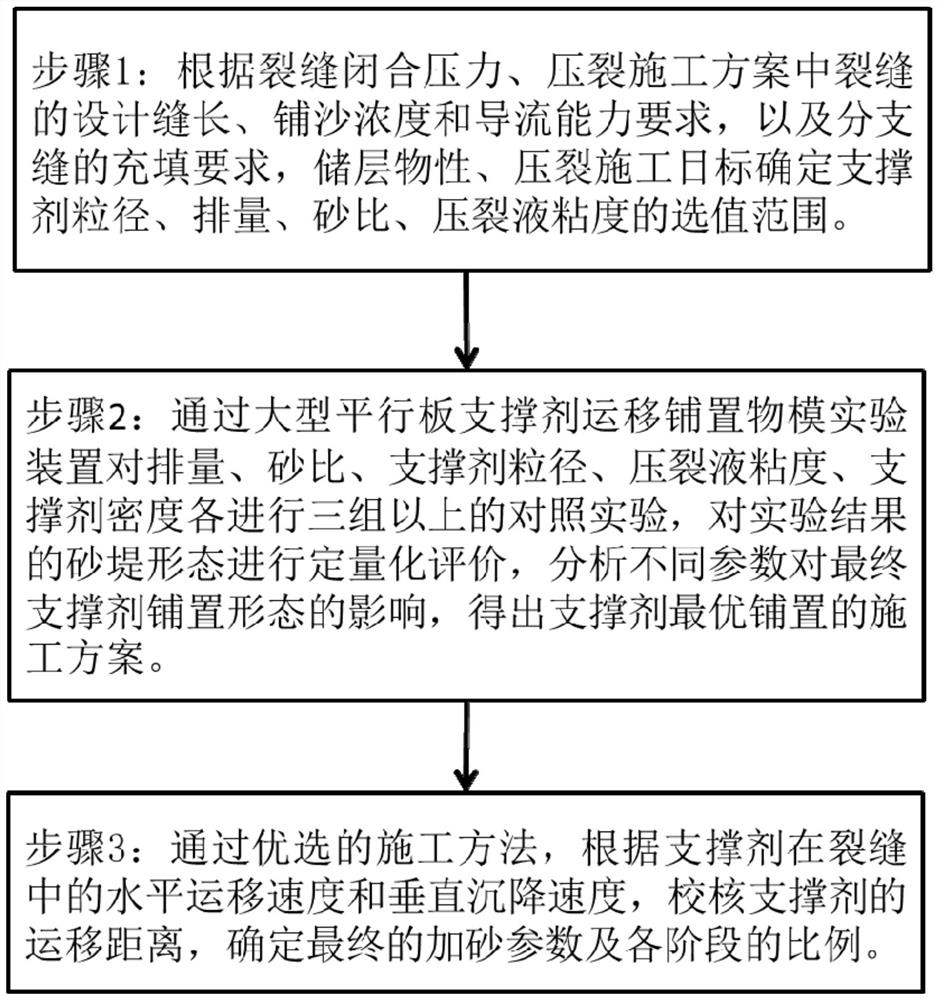

[0059] Taking oil well A with branch fractures as an example, to design the fracturing and sanding construction plan of oil well A, a fracturing and sanding design method based on the large-scale parallel plate proppant migration and laying physical model experiment is adopted, as shown in figure 1 As shown, it specifically includes the following steps:

[0060] Step 1: Select proppant particle size, fracturing fluid viscosity, proppant density, fracturing fluid displacement, and sand ratio as construction parameters, and determine the proppant particle size and fracturing fluid used in the early, middle, and late stages of fracturing construction. Value ranges of viscosity, proppant density, displacement, and sand ratio;

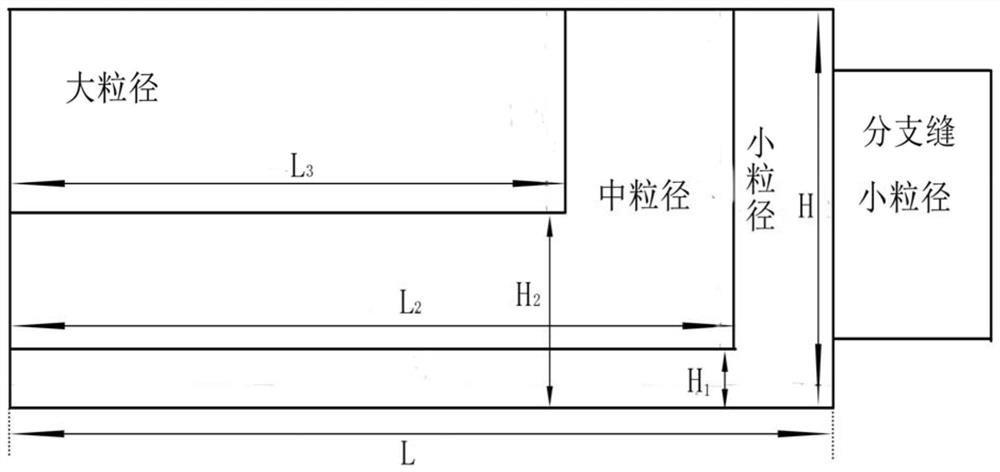

[0061] The fracture height H to be filled in oil well A is 10m, the fracture closure pressure is 40M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com