Hangar equipment for unmanned aerial vehicles

A technology of unmanned aerial vehicles and aircraft hangars, applied in the field of unmanned aerial vehicles, can solve the problems of low efficiency in the use of unmanned aerial vehicles and hangars, and achieve the effect of improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

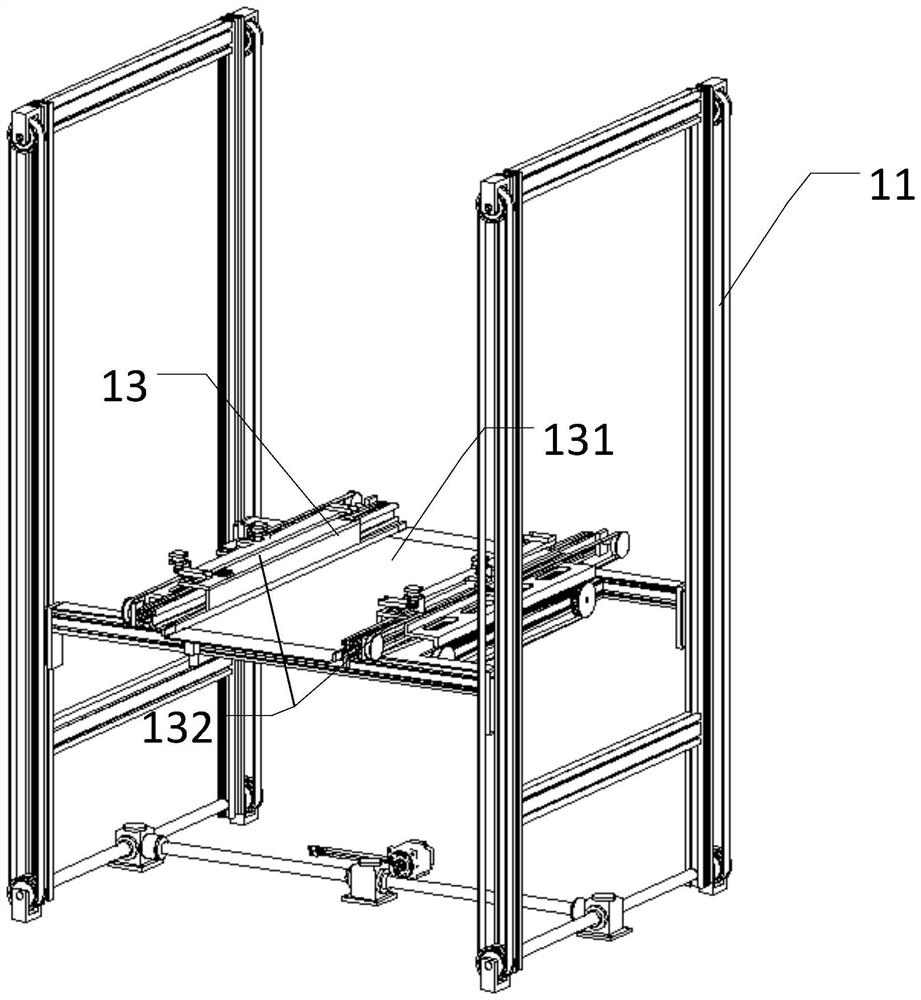

[0075] The X-axis guide rail 22 is arranged on one side of the battery rack 21 , and one end of the Z-axis guide rail 23 is arranged on the X-axis guide rail 22 , and the Z-axis guide rail 23 can move horizontally along the X-axis guide rail 22 . In one embodiment, the automatic battery replacement structure further includes a base 25 on which the battery rack 21 and the X-axis guide rail 22 are both arranged.

[0076] The Y-axis motion mechanism 24 includes a Y-axis guide rail 241 and a pick-and-place mechanism 242 , the Y-axis guide rail 241 is arranged on the Z-axis guide rail 23 , and the Y-axis guide rail 241 can move vertically along the Z-axis guide rail 23 .

[0077] The pick-and-place mechanism 242 is arranged on the Y-axis guide rail 241 , and the pick-and-place mechanism 242 moves along the Y-axis guide rail 241 along with the telescopic movement of the Y-axis guide rail 241 , and the pick-and-place mechanism 241 is used for grabbing or placing the battery.

[0078]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com