Twin hollow wall ceramic tile

A hollow wall and twin technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of large urban construction demand, high price, lack of sand, etc., and achieve the effect of beautifying urban and rural construction, high temperature resistance and compression resistance, and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

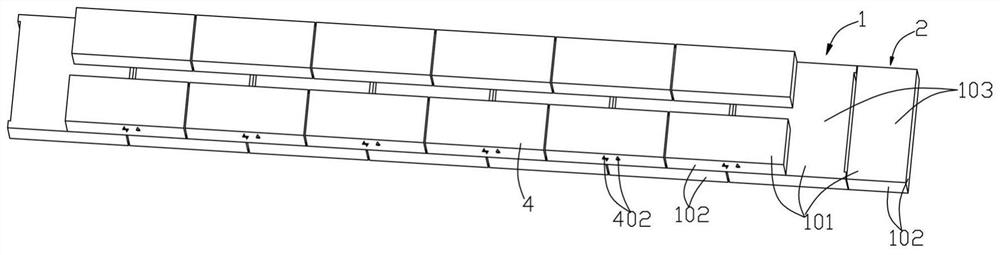

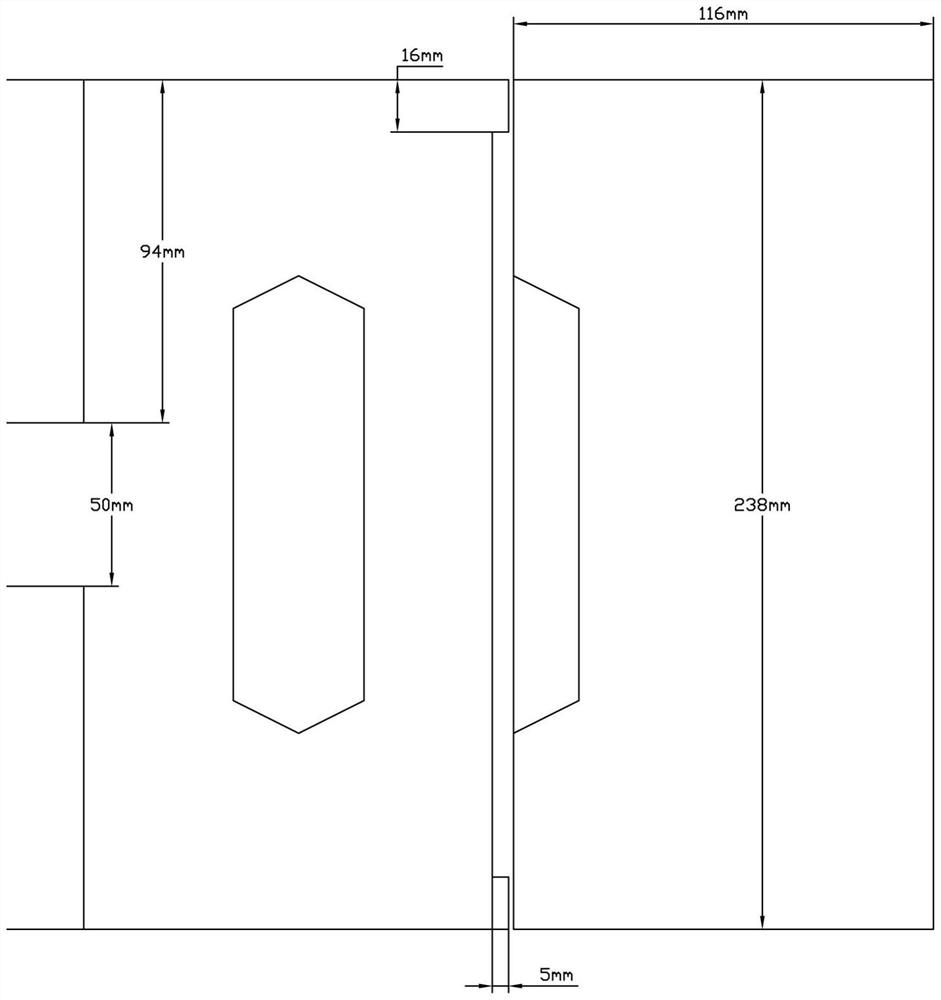

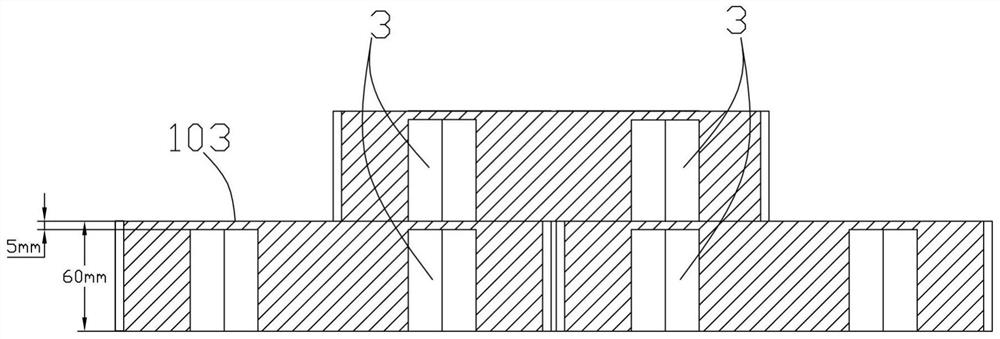

[0029] A kind of twin hollow wall ceramic tile, comprises main wall block 1, corner block 2, the upper and lower surfaces of described main wall block 1 and corner block 2 are stacking surface 101, and described main wall block 1 and corner block 2 are provided with There is a weight-reducing groove 3, the weight-reducing groove 3 of the corner block 2 is arranged on one side, the front and rear of the main wall block 1 are appearance sides 102, the two appearance sides of the corner block 2 are adjacent to each other 102, and the The main wall block 1 adopts a staggered tiled structure, that is, the center line of the upper main wall block 1 is aligned with the edge of the lower main wall block 1, and also includes a special block 4 for accessing water and electricity, and the main body of the special water and electricity block 4 is a rectangular parallelepiped block The hydropower special blocks 4 are symmetrically arranged in two groups, and the outer side of the symmetrica...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, except that a plurality of lightening holes 105 are uniformly arranged on the stacking surface 101 (such as Figure 8 shown). According to the required strength of different walls, the main wall block 1 provided with lightening holes 105 can be used to make the walls more environmentally friendly and energy-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com