Container turnover lifting appliance

A container and spreader technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of low work efficiency, large contact space, environmental pollution, etc., and achieve the effect of improving efficiency and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

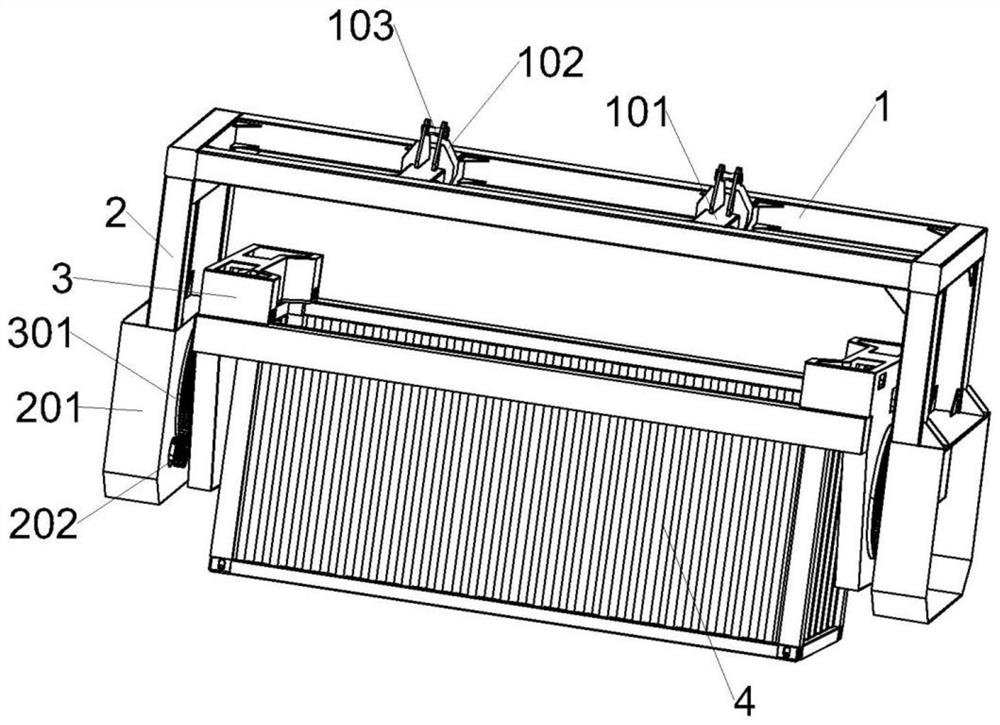

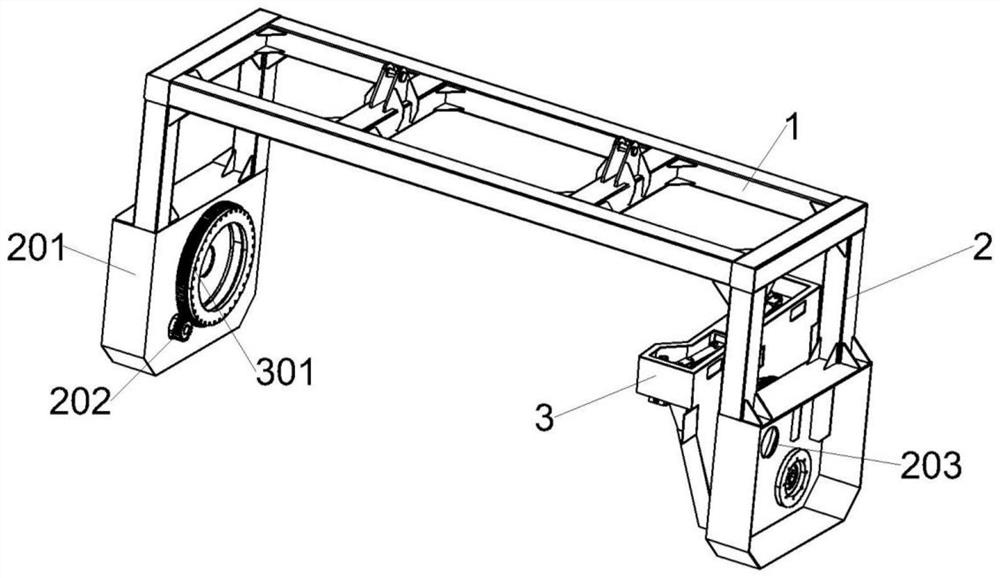

[0033] refer to Figure 1-7 As shown, this embodiment provides a container overturning spreader, including a container 4, a beam 1, a hook assembly fixedly arranged in the middle of the beam 1, a longitudinal beam 2 symmetrically fixed at both ends of the beam 1, and symmetrically arranged inside the longitudinal beam 2. The locking turning mechanism 3 and the driving mechanism that makes the locking turning mechanism 3 rotate, the driving mechanism is fixed on the bottom of the longitudinal beam 2, and the locking turning mechanism 3 is engaged with the driving mechanism. The lifting function of the container 4 is realized by the hook assembly, the container 4 and the spreader are locked by locking the turning mechanism 3, and the turning mechanism 3 is turned over by the driving mechanism to drive the container 4 to realize the turning function.

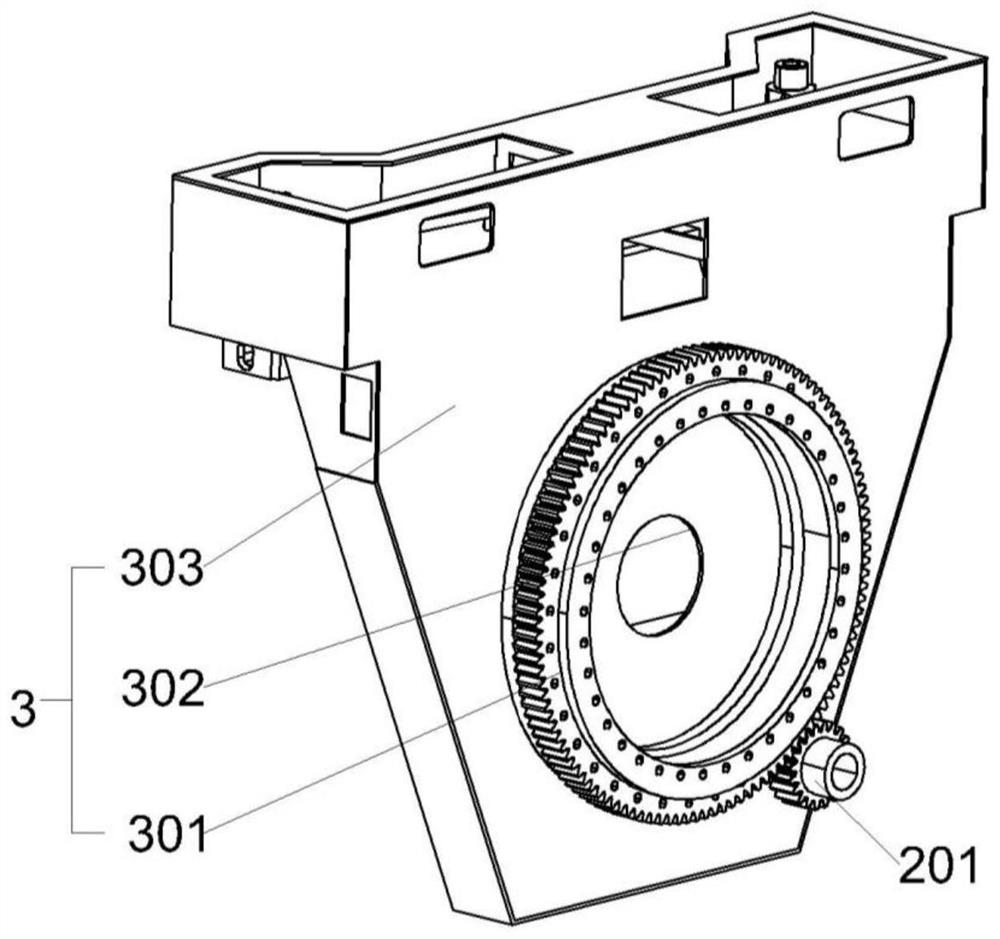

[0034] In a further optimized solution, the locking and turning mechanism 3 includes a first housing 303, a large gear 301 fixed ...

Embodiment 2

[0045] refer to Figure 8-11 As shown, the difference between the overturning spreader of this embodiment and the first embodiment is that the driving mechanism also includes a fixed block 3011 fixed on the side of the large gear 301, and the second housing 201 is provided with a space for making the fixed block 3011 move. slot 2011, a first pulley 2012 is fixed on the side of the second casing 201 close to the drive motor, a cylinder 2013 is fixed on the side of the second casing 201 away from the step-off groove 2011, and a second pulley 2014 is rotatably connected to the output shaft of the cylinder 2013. The top left of the cylinder 2013 is provided with a fixed rod 2015, the cylinder body of the cylinder 2013 is fixedly connected with the second housing 201, the fixed rod 2015 is fixedly connected with the second housing 201, the first pulley 2012 is arranged under the fixed block 3011, and the fixed block 2011 is fixed One end of the wire rope 8 is connected, the wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com