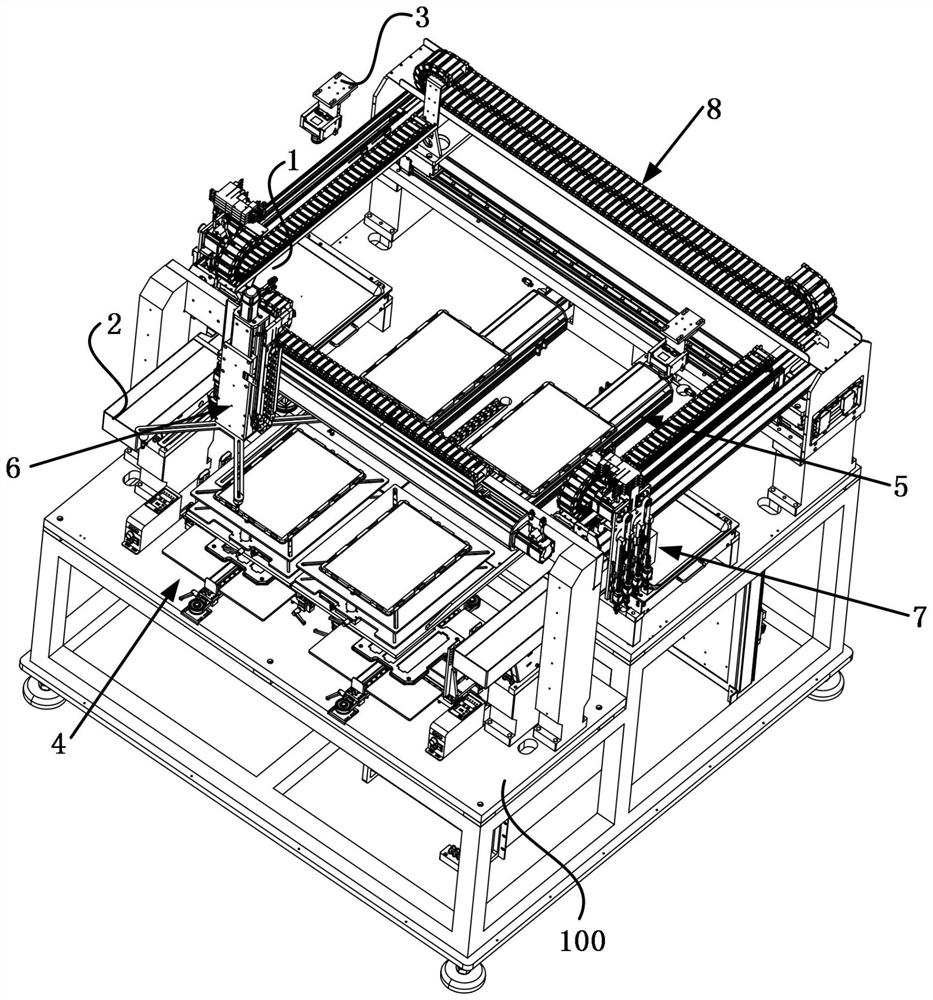

High-speed material presentation machine

It is a high-speed technology of a plate-setting machine, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., to achieve the effects of saving manpower and time, high degree of automation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

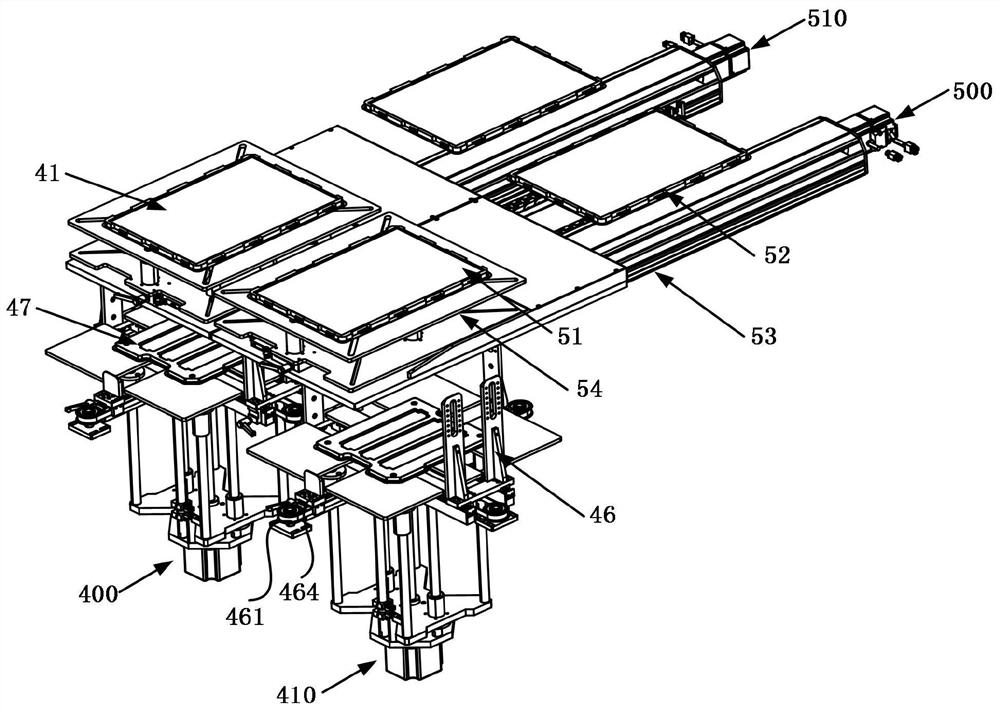

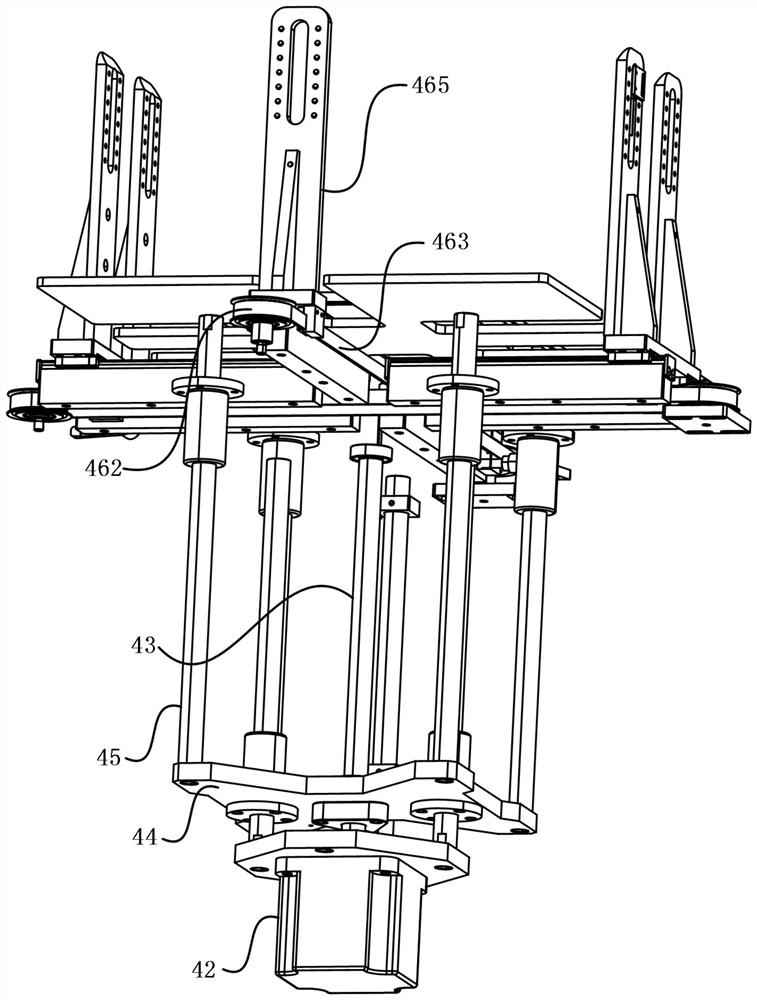

[0062] As an embodiment of the present invention, the material fetching mechanism 8 includes: a third suction mechanism 81, used to suck or loosen the material to be placed; a Z-axis linear motion module 82, used to drive and fix on it The third suction mechanism 81 moves along the Z-axis direction; the Y-axis linear motion module 83 is used to drive the Z-axis linear motion module 82 fixed thereon to move along the Y-axis direction; the X-axis linear motion module 84 is used to To drive the Y-axis linear motion module 83 fixed thereon to move along the X-axis direction. Here, the combination of the X-axis linear motion module 84 and the Y-axis linear motion module 83 enables the reclaiming mechanism 8 to perform reclaiming work in the entire plane composed of the X-axis and the Y-axis, which expands the reclaiming range and improves the working efficiency. efficiency.

[0063] Further, the X-axis linear motion module 84 is arranged along the X-axis direction, the X-axis line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com