Bulk material packaging process for automatically feeding, filling and sealing bag

A technology of bulk materials and packaging technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of transition bucket deviation, small opening, unreliable bag opening, etc., to achieve reliable opening of material bags, simple and reliable device structure, The effect of reducing the operating intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

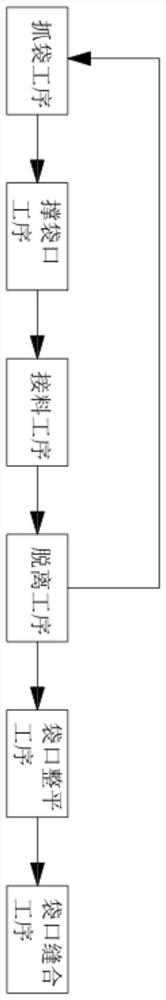

[0086] Such as figure 1 and figure 2 As shown, a packaging process for automatically bagging, filling and sealing bulk materials includes the following steps:

[0087] Step 1, the bag grabbing process, after the bag grabbing device 5 moves to the position directly opposite to the bag storage device 2, the bag grabbing assembly 52 descends to grab the material bag in the bag storage device 2;

[0088] Step 2, the bag opening process, after the grab bag assembly 52 is separated from the bag storage device 2 to grab the bag, the bag grab assembly 52 opens the bag mouth for standby;

[0089] Step 3, the material receiving process, the bag grabbing device 5 moves to directly below the discharge port of the filling machine 3, the bag grabbing assembly 52 rises to drive the material bag to cover the discharge port, and the filling machine 3 quantitatively discharges the material for filling, filling After completion, the bag grabbing device 5 falls vertically along the track, and ...

Embodiment 2

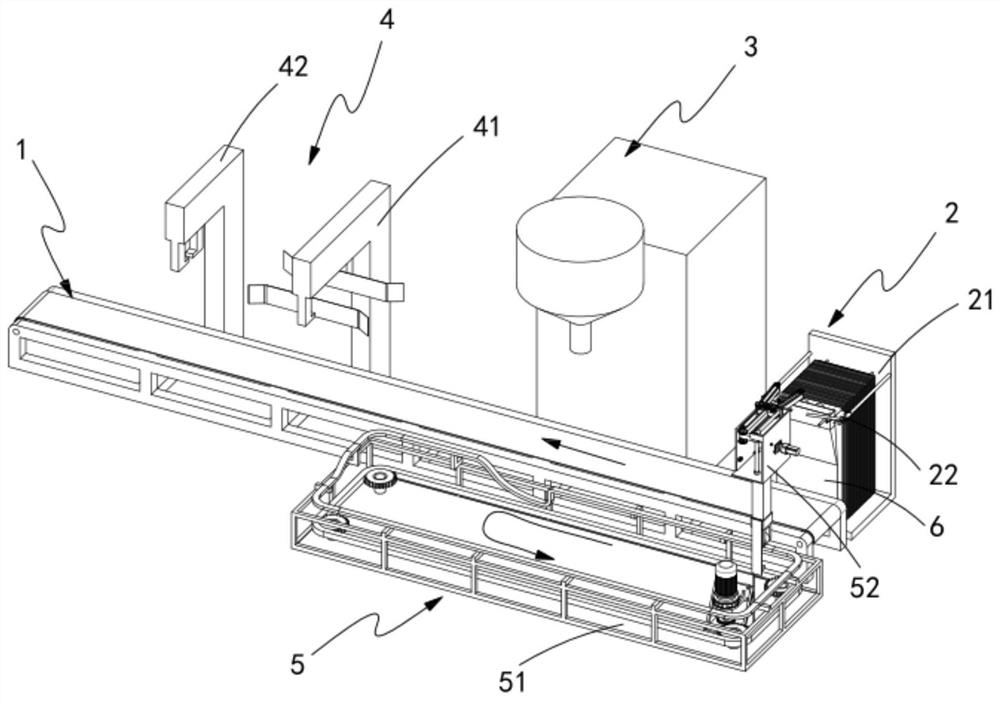

[0102] Such as Figure 2 to Figure 16 As shown, a packaging mechanism for automatically bagging, filling and sealing bulk materials includes a conveying mechanism 1, and a bag storage device 2, a filling machine 3 and a bag sealing device are arranged in sequence along the same side of the conveying direction of the conveying mechanism 1 The device 4 is provided with a bag grabbing device 5 on the other side of the conveying mechanism 1 relative to the bag storage device 2;

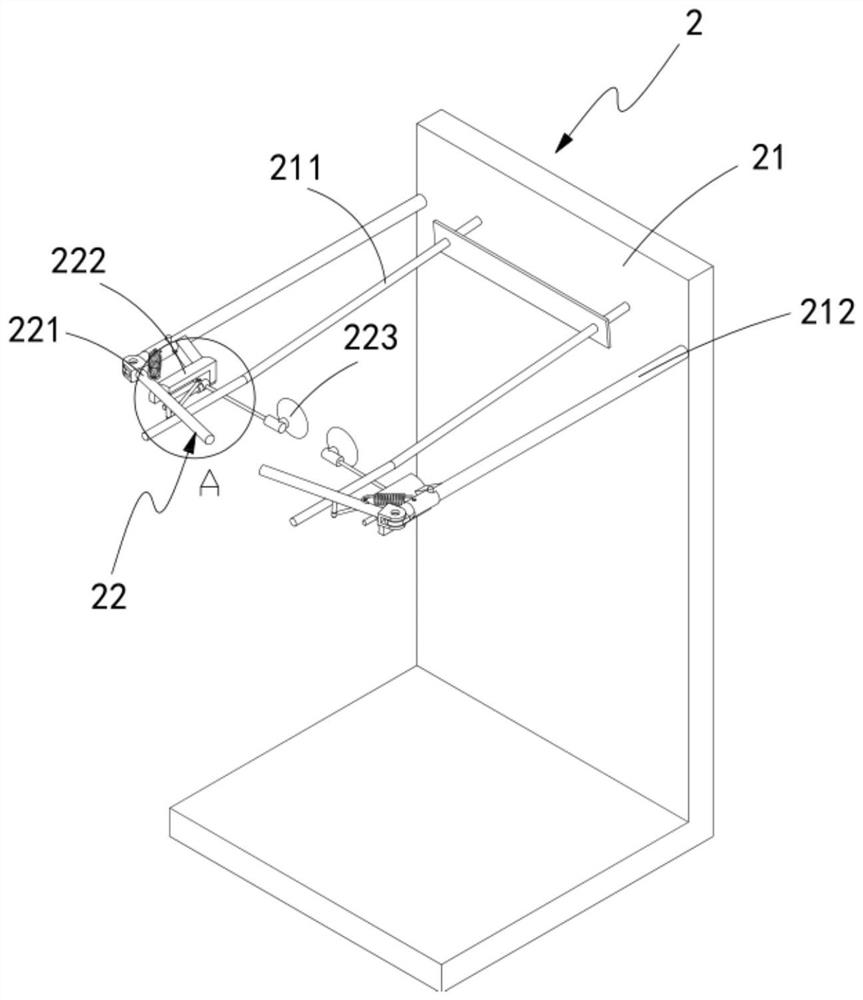

[0103] The bag storage device 2 includes a bag storage rack 21 and a bag opening mechanism 22, the bag storage rack 21 is provided with a bag support rod 211 and a bag opening support rod 212, the bag support rod 211 is arranged on the storage bag The upper part of the frame 21, and it is arranged facing the bag grabbing device 5, and a number of material bags 6 are stored on the material bag support rod 211, and the bag opening support rod 212 is arranged on the side of the material bag support rod 211. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com