Detachable convenient-to-transport rail flat car and using method

A transport track, dismantling technology, applied in the direction of transporting passenger cars, transport and packaging, railway car body parts, etc., can solve the problems of fast efficiency, ordinary rail flat cars can not meet the fast and convenient construction, short construction time, etc., to ensure parking. Safe, convenient for transit transportation, easy to install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

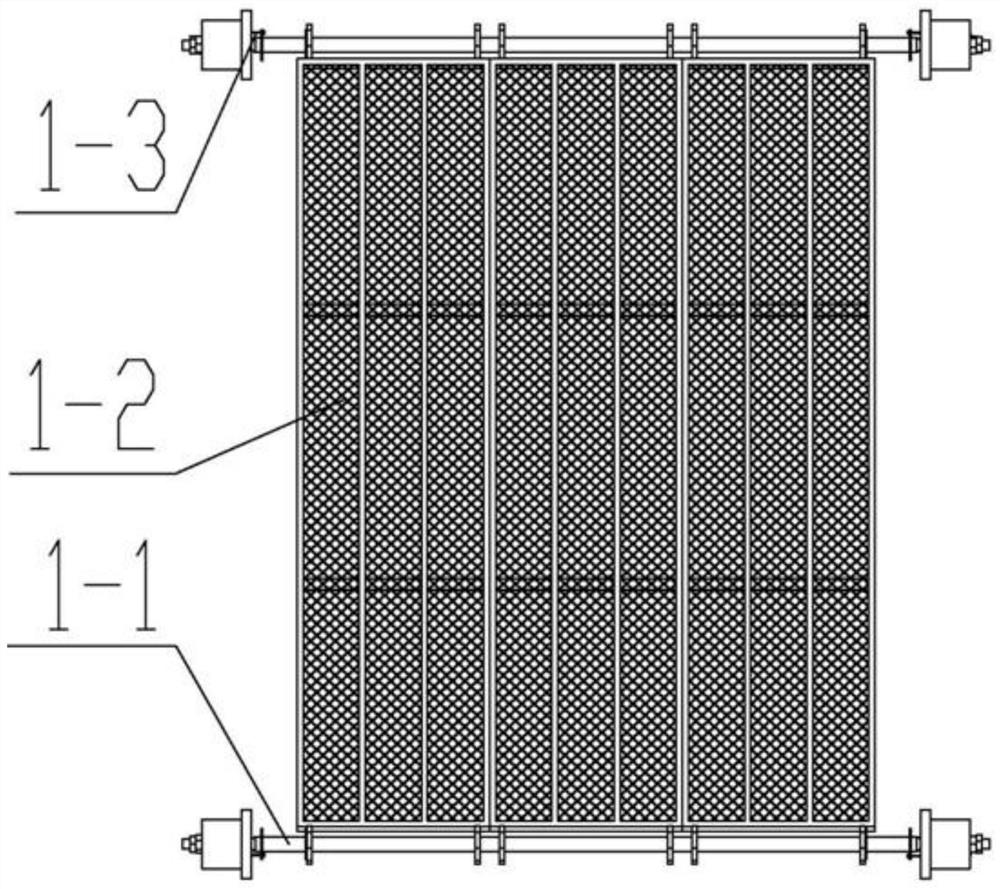

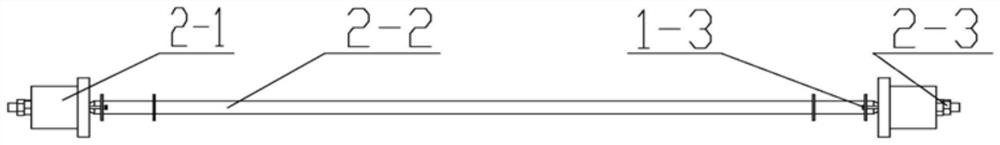

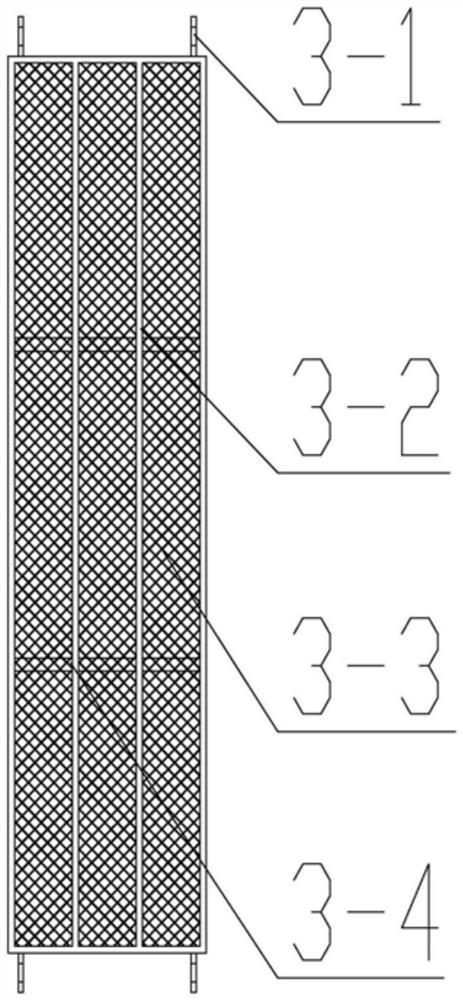

[0034] like Figure 7 As shown, a detachable convenient transport safety rail flat car described in this embodiment is mainly composed of a tripod, a wheel rail, a wheel axle, and an anti-slip safety pin, and the vehicle load is 1.5t. Each tripod is welded into a 390mm×1680mm frame by 4 longitudinal and 2 transverse channel steels with a thickness of 2mm. There is barbed wire on it and flat steel on the lower side. The whole vehicle platform is spliced by three tripods. , The steel wire mesh on the upper part of the tripod is used to carry and transport heavy objects, and the channel steel and flat steel play the role of fixing and supporting the tripod. The wheel rail is made of φ100mm insulating nylon material, the gauge is 1435mm, and there are several φ6mm slot holes on the inside of the wheel rail, which are used for inserting the anti-rolling safety pin to fix the wheel rail. There are baffles welded on both sides of the axle, which are used to fix the relative positi...

Embodiment 2

[0040]Before the work, the anti-slip safety pin was in a mating state with the wheel rail through the fixing hole on the anti-slip car safety pin fixed sheet, and now the wheel rail could not rotate freely relative to the axle. When working, first pull out the anti-slip safety pin, then place a pair of wheel sets on the standard track respectively, and then keep them at a certain position front and rear, and then put the three tripods into it respectively to ensure that the tripods are connected to the hooks. The hand and the axle are reliably connected and placed in the block to ensure that the relative position of the tripod is fixed.

[0041] Then push the detachable convenient transport rail flat car to the loading position, and then use the anti-slip safety pin to insert the anti-slip car safety pin fixing piece and the slot hole of the wheel rail to fix the flat car position to prevent it from moving during the loading process. cause an accident. Load the required trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com