An automatic calibration system for an analog remote control box and an automatic calibration method for an analog remote control box

An automatic calibration, remote control box technology, applied in the direction of instruments, measuring devices, measuring electrical variables, etc., can solve the problems of inconsistent display of the analog remote control box scale welding machine panel, inability to calibrate the zero point parameters of the remote control box, and inaccuracy, reducing manual Calibration time, saving after-sale costs, reducing the effect of output error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

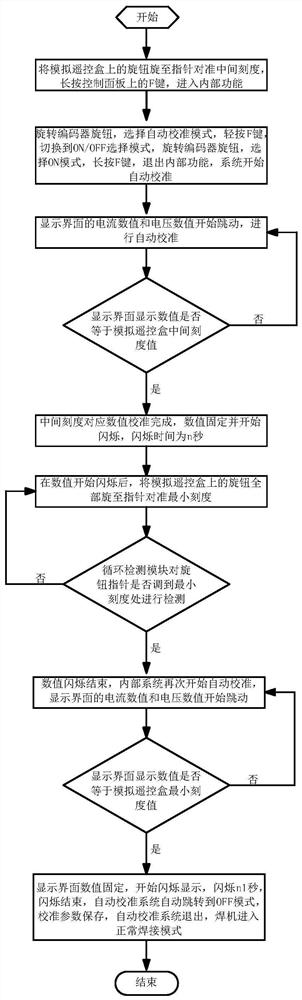

Embodiment 1

[0030] An automatic calibration system of an analog remote control box is installed in the internal function system of a welding power source. The control panel of the welding power source is provided with an internal function key F key, an encoder knob and a display interface, and the control panel is connected to the internal function system through a circuit. The automatic calibration system of the analog remote control box includes ON mode and OFF mode. The ON mode is the automatic calibration operation mode of the analog remote control box, including the output value adjustment module, the value comparison module, the fixed value flashing module and the cycle detection module; the OFF mode is the end of the automatic calibration mode, including the module of automatic saving of calibration parameters, the module of automatic shutdown of the calibration system and the module of entering normal welding mode. The automatic calibration method of the analog remote control box u...

Embodiment 2

[0038] An automatic calibration system for an analog remote control box, the system is installed in the internal function system of a welding power source, the control panel of the welding power source or the analog remote control box and the peripheral equipment connected to the welding machine are provided with a button M key, and the M key is directly connected through a circuit Automatic calibration system. The automatic calibration system of the analog remote control box includes ON mode and OFF mode. The ON mode is the automatic calibration operation mode of the analog remote control box, including the output value adjustment module, the value comparison module, the fixed value flashing module and the cycle detection module; the OFF mode is the end of the automatic calibration mode, including the module of automatic saving of calibration parameters, the module of automatic shutdown of the calibration system and the module of entering normal welding mode. The operation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com