Water draining system with gas double-wall pipe

A technology of drainage system and double-wall pipe, applied in the direction of pipeline system, pipe, rigid pipe, etc., can solve problems such as fire and gas discharge into the engine room, and achieve the effect of preventing gas from entering the engine room.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

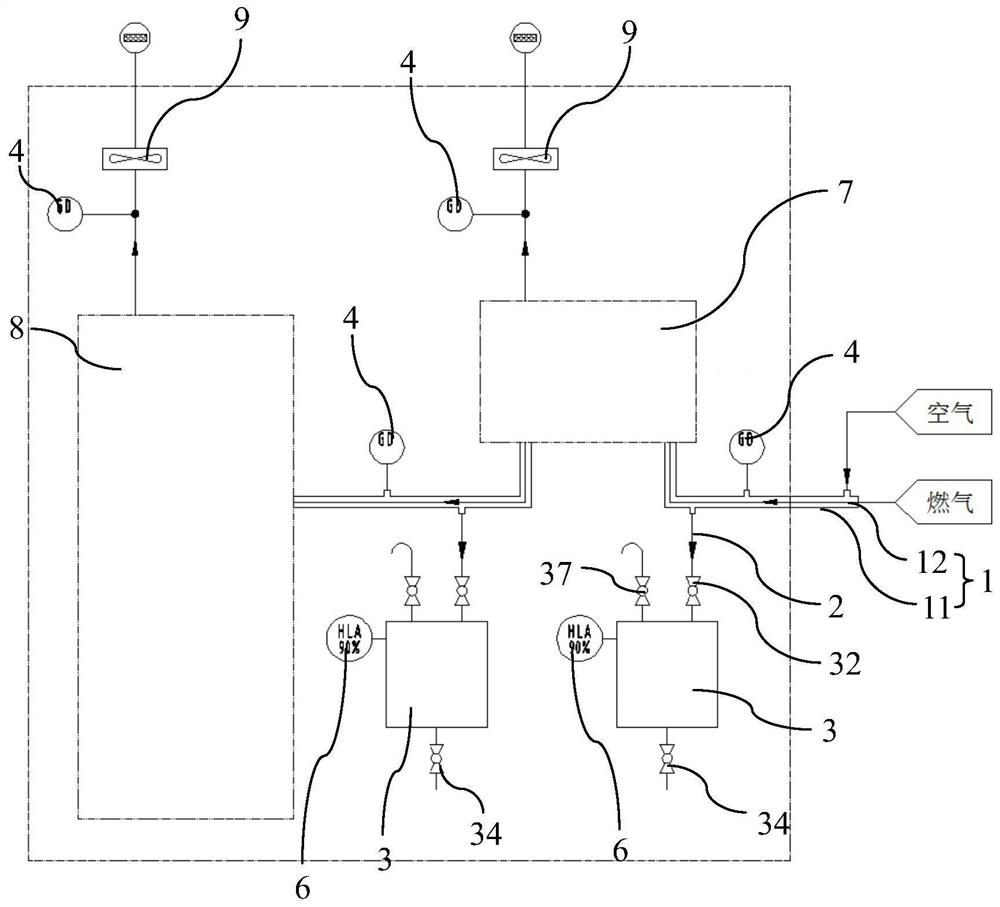

[0029] Such as Figure 1 to Figure 4 As shown, a gas double-wall pipe 1 drainage system described in the embodiment of the present invention includes a gas double-wall pipe 1, and a main engine gas valve group 7 and a The dual-fuel main engine 8, the air outlet of the main engine gas valve group 7, and the air outlet of the dual-fuel main engine 8 are all connected to the exhaust fan 9 through the ventilation pipe; the gas double-wall pipe 1 includes an outer pipe 11 and an inner pipe 12, and the inner pipe 12 The air inlet of the pipe 12 is connected to the gas inlet; a discharge pipe 2 is connected at the lowest point of each pipe body bend of the outer pipe 11; A combustible gas detection device 4 is provided on the connecting pipe section of the pipe 2;

[0030] A discharge pipe 2, the water outlet of the discharge pipe 2 is connected to the water inlet 31 of the discharge tank 3;

[0031] The discharge tank 3, the water inlet 31 of the discharge tank 3 is equipped with ...

Embodiment 2

[0042] Such as Figure 5 As shown, the difference between the gas double-wall pipe 1 drainage system provided in this embodiment and the first embodiment is that the number of the discharge tank 3 is one, and the water outlet of each discharge pipe 2 is connected to the Describe the water inlet 31 of the discharge tank 3.

[0043] To sum up, the drainage system of the gas double-wall pipe 1 according to the present invention can be kept open by controlling the first stop valve 32, so that the condensed water in the outer pipe 11 can be directly discharged into the discharge tank 3, In this way, the condensed water avoids blocking the outer pipe 11; in addition, before opening the second shut-off valve 34 to discharge the condensed water in the drain tank 3 to the engine room sewage well, first confirm whether the combustible gas detection device 4 is Trigger an alarm response, if an alarm response occurs, then first close the air inlet of the inner pipe 12, and simultaneously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com