Filling material containing lepidolite slag as well as preparation method and application thereof

A technology of filling material and lepidolite, which is applied in application, filling, mining equipment, etc., can solve the problems of further improvement of final setting strength, inconvenient subsequent mining of filling construction, and reduced mechanical properties of materials, so as to achieve excellent compactness and fast The effect of large initial setting time and foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

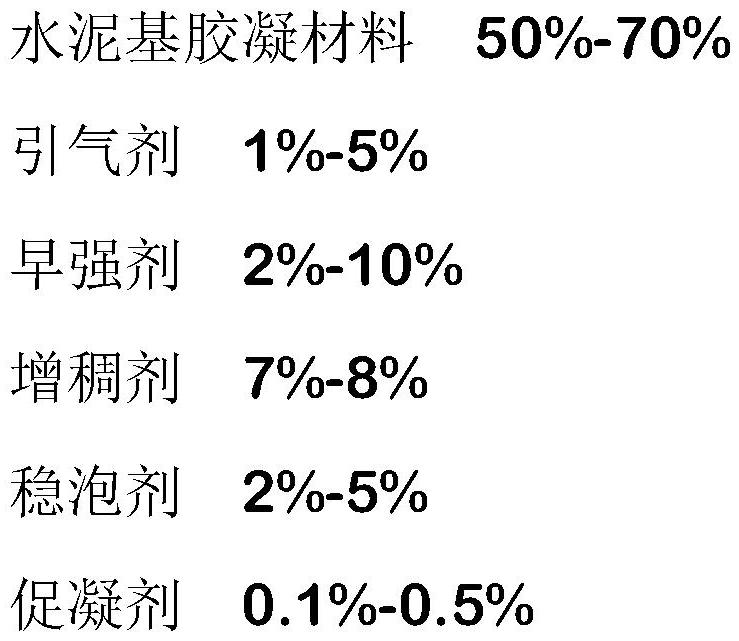

[0028] According to the mass parts of cement-based cementitious materials, lepidolite slag, air-entraining agent, early strength agent, thickener, foam stabilizer and coagulant listed in Table 1 below, the lepidolite slag-based high The water filling material is ready for use.

[0029] Table 1

[0030]

[0031] The lepidolite slag-based high-water filling material prepared in Table 1 is mixed with water in the mixing chamber of the grouting pump according to the mass ratio listed in Table 2 below, and the product performance indicators are listed in Table 2.

[0032] Table 2

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com