Tile fast collecting device

A kind of collection equipment and fast technology, applied in the direction of shock-sensitive items, packaging, packaging item types, etc., can solve the problems of low work efficiency and manpower consumption, and achieve the effect of improving work efficiency, simple operation and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

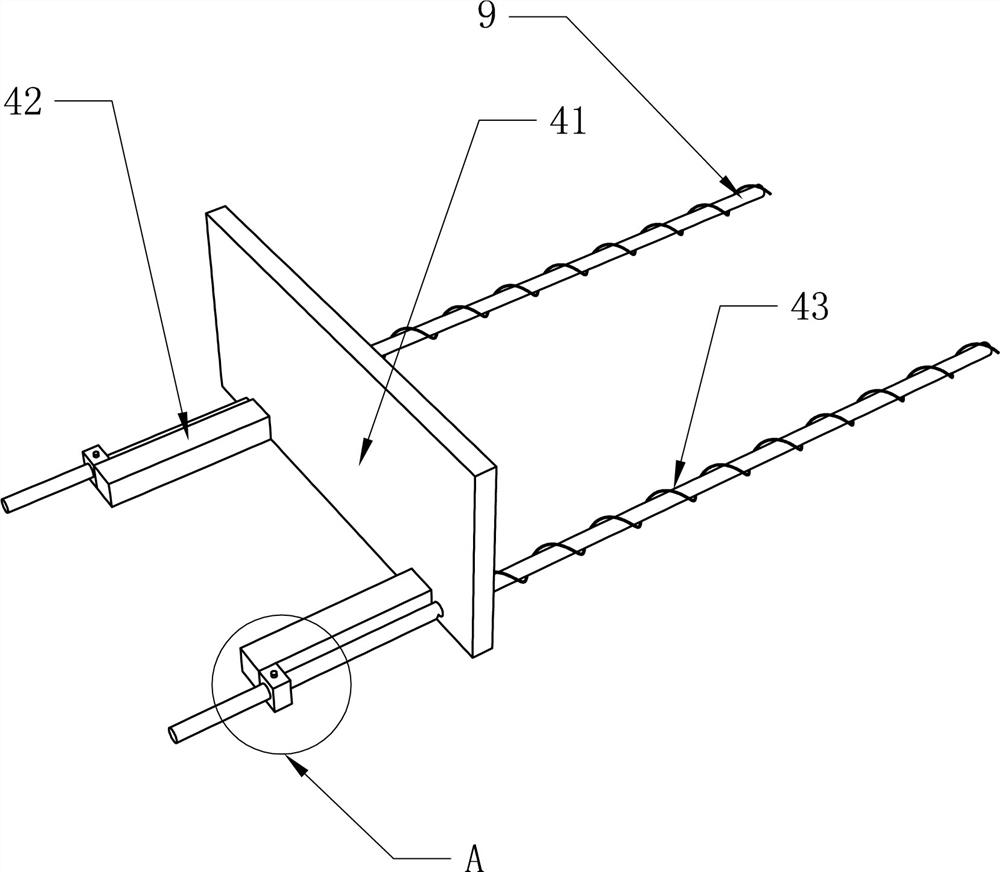

[0027] A quick collection device for tiles such as Figure 1-5 As shown, it includes a frame 1, a transmission assembly 2, a collection assembly 3, a handling assembly 4, a conveying roller 8 and an inclined cylindrical track 9, and the front side of the frame 1 is connected with two inclined cylindrical tracks 9, and the inclined cylindrical track 9 is Inclined setting, the right side of the frame 1 is uniformly spaced and rotationally connected with multiple conveying rollers 8, the conveying rollers 8 are located on the rear side of the inclined cylindrical track 9, and the conveying component 2 and the collecting component 3 are arranged on the frame 1, and the frame 1 A handling assembly 4 is arranged between the inclined cylindrical track 9 .

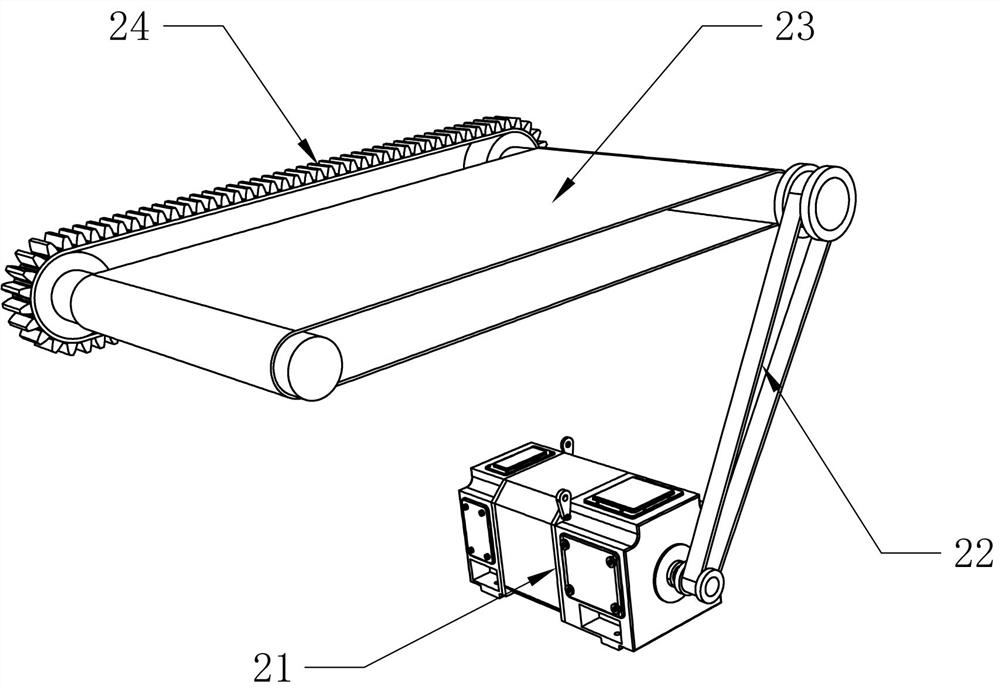

[0028] The transmission assembly 2 includes a motor 21, a first belt 22, a conveyor belt 23 and a timing belt 24, a motor 21 is installed in the middle of the frame 1, a conveyor belt 23 is rotatably connected to the upper left si...

Embodiment 2

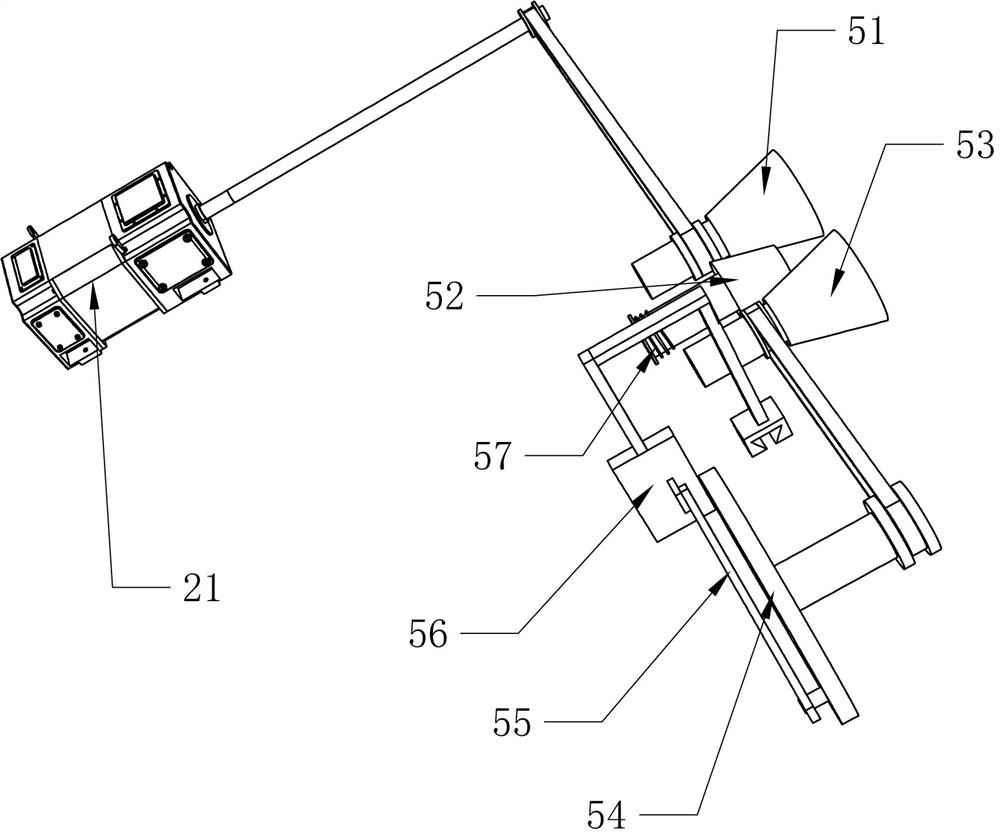

[0033] On the basis of Example 1, such as Image 6As shown, a push assembly 5 is also included, and the push assembly 5 includes a driving rubber 51, an intermediate transmission rubber 52, an output rubber 53, a circular plate 54, a push rod 55, a push plate 56 and a third return spring 57. The right side is rotationally connected with a driving rubber 51, the driving rubber 51 is connected with the output shaft of the motor 21 through a belt and a pulley, and the outer right side of the frame 1 is slidingly connected with an intermediate transmission rubber 52, and the intermediate transmission rubber 52 rotates with the frame 1 Cooperate, the third return spring 57 is connected between the intermediate transmission rubber 52 and the frame 1, the third return spring 57 is rotatably matched with the intermediate transmission rubber 52, the intermediate transmission rubber 52 is located at the front side of the driving rubber 51 and will be in contact with the driving rubber 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com