Oil and gas pipeline station yard design method based on safety life cycle

A design method and life cycle technology, applied in the field of oil and gas pipeline station design based on the safety life cycle, can solve problems such as contradictions, mutual influence of construction or maintenance work, and inability to plan and design pipeline maintenance and maintenance periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

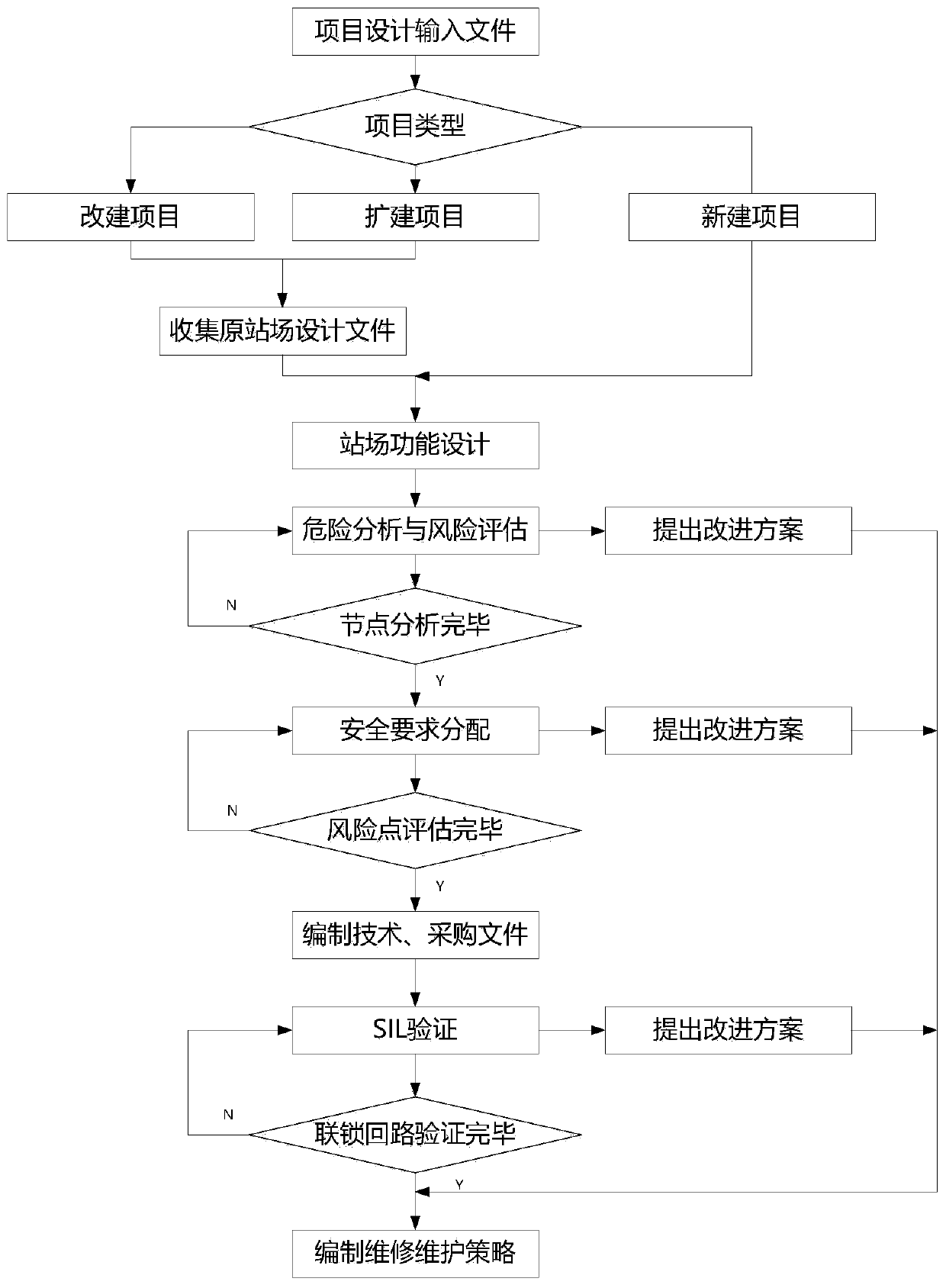

[0022] Such as figure 1 As shown, what is described in the embodiment of the present invention is a method for designing an oil and gas pipeline station based on a safety life cycle, and the method includes:

[0023] Step 1. Collect the basic information required for project design according to the project type;

[0024] Step 2. According to the requirements of the basic data in step 1, design the process flow, auxiliary flow and auxiliary facilities of the oil and gas pipeline station. According to the station design input data requirements, carry out the design work of station technological process, auxiliary process and auxiliary facilities, and record and file the design results.

[0025] Step 3. According to the design documents in step 2, carry out hazard analysis and risk assessment of oil and gas pipeline stations; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com