Wind tunnel test equipment for wind-induced particulate matter drifting

A wind tunnel test and particulate matter technology, used in aerodynamic tests, machine/structural component testing, measuring devices, etc., can solve the problems of high blocking ratio, large volume, labor and material resources, etc., and achieve a small impact on wind profile, The effect of small windward surface and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

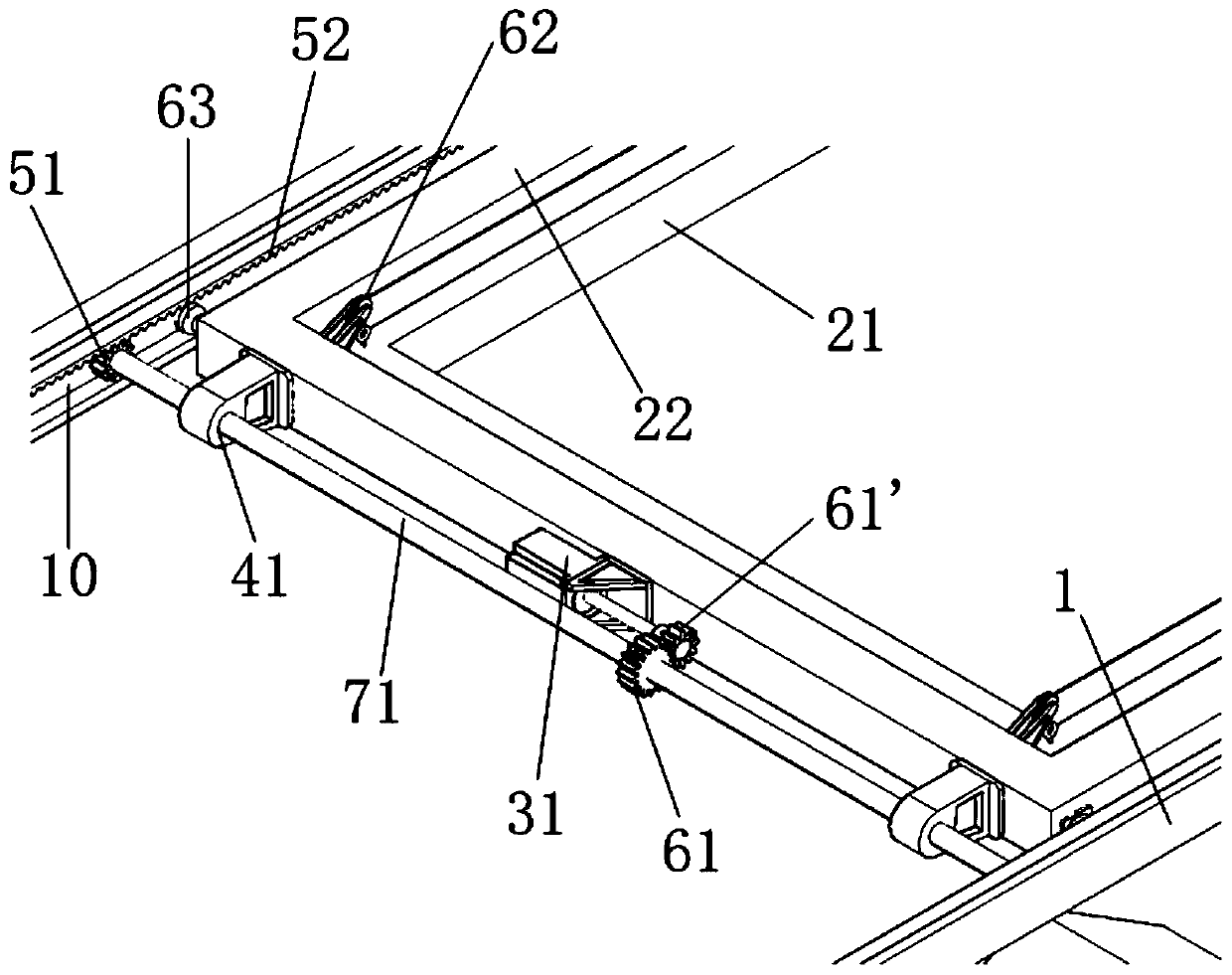

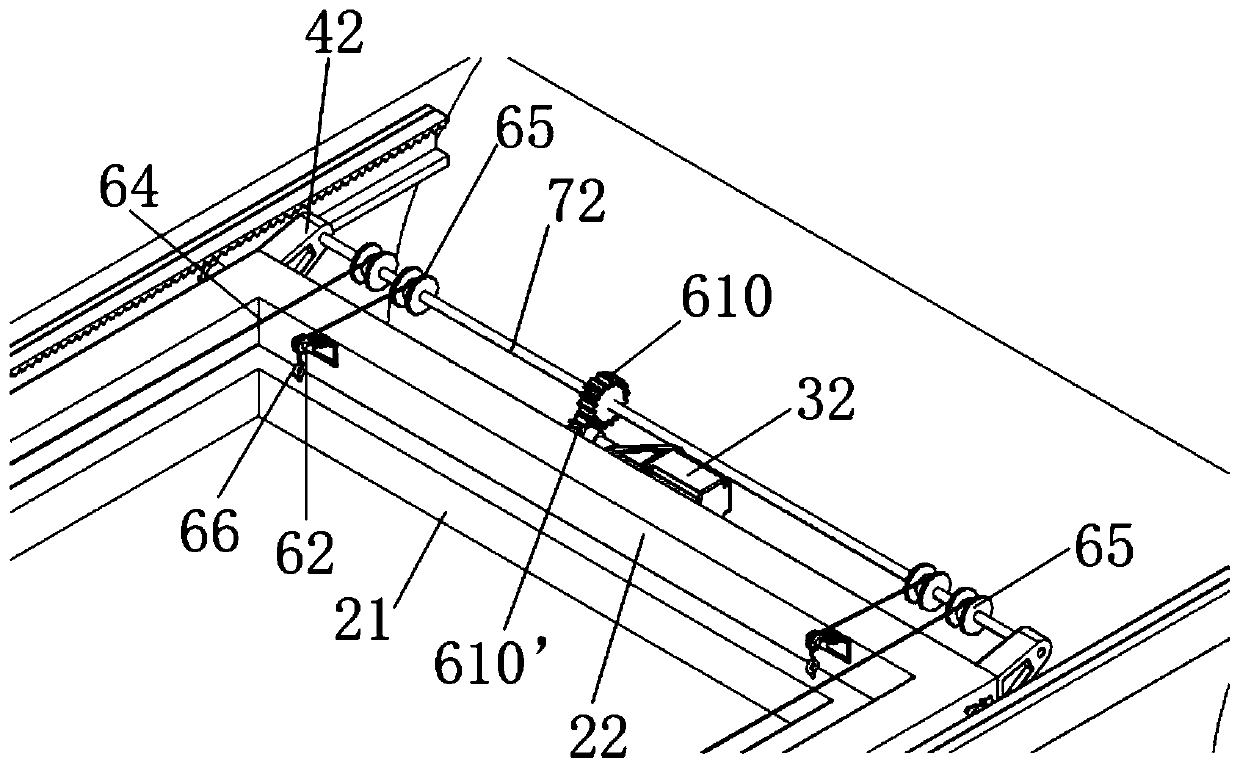

[0032] Exemplary embodiments of the present disclosure are described below with reference to the accompanying drawings. It should be understood that these specific descriptions are only used to teach those skilled in the art how to implement the present disclosure, but are not intended to exhaust all possible ways of the present disclosure, nor are they used to limit the scope of the present disclosure.

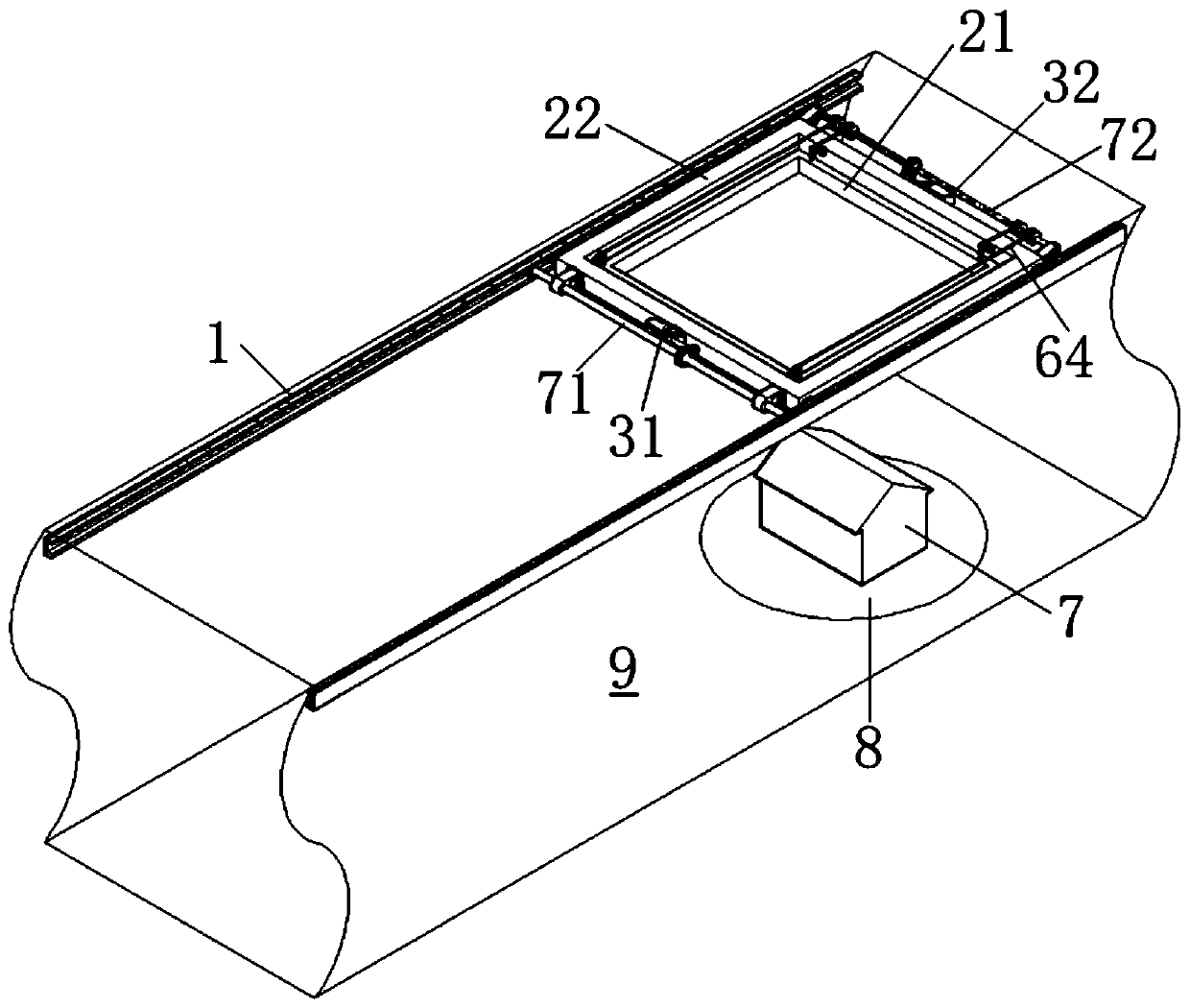

[0033] Such as Figure 1 to Figure 3 As shown, the present disclosure provides a wind tunnel test device for wind-induced particle drift (hereinafter referred to as "wind tunnel test device"), which includes a screen assembly, a drive assembly, a lifting assembly and a track 1 . The wind tunnel test equipment can be used in conjunction with the target building 7 and the turntable 8 , the turntable 8 can rotate 360 degrees, and the target building 7 is arranged on the turntable 8 and can rotate together with the turntable 8 .

[0034] The wind tunnel test section includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com