Automobile oil pump shell

An oil pump and casing technology, applied in the field of automobile oil pump casings, can solve the problems of shaking and misalignment of the upper casing and the lower casing, the position deviation of screwing bolts, and the cumbersome screwing process, etc., so as to facilitate assembly and improve the The effect of sealing and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

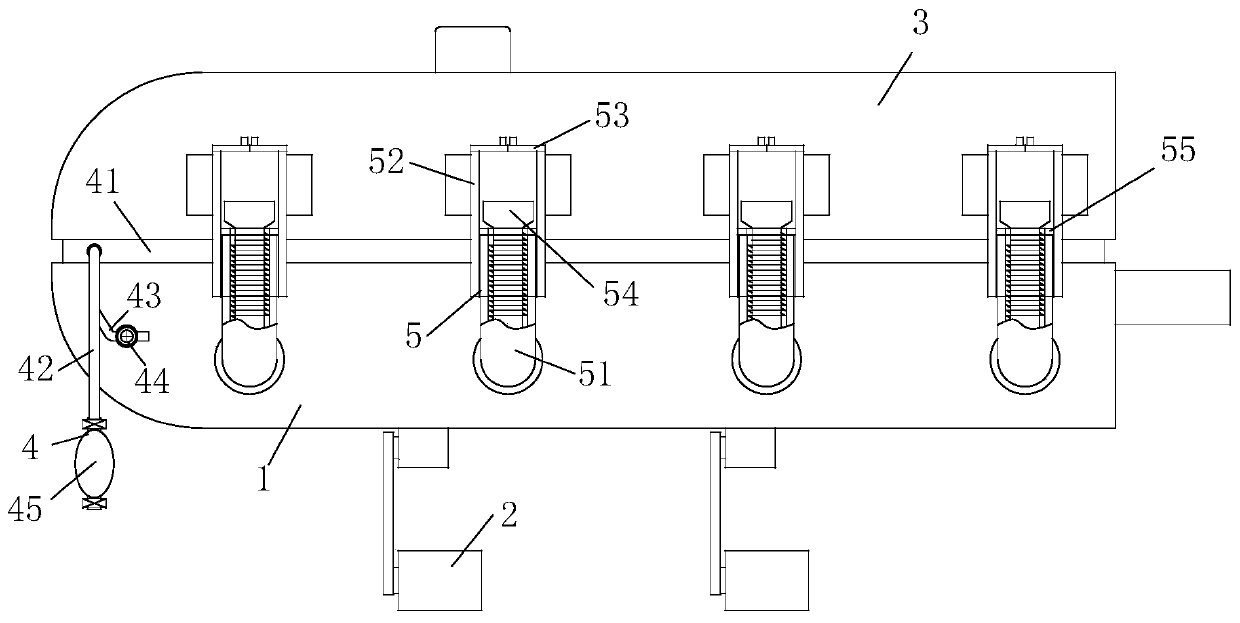

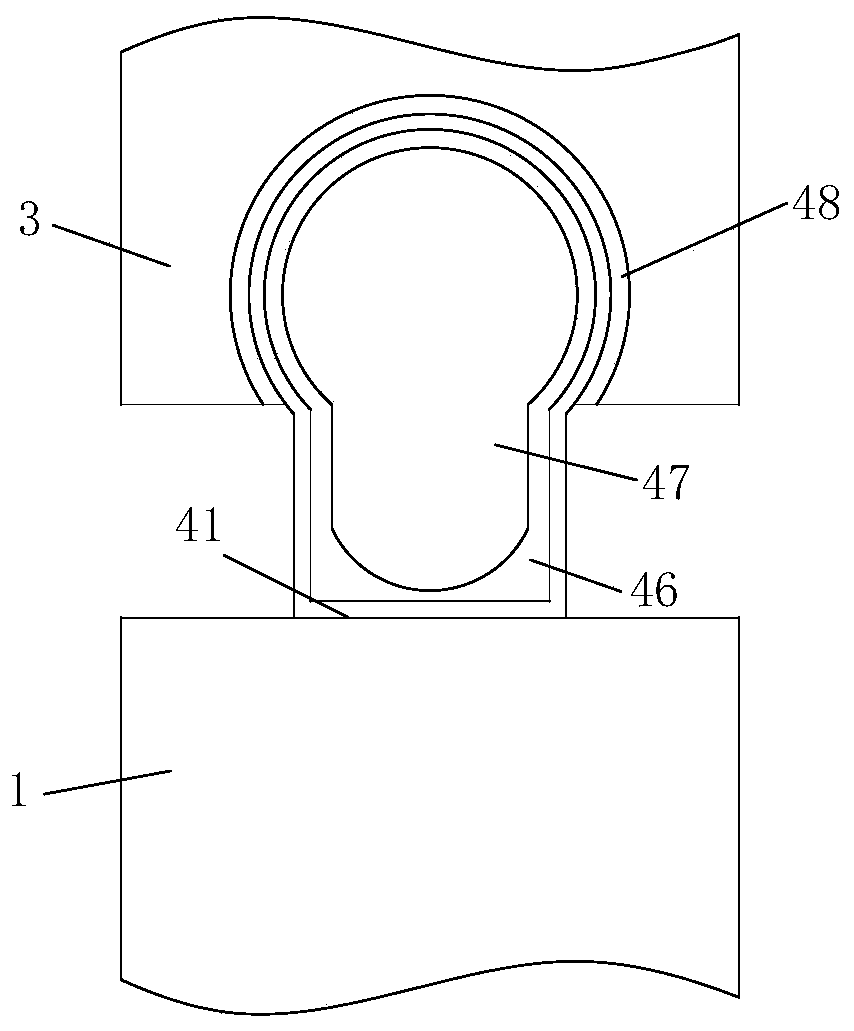

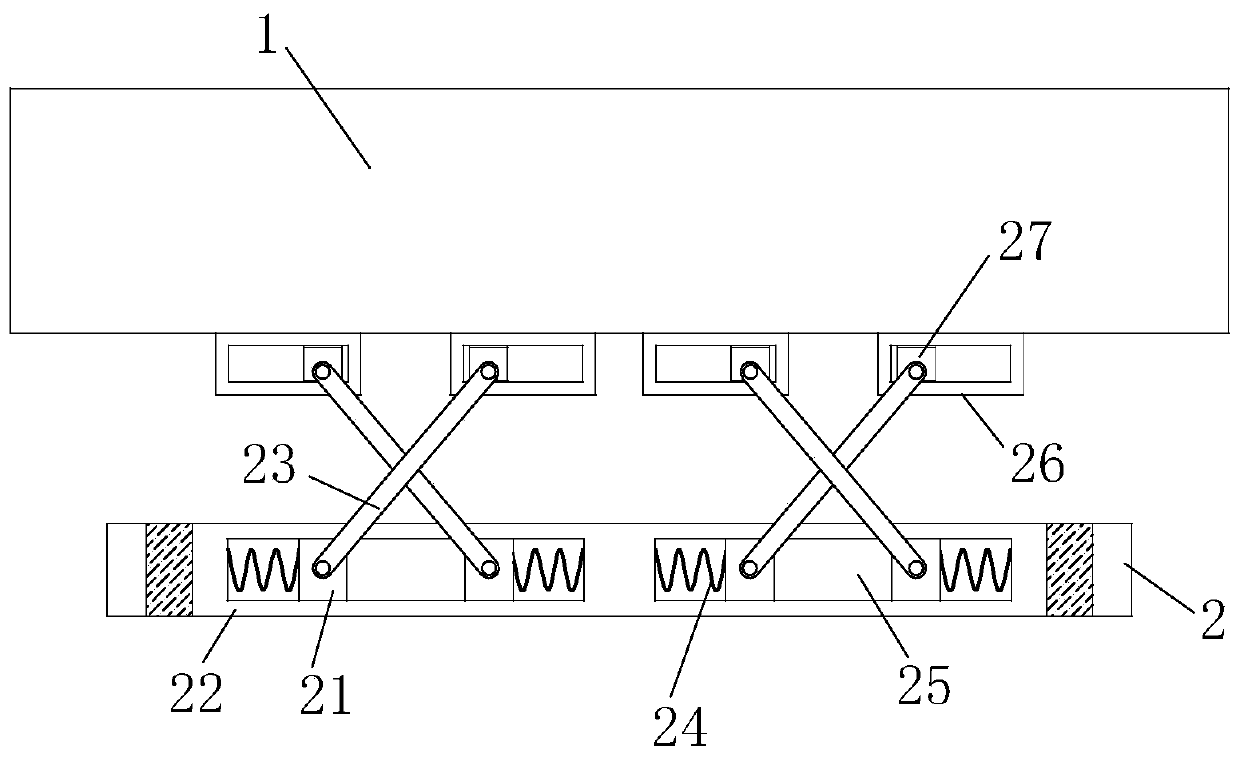

[0019] Please refer to figure 1 , figure 2 and image 3 , an automobile oil pump housing, comprising a lower housing 1, a shock absorbing support structure 2, an upper housing 3, a pre-clamping structure 4 and a positioning installation structure 5, the pre-clamping structure 4 is connected to the lower housing 1 1. At the side wall where the upper shell 3 fits, the pre-clamping structure 4 includes a pre-clamping sealing ring 41, an air intake pipe 42, an exhaust pipe 43, a valve 44, an air bag 45 and a clamping air bag 47, and the lower shell 1 The bottom side wall is connected with the pre-clamping sealing ring 41, and the inside of the pre-clamping sealing ring 41 is provided with a volume cavity 46, and the clamping air bag 47 is arranged inside the volume cavity 46. It runs through the pre-clamping sealing ring 41 and communicates with the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com