Coalbed methane staged fracturing horizontal well productivity simulation test device and method

A staged fracturing and simulation testing technology, which is applied to earthwork drilling, wellbore/well components, production fluids, etc., can solve problems such as inaccurate reflection of objective facts, less than 1 millidarcy, and order of magnitude differences, and achieve Improve design, improve work efficiency, and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

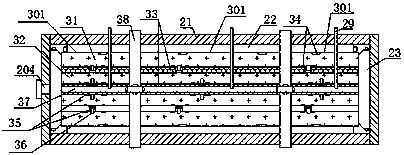

[0024] Such as figure 1 and 2 As shown, a coalbed methane staged fracturing horizontal well productivity simulation test device includes a bearing platform 1, a dynamic loading mechanism 2, a coal reservoir simulation mechanism 3, a gas recovery mechanism 4 and a data acquisition device 5, wherein the bearing platform 1 includes Carrying frame 101, operating table 102 and console 103, wherein carrying frame 101 is a frame structure whose axis is perpendicular to the horizontal plane, its upper end surface is connected with operating table 102 and coaxially distributed, and the side surface is mutually connected with at least one console 103 connection, the coal reservoir simulation mechanism 3 is connected to the workbench 102 through at least three positioning fixtures 7, the axis of which is distributed parallel to the horizontal plane, the power loading mechanism 2, the gas recovery mechanism 4 and the data acquisition device 5 are all connected to the carrying frame 101, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com