Self-adaptive adjustable tramcar track cleaning device

An adaptive adjustment, tram track technology, applied in track cleaning, cleaning methods, construction, etc., can solve the problems of inability to automatically use track width, different tram track specifications, troublesome use process, etc., to achieve high use efficiency, increase Clean area, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

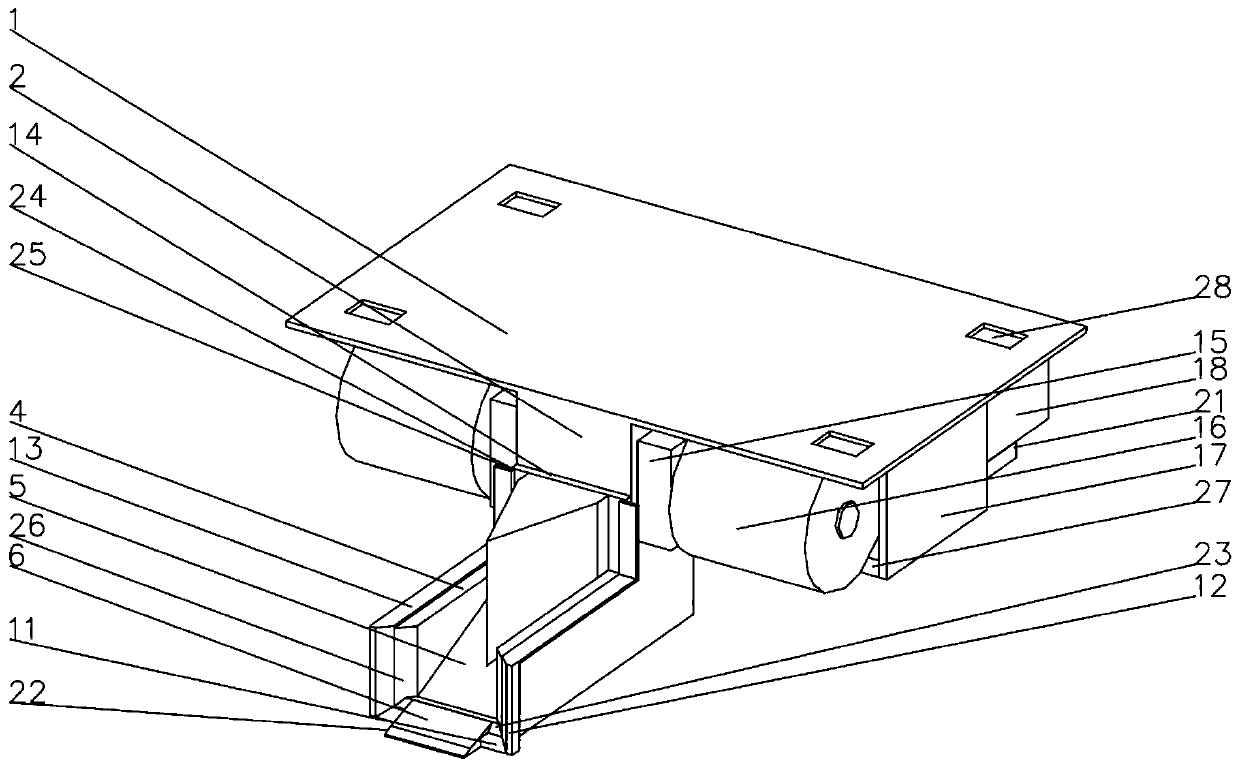

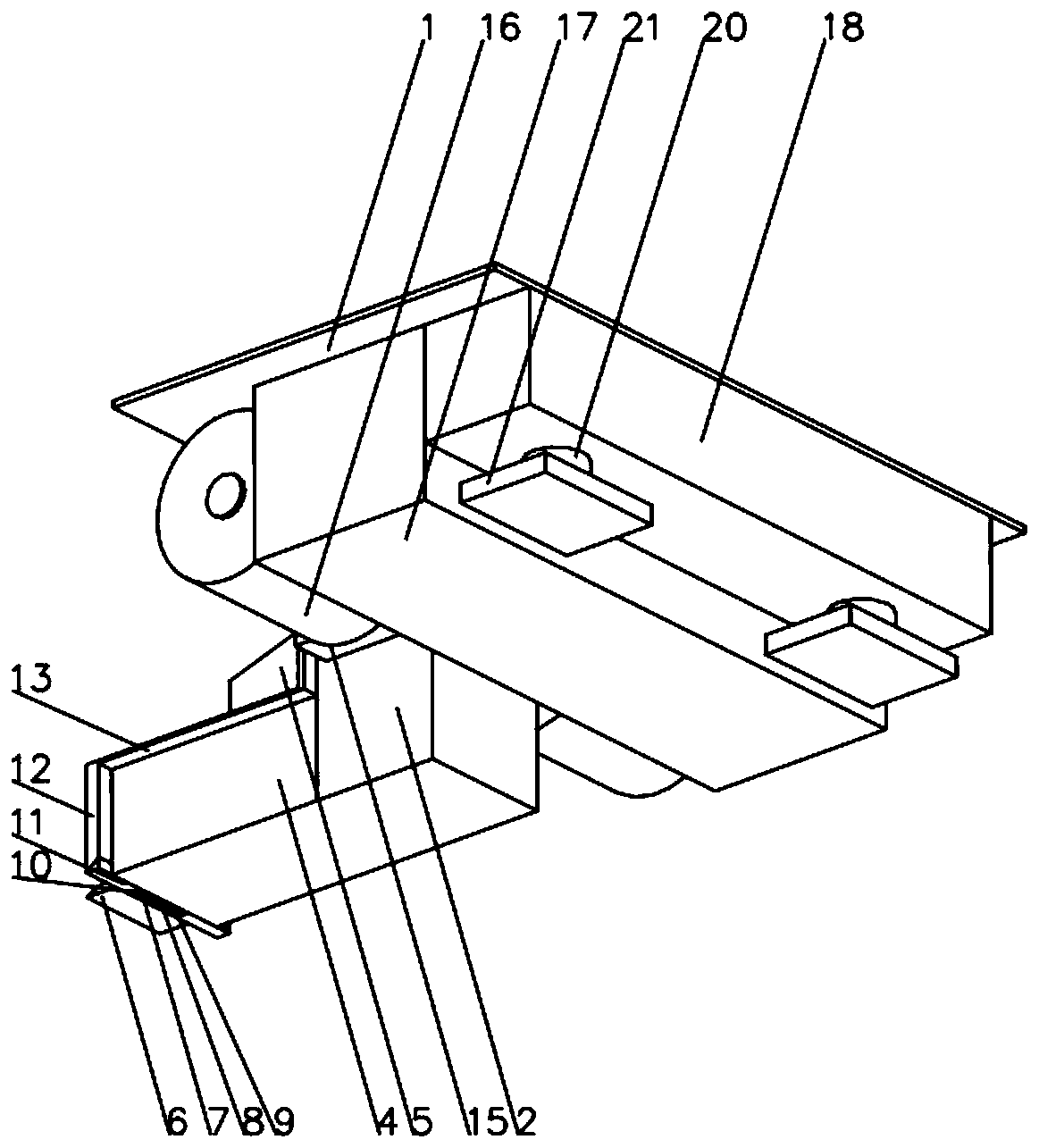

[0033] see Figure 1-4, the present invention provides a technical solution: a self-adaptive adjustable tram track cleaning device, comprising a positioning plate 1, a fixing frame 2 is fixedly connected to the bottom of the positioning plate 1, a guide frame 4 is fixedly connected to one side of the fixing frame 2, and a guiding frame 4 is fixedly connected to the bottom of the positioning plate 1. The bottom of the inner wall of the frame 4 is fixedly connected with a guide cone 5, and the bottom of the end of the guide frame 4 away from the fixed frame 2 is fixedly connected with a shovel plate 6, and the garbage entering the guide frame 4 through the shovel plate is shunted through the guide cone 5, and the waste in the guide frame 4 is shunted. Garbage is diverted to both sides of the guide frame, the bottom of the shovel plate 6 is provided with a storage tank 7, the center of the inner wall of the storage tank 7 is fixedly connected to a top plate 8, both sides of the to...

Embodiment 2

[0035] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: an adaptively adjustable tram track cleaning device, comprising a positioning plate 1, the bottom of the positioning plate 1 is fixedly connected with a fixing frame 2, and the inside of the fixing frame 2 is fixedly connected There is a double-axis motor 15, and the drive shafts on both sides of the double-axis motor 15 are fixedly connected with a cleaning broom 16, and the side of the fixed frame 2 away from the guide frame 4 is fixedly connected with a storage box 17, and the side of the storage box 17 away from the fixed frame 2 A dust storage box 18 is fixedly connected, and a dust suction device 19 is fixedly connected to the bottom of the inner wall of the dust storage box 18. The dust collector 21, the garbage on the ground is first cleaned by the cleaning broom 16, and the larger garbage is swept into the storage box 17, and the remaining smaller garbage and du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com