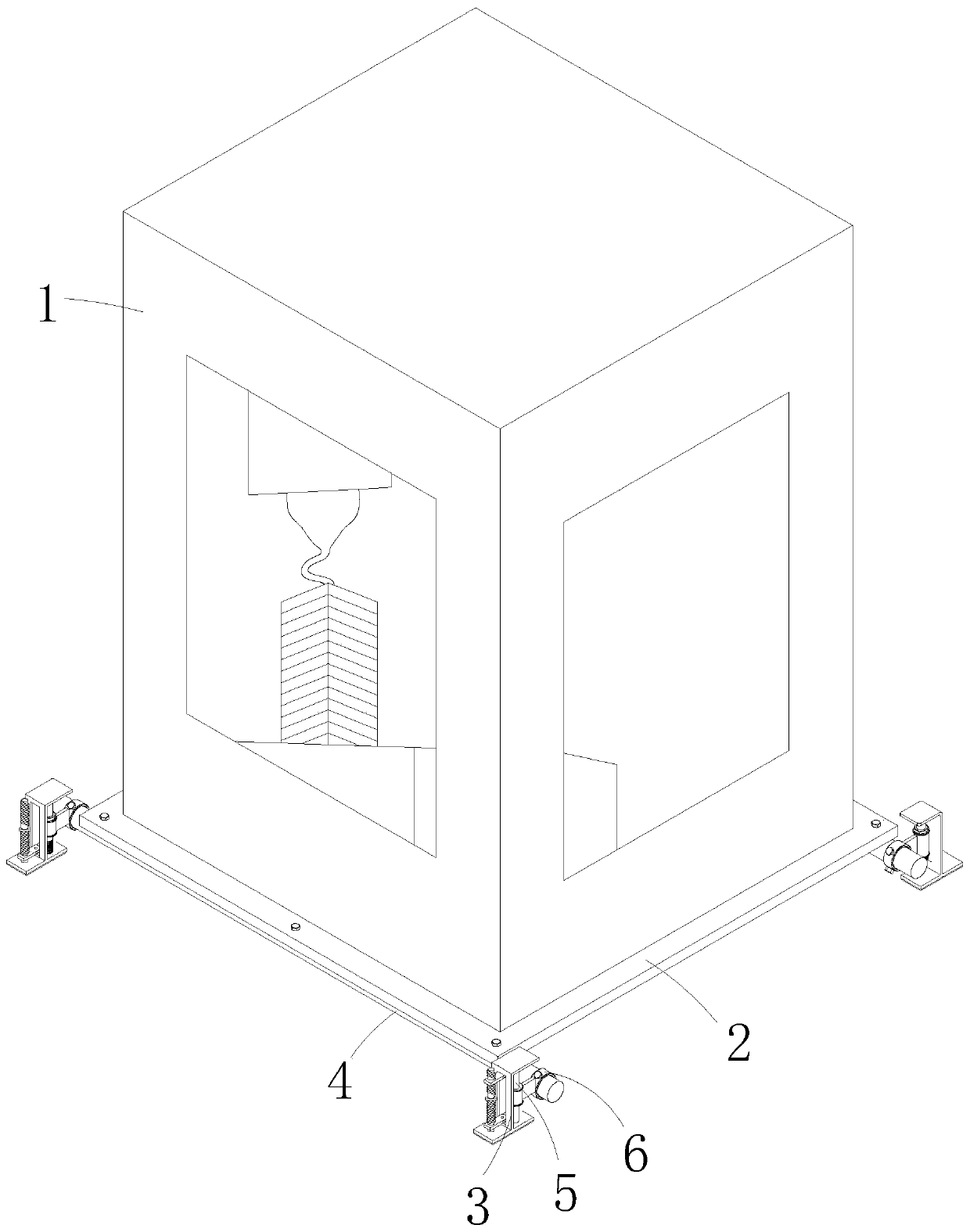

3D printing machine with data collection and storage functions

A 3D printer, storage function technology, applied in mechanical equipment, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problem of inability to adjust the vibration frequency and amplitude, printing accuracy and noise reduction buffer level of 3D printers according to actual use conditions. Adaptive adjustment, vibration of the body, etc., to improve the printing effect, improve the service life, and reduce the friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

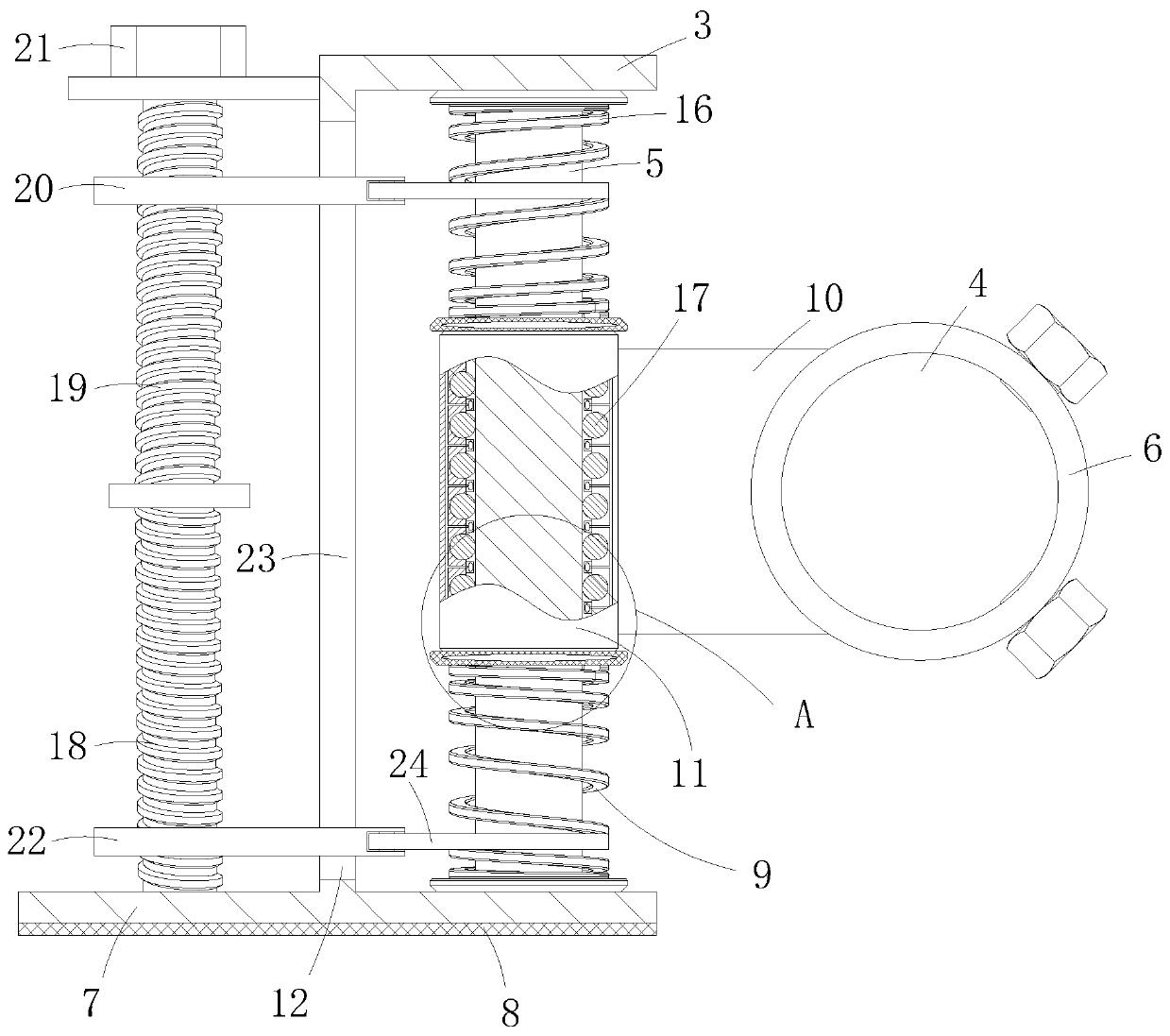

[0025] As an embodiment of the present invention, the upper surface of the flat bottom 7 of the support member 3 is rotatably connected with a first screw 18; the first screw 18 is arranged opposite to the sliding post 5; the upper end of the first screw 18 is fixedly connected There is a connecting block; the upper surface of the connecting block is fixedly connected with a second screw 19; the screw thread of the second screw 19 is opposite to that of the first screw 18; the upper end of the second screw 19 is rotatably connected with a fixed plate 20; The fixing plate 20 is fixedly connected to the surface of the L-shaped part 12 of the support member 3; the second screw rod 19 is set through the fixing plate 20, and the surface of one end of the second screw rod 19 passing through the fixing plate 20 is fixedly sleeved with a knob 21; Both the surface of the first screw 18 and the second screw 19 are threaded with a sliding plate 22; the surface of the L-shaped portion 12 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com