An automatic focusing high-efficiency laser cutting device

A technology of laser cutting and automatic focusing, applied in laser welding equipment, metal processing equipment, welding equipment, etc., it can solve the problems of deep and shallow cutting, the laser power cannot be adjusted at any time, and the cutting quality is affected, and the operation is convenient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

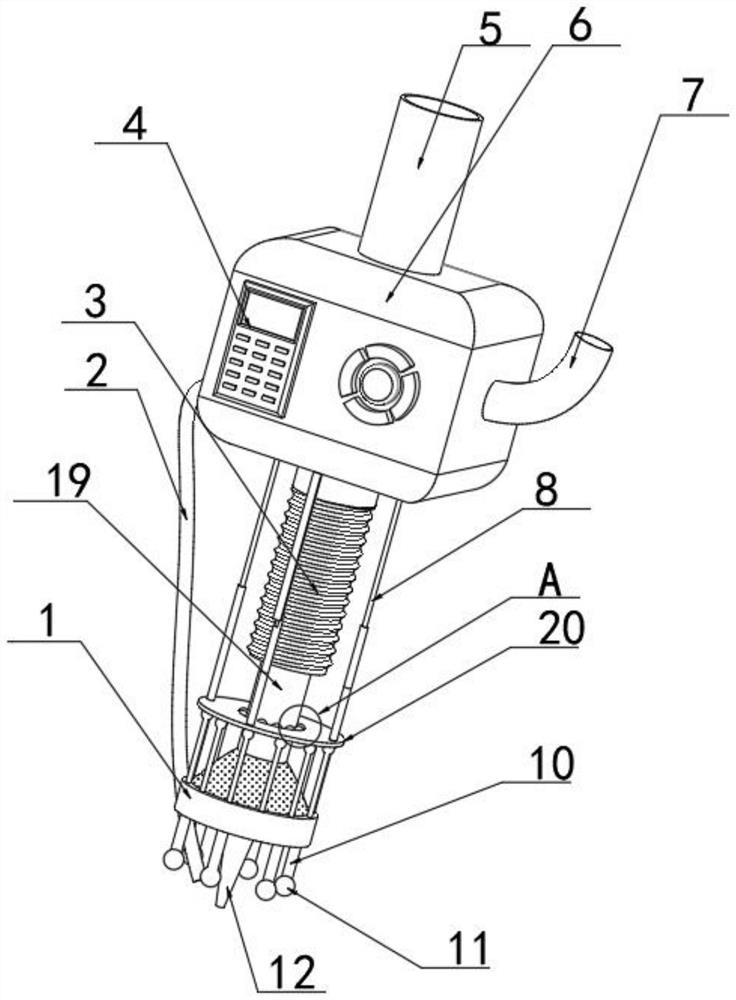

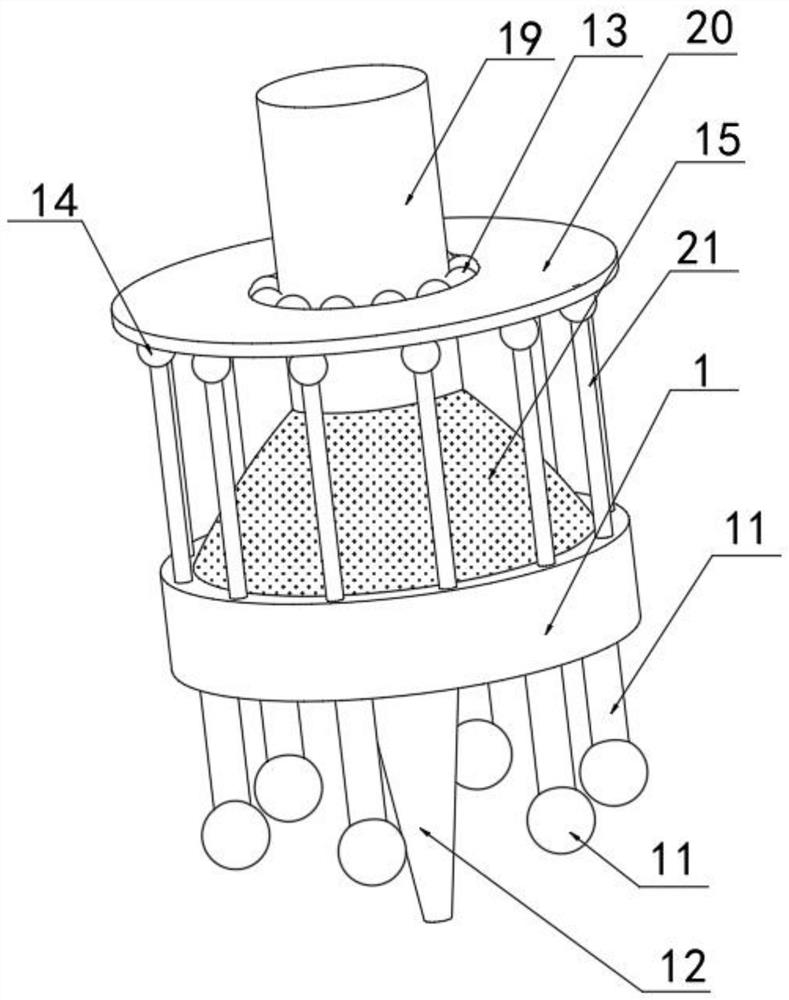

[0027] An embodiment of the present invention provides an automatic focusing high-efficiency laser cutting device, such as Figure 1-6 As shown, it includes a housing 6, the top of the housing 6 is fixedly connected with a laser transmission device 5, the bottom of the laser transmission device 5 extends out of the bottom of the housing 6, the bottom of the laser transmission device 5 is fixedly connected with a telescopic hose 3, and the bottom of the telescopic hose 3 The laser connection device 19 is fixedly connected, the bottom of the laser connection device 19 is fixedly connected with the cutting head 12, the outside of the laser connection device 19 is fixed with an adjustment mechanism, and one side of the housing 6 is fixed with a cleaning assembly;

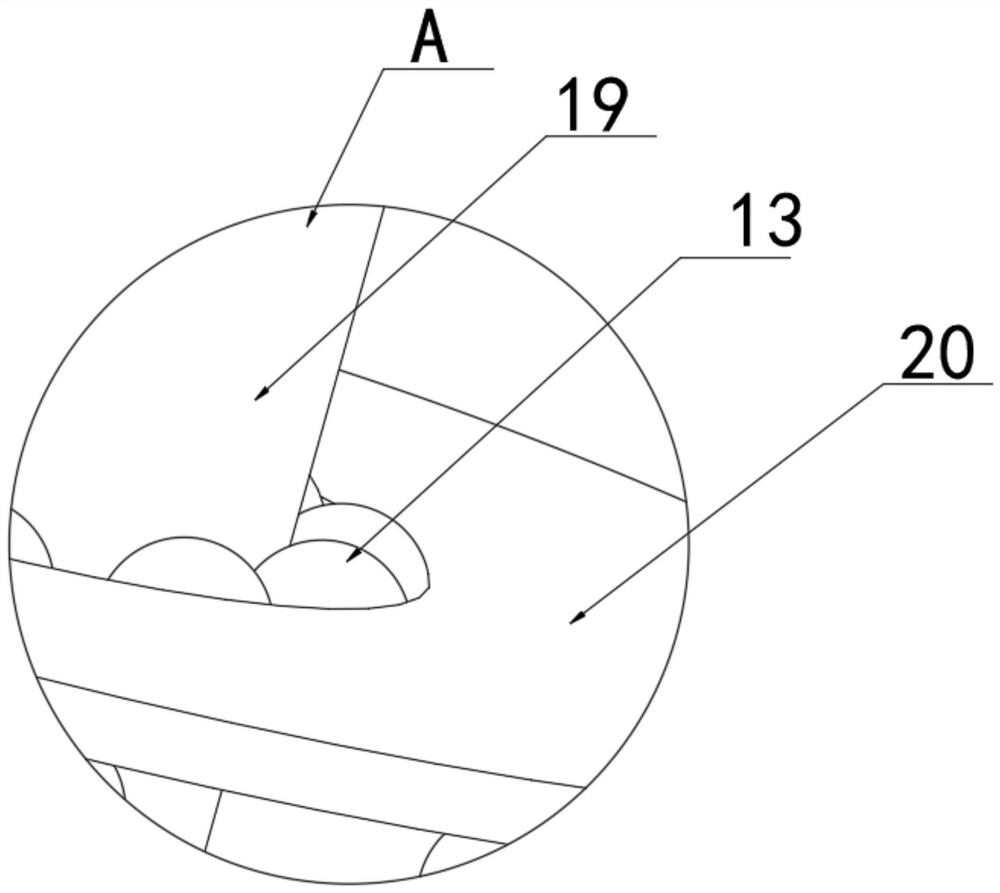

[0028] The adjustment mechanism includes a stretching cloth 15, which is made of elastic material, and a plurality of first vertical rods 21 are arranged on the outside of the stretching cloth 15, and the stretching clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com