Rapid mixing magnetic stirrer and working method thereof

A magnetic stirrer and magnetic stirring technology, applied to chemical instruments and methods, mixers, mixer accessories, etc., can solve the problems of not easy to fix the stirring container, difficult to drive the upper stirring, slow stirring speed, etc., to expand the scope of use, Effects that cost less to apply and speed up mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

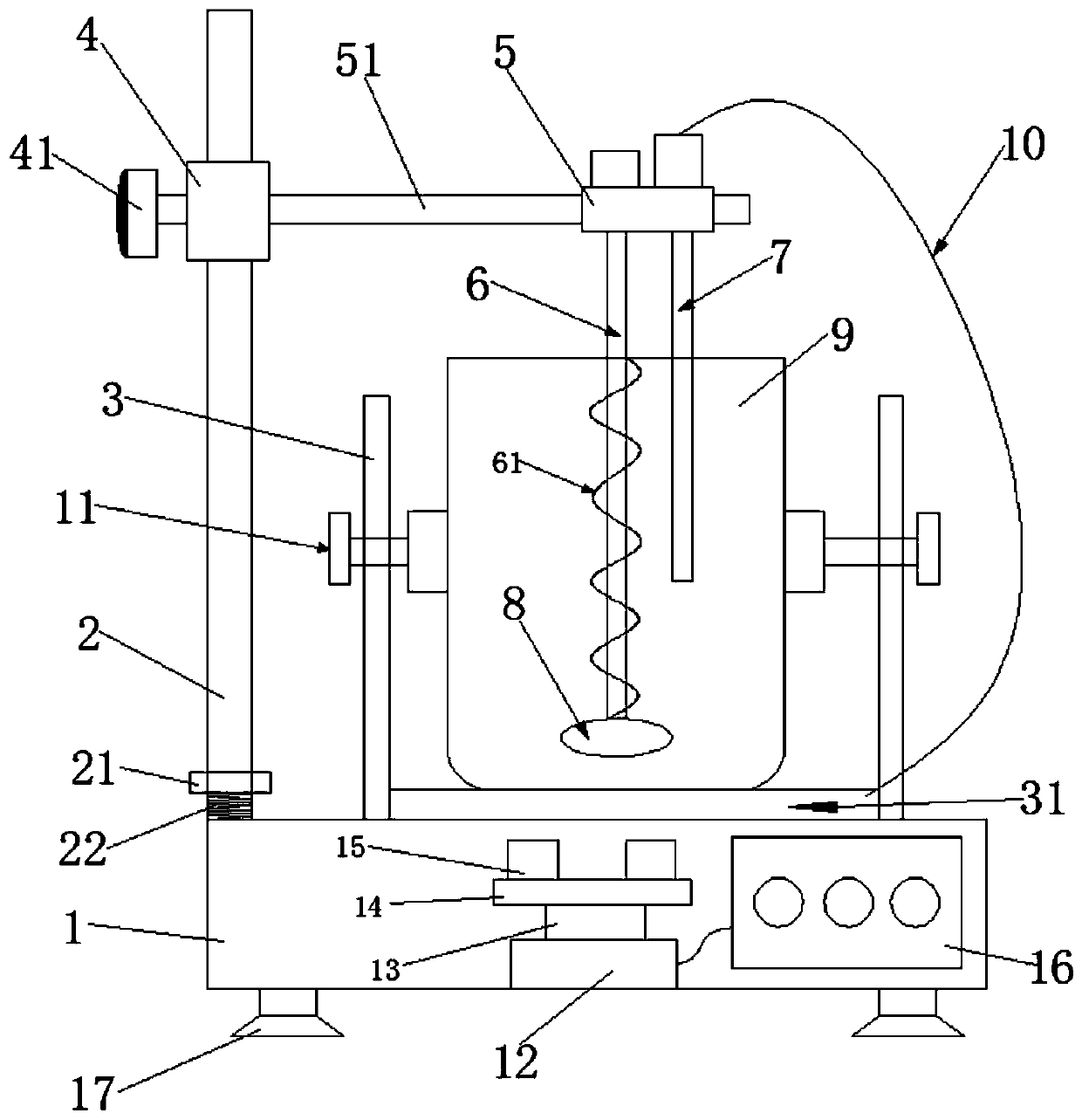

[0026] Such as figure 1 The fast-mixing magnetic stirrer shown includes a magnetic stirrer body 1. A pole 2 is provided on the upper surface of the left end of the magnetic stirrer body 1, and a first sliding seat 4 is provided on the upper end of the pole 2. A sliding seat 4 is provided with a fastening bolt 41 for fixing its position on the vertical pole, the first sliding seat 4 is sleeved with a cross bar 51, and the other end of the cross bar 51 is provided with a second sliding seat 5 , A stirring rod 6 and a temperature sensor 7 are vertically sleeved in the second sliding seat 5, a magnetic stirring bar 8 is arranged at the bottom of the stirring rod 6, and a motor 12 is arranged in the magnetic stirrer body 1. The top of 12 is connected with a supporting plate 14 through a rotating shaft 13, a high-temperature magnet 15 is fixedly installed on the supporting plate 14, and the motor 12 is connected to a control box 16 in parallel;

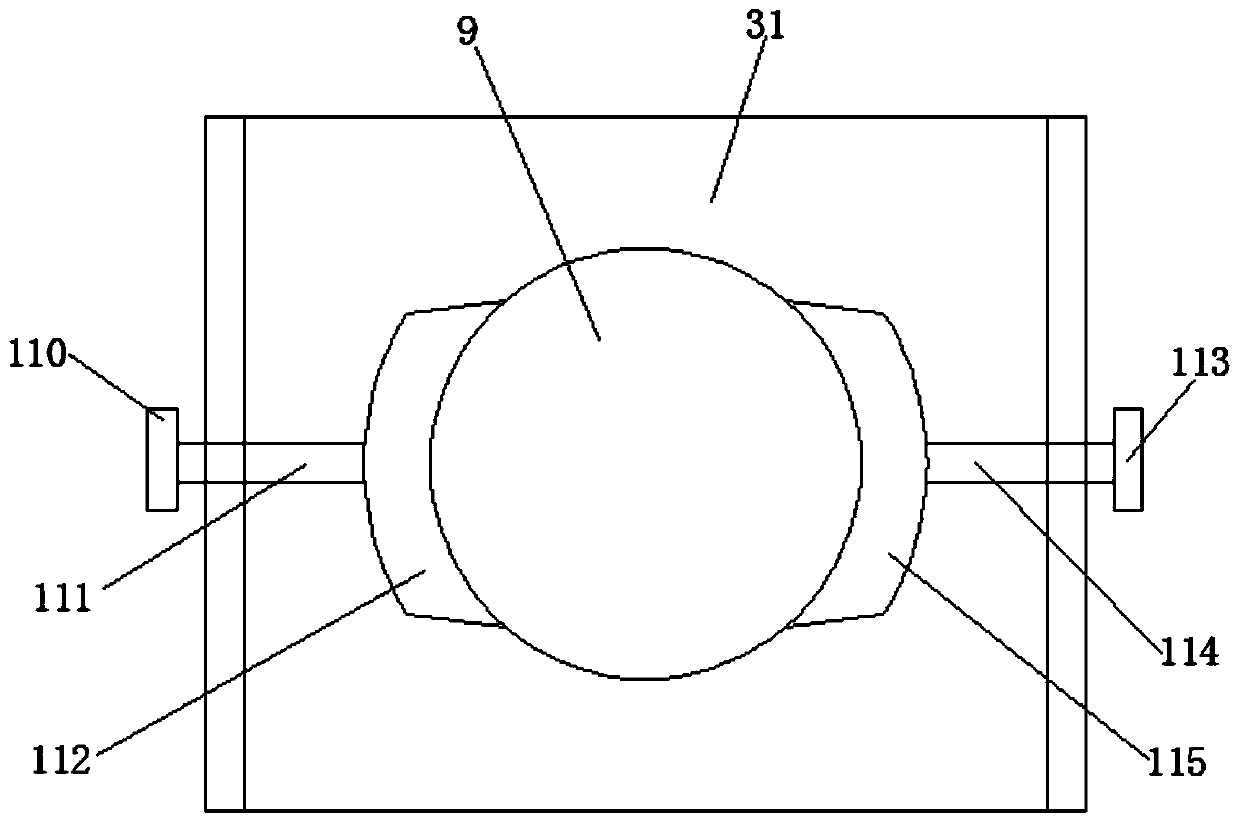

[0027] Wherein, the upper surface of th...

Embodiment 2

[0033] The magnetic stirrer body 1, the upper surface of the left end of the magnetic stirrer body 1 is provided with a vertical rod 2, the upper end of the vertical rod 2 is provided with a first sliding seat 4, and the first sliding seat 4 is provided for fixing it on The fastening bolt 41 on the upright position, the first sliding seat 4 is sleeved with a cross bar 51, the other end of the cross bar 51 is provided with a second sliding seat 5, and the second sliding seat 5 is vertically sleeved A stirring rod 6 and a temperature sensor 7 are provided, the bottom of the stirring rod 6 is provided with a magnetic stirrer 8, the magnetic stirrer body 1 is provided with a motor 12, and the top of the motor 12 is connected with a support plate 14 through a rotating shaft 13 , A high temperature magnet 15 is fixedly installed on the support plate 14, and the motor 12 is connected to the control box 16 in parallel;

[0034] Wherein, the upper surface of the magnetic stirrer body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com