Hydraulic support and tamping mechanism

A technology of hydraulic jacks and movable beams, applied in pillars/brackets, mining equipment, earthwork drilling and mining, etc., can solve problems affecting the normal operation of the tamping mechanism and reduce the working efficiency of the hydraulic support of the tamping mechanism, and achieve simple structure, good orientation and Supporting effect, reducing accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

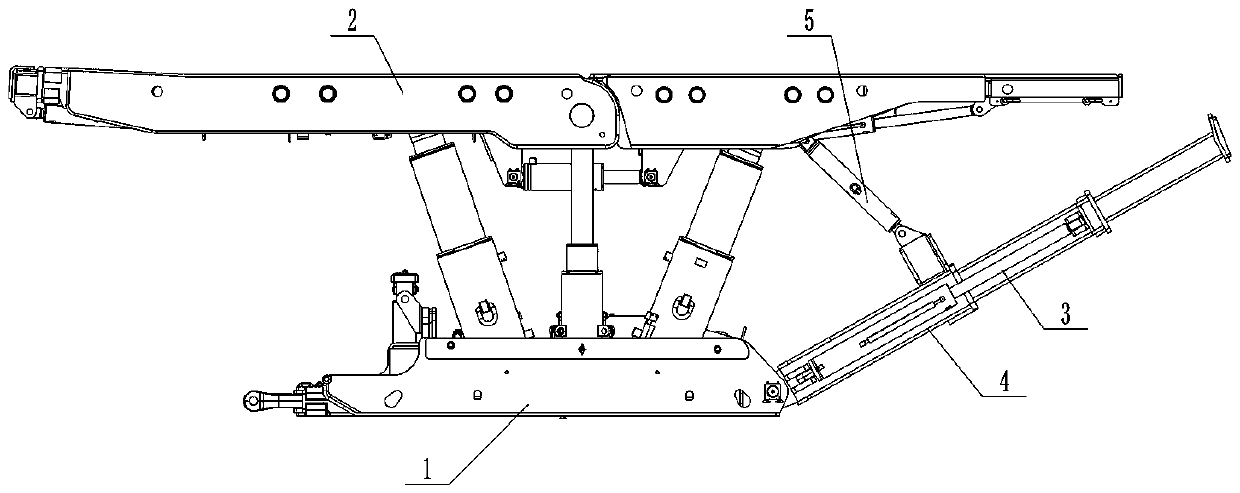

[0053] like figure 1 As shown, the hydraulic support includes a base 1, a top beam 2 is supported above the base 1, and a tamping mechanism 3 hinged on the base 1 is provided at the rear of the base 1. The tamping mechanism 3 includes a tamping beam 4, which can swing up and down. And it can also be stretched back and forth to push the material and compact the filling material within the full mining height range. In this embodiment, a swing jack 5 is hinged between the tamping beam 4 and the top beam 2 , and the tamping beam 4 can be driven to swing up and down by the swing jack 5 .

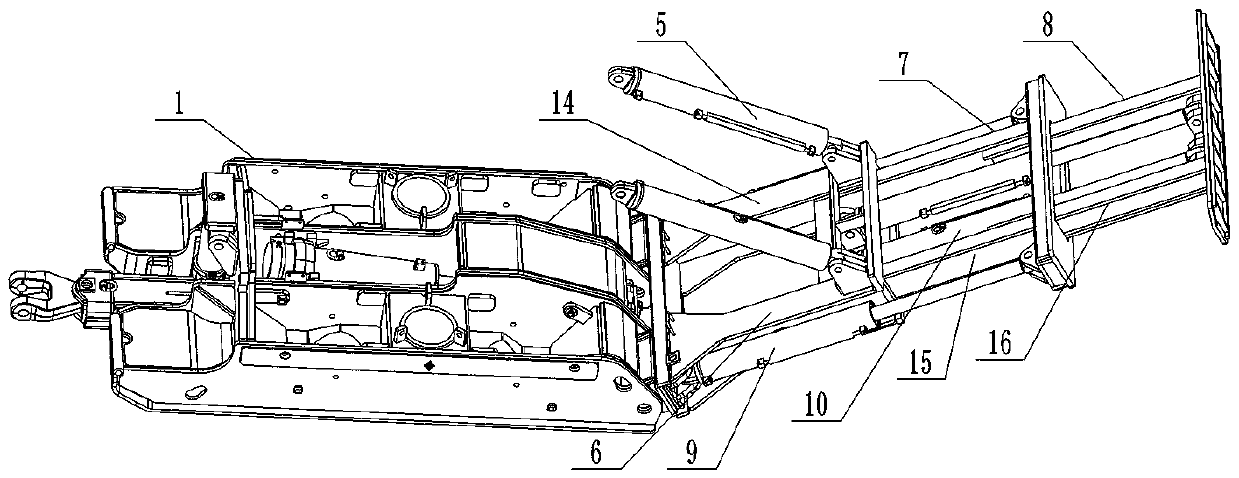

[0054] like figure 2 As shown, the tamping beam 4 includes a fixed beam section 6 and a movable beam section arranged along the length direction of the tamping beam 4, the front end of the fixed beam section 6 is hinged on the base 1, and there are two movable beam sections, which are respectively first-class movable beams Segment 7 and secondary movable beam segment 8. The first-level movabl...

specific Embodiment 2

[0066] The difference between the tamping mechanism of the hydraulic support in this embodiment and the tamping mechanism disclosed in the utility model patent document with the authorized announcement number CN201874613U is that the primary cover plate and the secondary cover plate are not set in the tamping mechanism of this embodiment, and each box The bottom plate of the body structure is a hollow structure that penetrates up and down, so that the pendulum beam, the first-level telescopic beam and the second-level telescopic beam all form a hollow structure, so that coal gangue can pass through from top to bottom and reduce accumulation in the compacting mechanism. The amount of gangue on the top improves the working efficiency of the tamping mechanism.

specific Embodiment 3

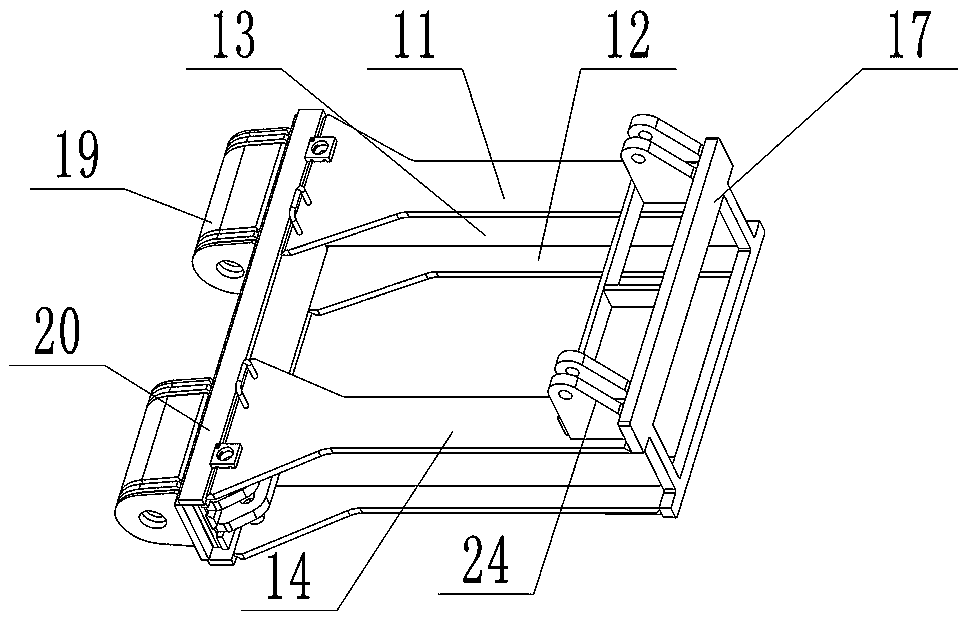

[0068] The difference from the specific embodiment 1 is that only the fixed beam section is a hollow structure formed by the frame structure, the two secondary guide columns of the first-level movable beam section are connected by connecting plates, and the two second-level guide columns of the second-level movable beam section There is also a connecting plate between the telescopic columns, and the two telescopic columns are arranged above the connecting plate between the two secondary guide columns to increase the strength of the primary movable beam section and the secondary movable beam section, and the secondary hydraulic jacks are connected Between the connecting plate and the compacting plate, and above the connecting plate of the first-level movable beam section and the connecting plate of the second-level movable beam section, so as to realize the front and rear expansion and contraction of the second-level telescopic beam section.

[0069] In other embodiments, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com