Test wire winding device

A technology of test wires and wire winders, which is applied in the field of storage of test wires for power plant maintenance, can solve the problems of easily entangled wires and damage, etc., and achieve the effects of solving the inconvenience of storage, prolonging the service life, and saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

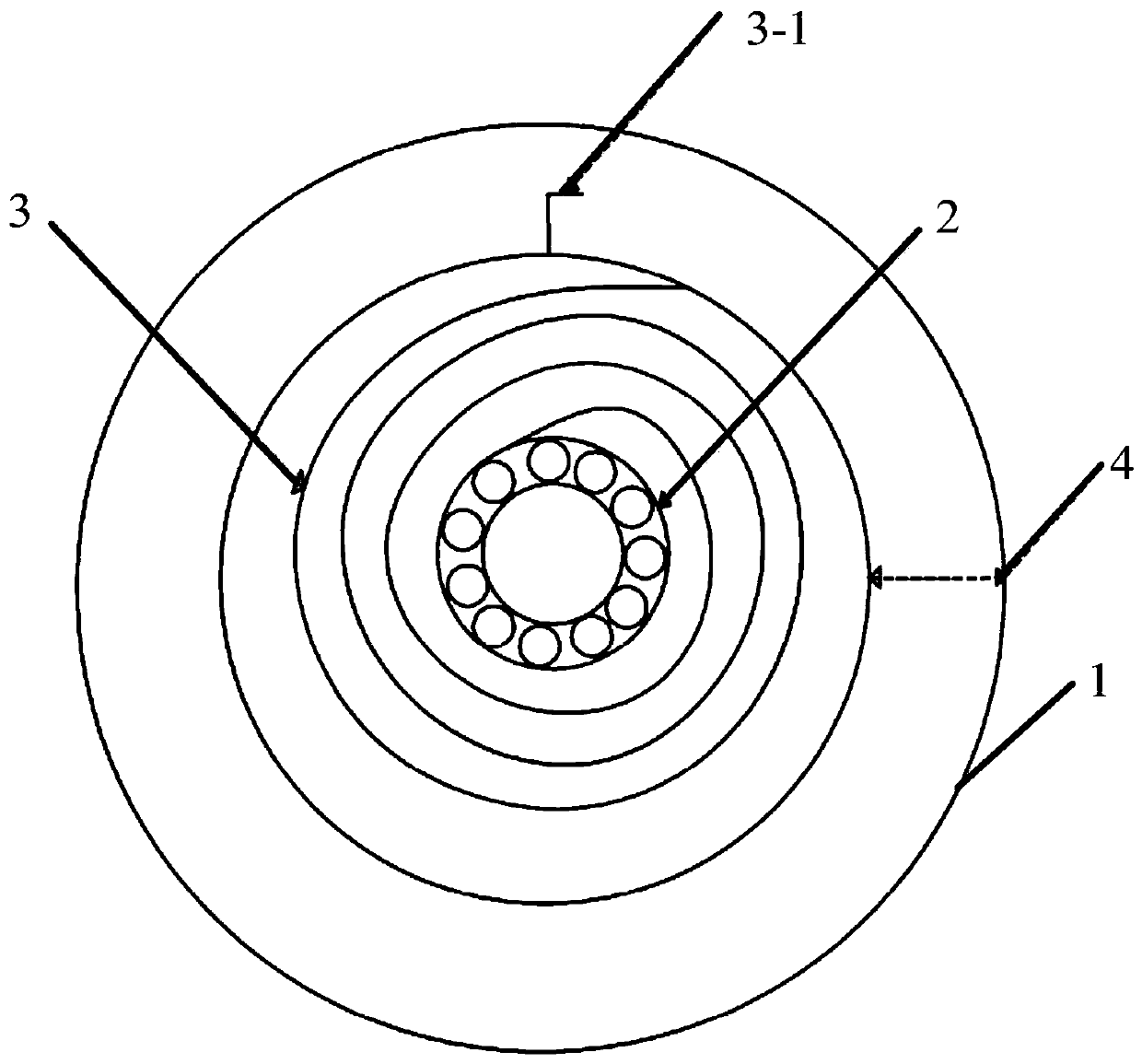

[0019] Specific implementation mode 1. Combination figure 1 As shown, the present invention provides a test wire winder, including a housing 1, a rotating shaft 2 and a plurality of take-up units,

[0020] The rotating shaft 2 is arranged inside the casing 1, and the two ends of the rotating shaft 2 are fixed at the center of the corresponding surface of the casing 1;

[0021] A plurality of take-up units are arranged axially on the rotating shaft 2, and a wire storage space 4 is formed between each take-up unit and the housing 1; each take-up unit is connected to the wire to be stored through an elastic member 3, and is 3 Provide winding preload.

[0022] In this embodiment, multiple sets of test wires can be collectively accommodated along the axial direction of the rotating shaft 2 through multiple wire take-up units, and different wires are separated from each other to avoid the occurrence of entanglement. The axial length of each take-up unit can be appropriately set ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com