Cutting equipment for processing mechanical accessories

A technology of cutting equipment and processing machinery, which is applied in the direction of metal processing machinery parts, metal processing equipment, shearing machine equipment, etc., can solve the problems of shortening the service life of the blade, bulky cutting device, inconvenient cooling of the blade, etc., to prolong the service life, Improved cooling effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

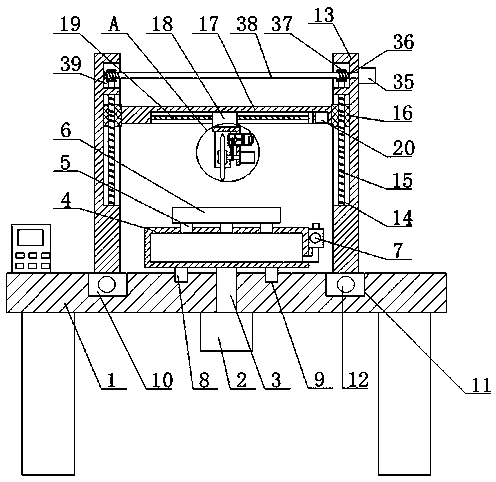

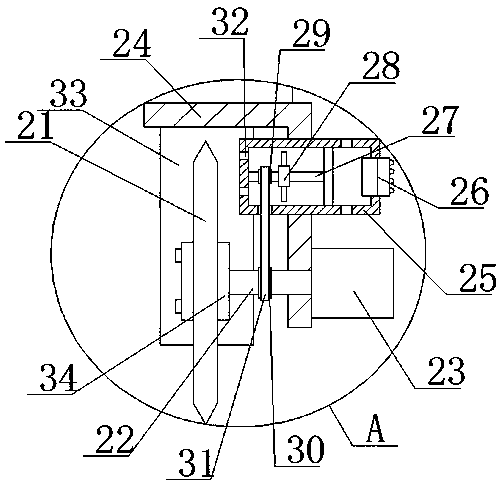

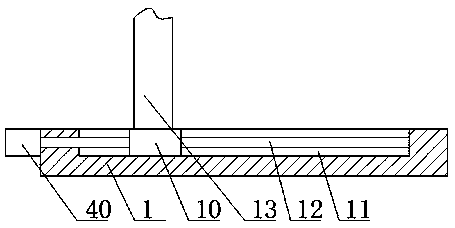

[0030] refer to Figure 1-5 , a cutting device for processing mechanical parts, including a processing plate 1, the top of the processing plate 1 is provided with two longitudinal drive mechanisms, both longitudinal drive structures are provided with vertical plates 13, between the two vertical plates 13 The same lifting plate 17 is slidably installed, the bottom of the lifting plate 17 is provided with a transverse drive structure, the transverse drive structure is connected with a fixing frame 24, the fixing frame 24 is provided with a cutting structure and a cooling structure, and the fixing frame 24 is provided with a dust blocking structure Plate 33, the top of the processing plate 1 is provided with a rotating structure, the rotating structure is connected with a placing box 4, the top of the placing box 4 is connected with a plurality of negative pressure pipes 5, and the same mechanical fitting 6 is connected to the plurality of negative pressure pipes 5 .

[0031] In...

Embodiment 2

[0041] refer to Figure 1-5 , a cutting device for processing mechanical parts, including a processing plate 1, the top of the processing plate 1 is provided with two longitudinal drive mechanisms, both longitudinal drive structures are provided with vertical plates 13, between the two vertical plates 13 The same lifting plate 17 is slidably installed, the bottom of the lifting plate 17 is provided with a transverse drive structure, the transverse drive structure is connected with a fixing frame 24, the fixing frame 24 is provided with a cutting structure and a cooling structure, and the fixing frame 24 is provided with a dust blocking structure Plate 33, the top of the processing plate 1 is provided with a rotating structure, the rotating structure is connected with a placing box 4, the top of the placing box 4 is connected with a plurality of negative pressure pipes 5, and the same mechanical fitting 6 is connected to the plurality of negative pressure pipes 5 .

[0042] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com