Continuous hydrogenation method and application of ethyl pyrazine-2-carboxylate

A technology of ethyl formate and pyrazine, which is applied in the field of continuous hydrogenation of ethyl pyrazine-2-carboxylate, can solve problems such as difficulty in controlling spontaneous combustion of catalysts, heavy labor in autoclave operation, and inability to control excessive reduction, etc. Risk of spontaneous combustion, reduced risk of impurity formation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Dispersion process: disperse ethyl pyrazine-4-carboxylate and hydrogen in collision convection (jet method), the gas-liquid ratio is 1:100, and form a gas-liquid mixture containing small droplets with a particle size of 50nm to 50μm , as the reaction raw material.

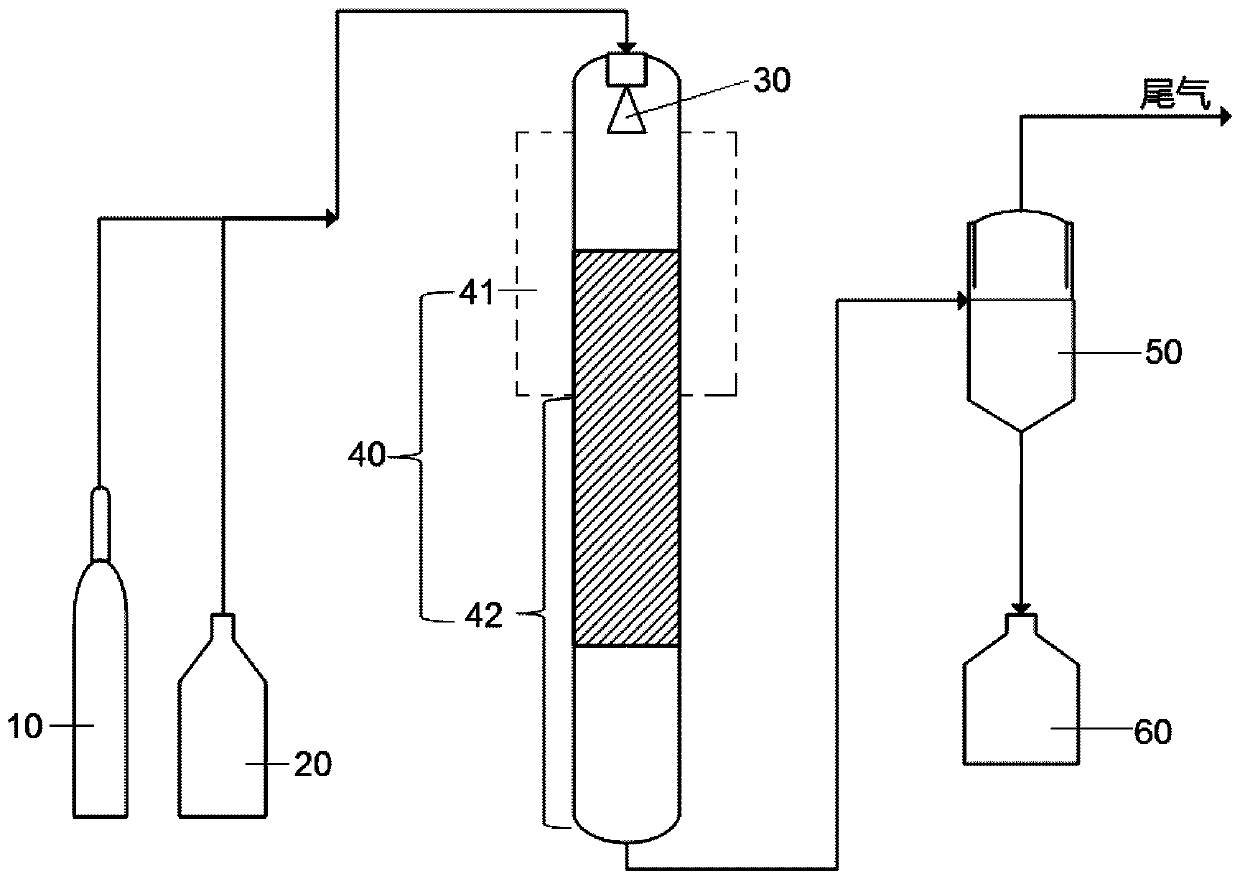

[0042] Continuous reaction: Pack 5% Ru / C catalyst in the reaction column. Alumina microspheres (1mm) are used at both ends, the mass of the middle catalyst is 28.38g, the filling height is 300mm, the filling diameter is 19.2mm, and the particle size of the catalyst is 1mm. It is used as the catalytic hydrogenation device 40 (fixed bed reactor).

[0043] The above-mentioned reaction raw materials are continuously passed into the above-mentioned catalytic hydrogenation device 40 (fixed-bed reactor) for catalytic hydrogenation reaction to obtain ethyl piperazine-4-carboxylate, wherein the catalytic hydrogenation device 40 (fixed-bed reactor) is controlled in two stages. temperature, and along the material flow...

Embodiment 2

[0045] Dispersion process: disperse ethyl pyrazine-4-carboxylate and hydrogen in collision convection (jet method), the gas-liquid ratio is 1:100, and form a gas-liquid mixture containing small droplets with a particle size of 50nm to 50μm , as the reaction raw material.

[0046] Continuous reaction: Pack 5% Ru / C catalyst in the reaction column. Alumina microspheres (1mm) are used at both ends, the mass of the middle catalyst is 28.38g, the filling height is 300mm, the filling diameter is 19.2mm, and the particle size of the catalyst is 1mm. It is used as the catalytic hydrogenation device 40 (fixed bed reactor).

[0047] The above-mentioned reaction raw materials are continuously passed into the above-mentioned catalytic hydrogenation device 40 (fixed-bed reactor) for catalytic hydrogenation reaction to obtain ethyl piperazine-4-carboxylate, wherein the catalytic hydrogenation device 40 (fixed-bed reactor) is controlled in two stages. temperature, and along the material flow...

Embodiment 3

[0049] Dispersion process: Disperse ethyl pyrazine-4-carboxylate and hydrogen gas by means of collision convection (jet flow method), with a gas-liquid ratio of 1:100, to form a gas-liquid mixture containing small droplets with a particle size of 50nm to 50μm. as a reaction material.

[0050] Continuous reaction: Pack 5% Ru / C catalyst in the reaction column. Alumina microspheres (1mm) are used at both ends, the mass of the middle catalyst is 28.38g, the filling height is 300mm, the filling diameter is 19.2mm, and the particle size of the catalyst is 1mm. It is used as the catalytic hydrogenation device 40 (fixed bed reactor).

[0051] The above-mentioned reaction raw materials are continuously passed into the above-mentioned catalytic hydrogenation device 40 (fixed-bed reactor) for catalytic hydrogenation reaction to obtain ethyl piperazine-4-carboxylate, wherein the catalytic hydrogenation device 40 (fixed-bed reactor) is controlled in two stages. temperature, and along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com