Robot material frame grabbing planning and collision detection method

A collision detection and robot technology, applied in the field of robotics, can solve problems such as cumbersome grasping methods for material frames, and achieve the effect of reducing model making and importing and quickly grasping results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

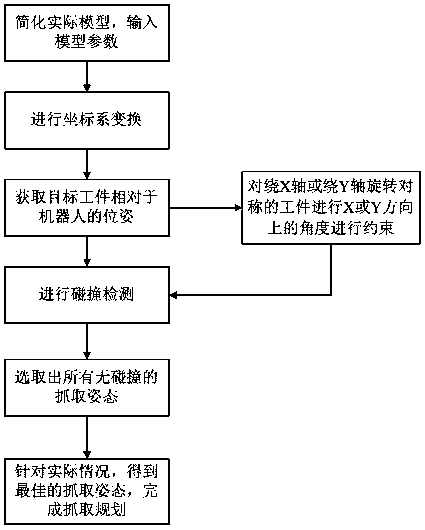

[0074] Such as figure 1 As shown, a robot material frame grasping planning and collision detection method includes the following steps:

[0075] S1: Simplify the actual model, input model parameters to establish a simplified model;

[0076] S2: Establish a coordinate system according to the simplified model, and perform coordinate system transformation;

[0077] S3: Obtain the pose of the target workpiece relative to the robot;

[0078] S4: After the pose is transformed, the grasping pose is obtained, and brought into the coordinate system for collision detection;

[0079] S5: Make grasping planning based on collision detection.

[0080] In the implementation process, by abstracting and simplifying the complex environment, establishing a simplified model, and performing collision detection and grasping planning through coordinate system transformation, the cumbersome model making and importing can be reduced, and the grasping results can be quickly given.

[0081] More spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com