An easy-to-weld ultra-high-strength and high-toughness steel and its preparation method

An ultra-high-strength, easy-to-weld technology, applied in the field of metallurgical materials and their preparation, can solve problems such as easy transformation into ferrite, and achieve the effects of low quenching temperature, good economic benefits, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail in conjunction with specific embodiments.

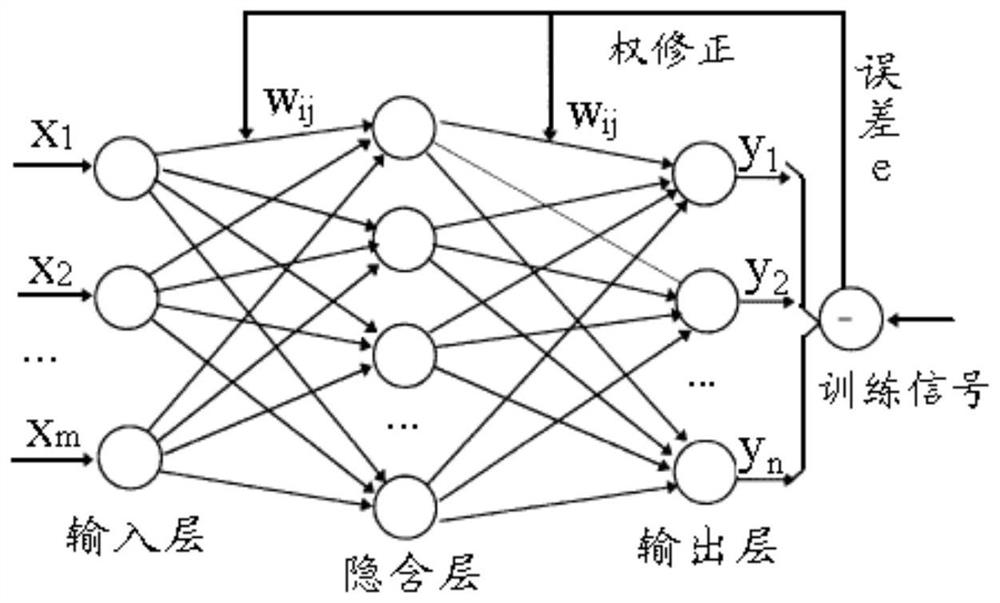

[0055] The BP network of the present invention adopts a structural model of 6×8×8×4, the training function uses trainscg, the learning rate is set to 0.1, the momentum phase factor is 0.9, and the target error value is 0.01. The number of nodes in the input layer is 6, and the content of C, Si, Mn, Mo, Cr, and V elements are used as input parameters; the number of nodes in the output layer is 4, and the output parameters are impact toughness, yield strength, tensile strength, and elongation; There are 2 hidden layers with 8 and 8 neurons respectively.

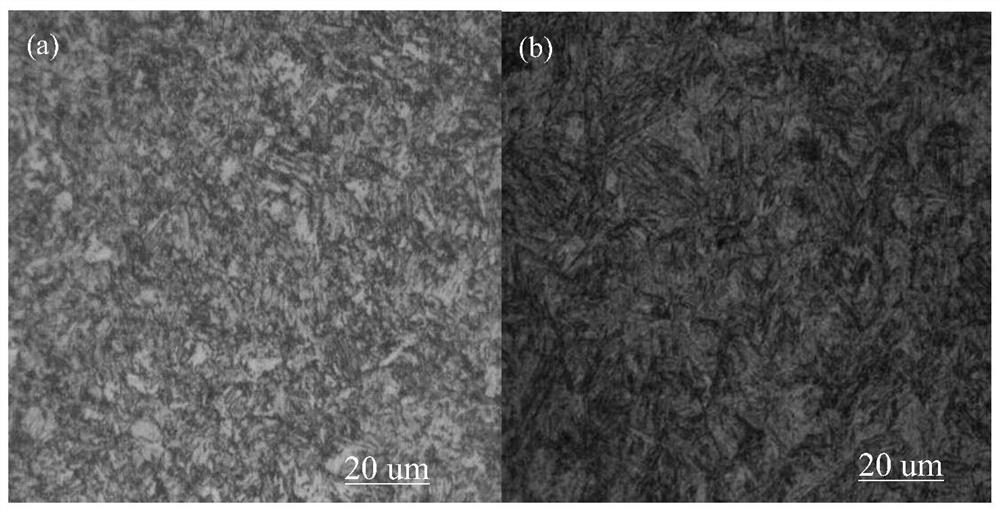

[0056] Figure 4 with Figure 5 The rule of influence of C content on strength, yield ratio, impact energy and elongation is analyzed for BP neural network. It can be seen that with the increase of C content, the yie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com