Clean pipe sealing ring automatic filling device

An automatic filling and tube sealing technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of only women with slender fingers, worn fingers of operators, occupation of labor and other problems, to solve personal injury, location Accurate and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

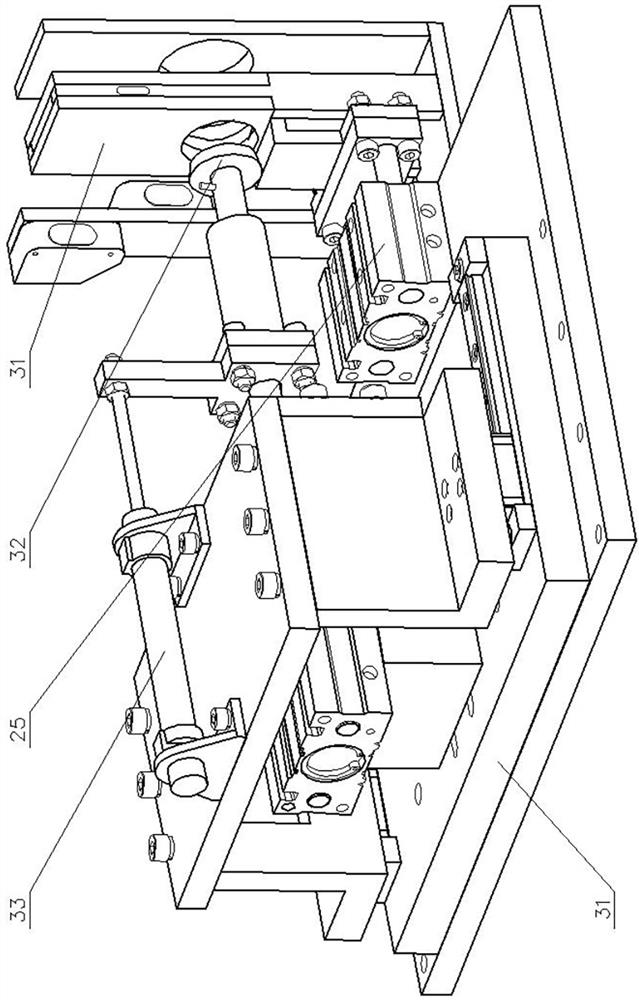

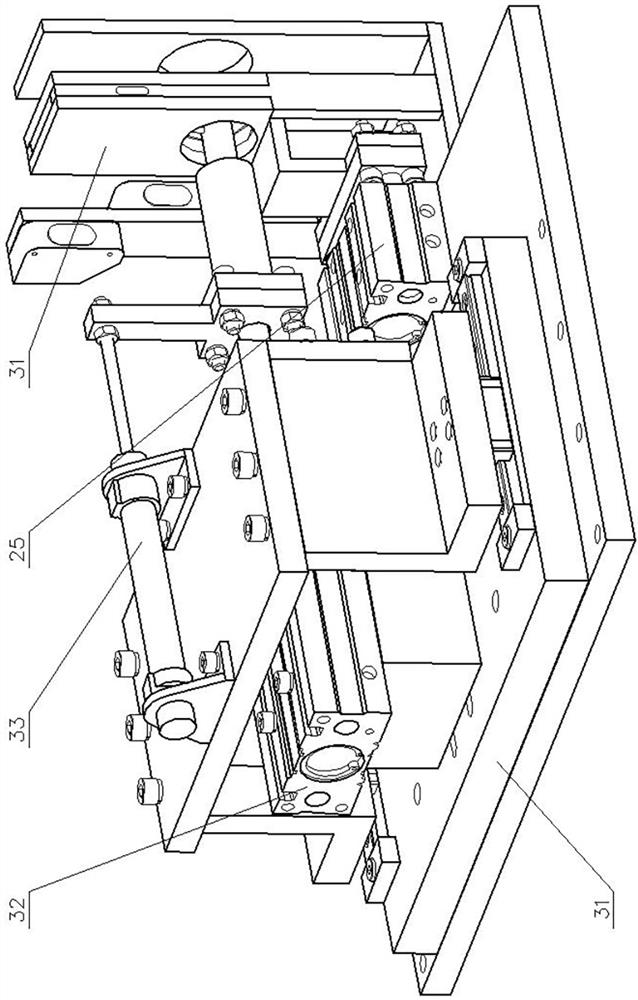

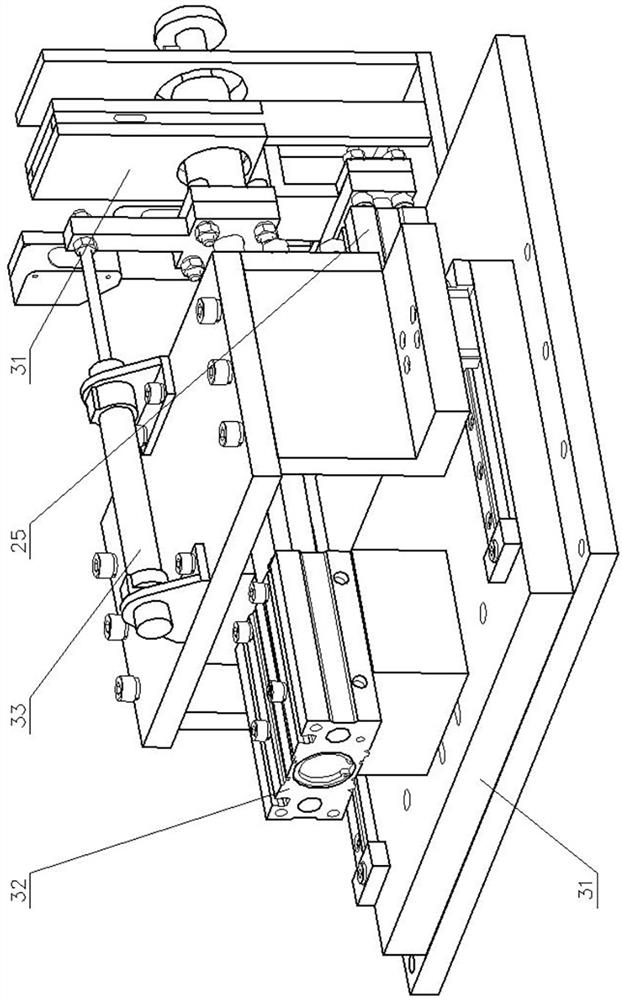

[0022] 31. Loading frame 311, backing plate 312, linear guide rail 313, propulsion cylinder seat 314, stop cylinder seat 315, transmission plate 316, socket seat plate 317, clean pipe socket 32, propulsion cylinder 321, propulsion cylinder block 322, propulsion rod 323, guide head 324, hook 33, stop cylinder 331, stop cylinder body 332, stop rod 333, crank arm 334, stop sleeve 211, partition 212, vertical channel 214, photoelectric switch 25, bracket cylinder 251, bracket cylinder block 252, bracket rod 253, supporting plate.

[0023] exist Figure 1-Figure 8 In the shown embodiment: the partition 211 of the loading frame 31 of the clean pipe sealing ring automatic filling device is in the shape of a rectangular flat plate, and a short side of the upper plane of the horizontally arranged partition 211 is equipped with a backing plate in the shape of a rectangular flat plate 311, and the long side of the backing plate 311 is aligned with the short side of the partition plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com