Assembled battery box and assembling method thereof

An assembled battery technology, which is applied in the manufacture of battery components, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve problems such as short circuits, and achieve the effects of ensuring sealing, ensuring safety, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

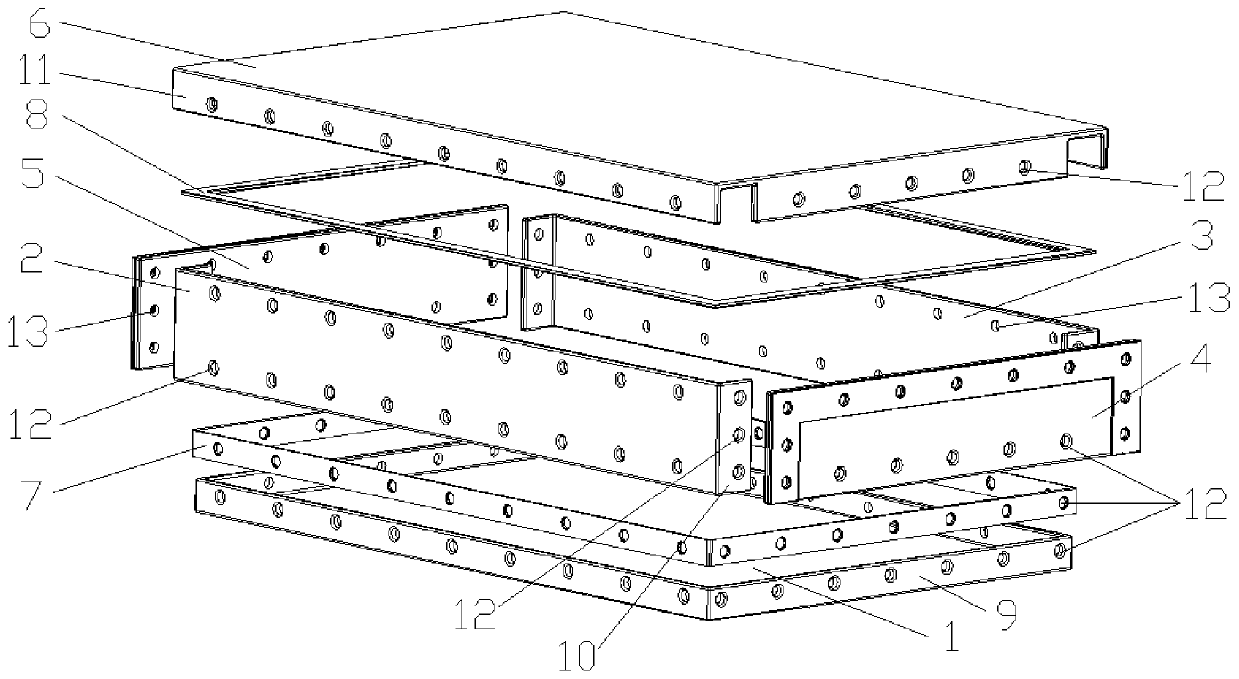

[0042] This embodiment provides an assembled battery box, whose structure is detailed in the attached Figure 1-4 Shown: including bottom plate 1, side plate, top plate 6, first sealing ring 7 and second sealing ring 8, said side plate includes left side plate 2, right side plate 3, and the positive and negative poles close to the module The front side plate 4 and the rear side plate 5; the first sealing ring 7 is arranged between the bottom plate 1 and the side plate, and the second sealing ring 8 is arranged between the side plate and the top plate 6; The left side plate 2 and the right side plate 3 are fixed by bolts, the bottom plate 1 is respectively fixed with the front side plate 4 and the rear side plate 5 by bolts, and the top plate 6 is respectively connected with the left side plate 2, the right side plate 3, the front side The plate 4 and the rear side plate 5 are fixed by bolts, and the two sides of the left side plate 2 and the right side plate 3 are respectively...

Embodiment 2

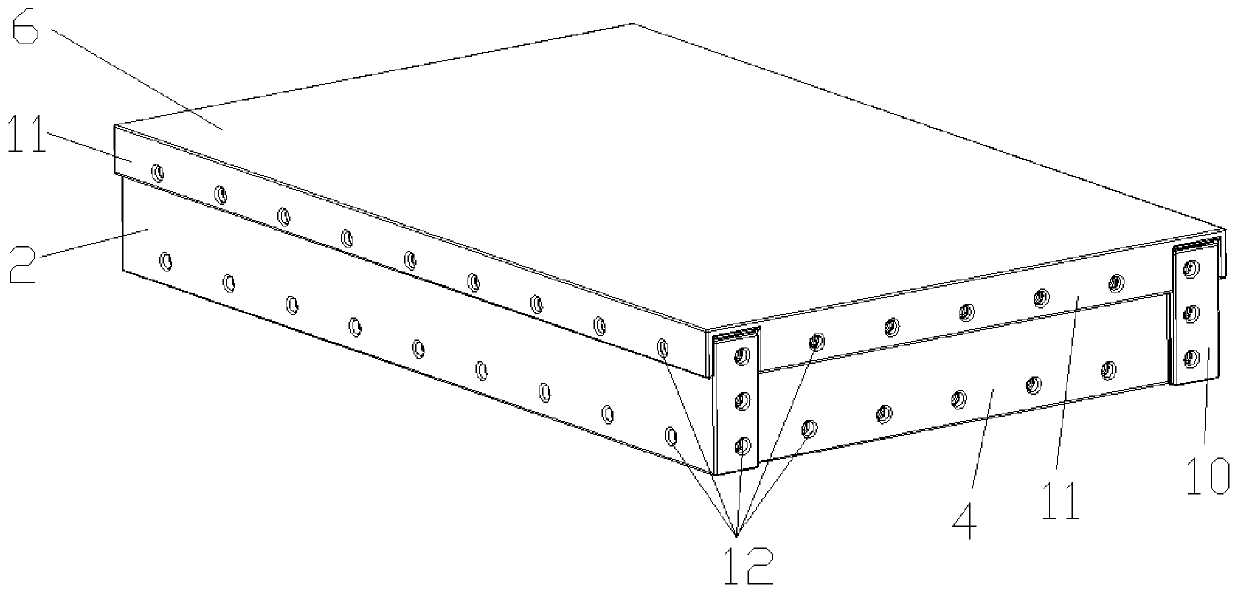

[0050] This embodiment provides an assembled battery box, whose structure is detailed in the attached Figure 5-7 Shown: including bottom plate 1, side plate, top plate 6, first sealing ring 7 and second sealing ring 8, said side plate includes left side plate 2, right side plate 3, and the positive and negative poles close to the module The front side plate 4 and the rear side plate 5; the first sealing ring 7 is arranged between the bottom plate 1 and the side plate, and the second sealing ring 8 is arranged between the side plate and the top plate 6; The left side plate 2 and the right side plate 3 are fixed by bolts, the bottom plate 1 is respectively fixed with the front side plate 4 and the rear side plate 5 by bolts, and the top plate 6 is respectively connected with the left side plate 2, the right side plate 3, the front side The plate 4 and the rear side plate 5 are fixed by bolts, and the two sides of the left side plate 2 and the right side plate 3 are respectively...

Embodiment 3

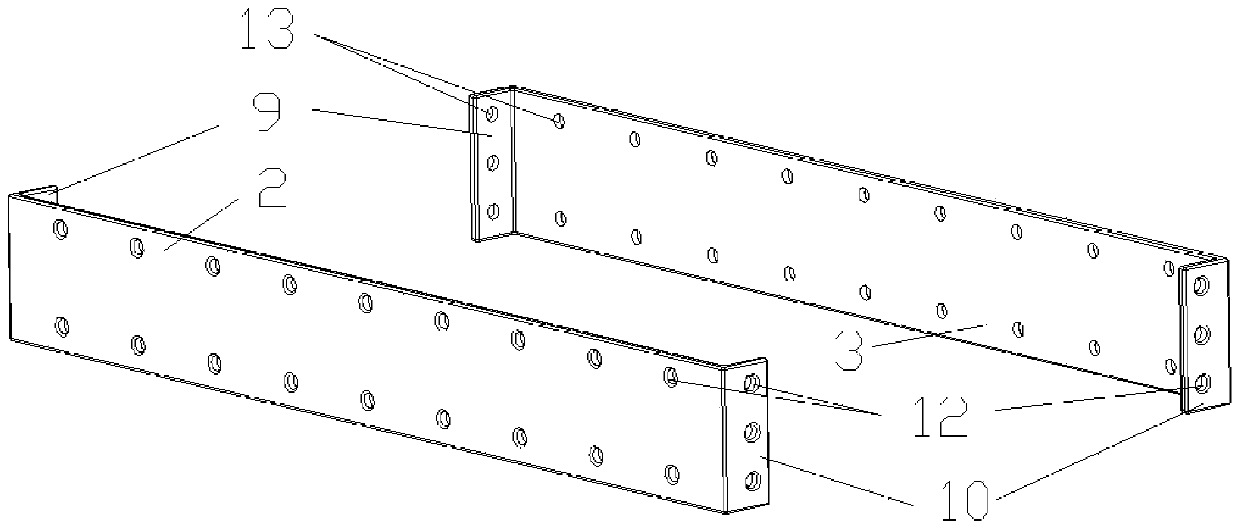

[0058] This embodiment provides an assembled battery box, whose structure is detailed in the attached image 3 and 8 Shown: including bottom plate 1, side plate, top plate 6, first sealing ring 7 and second sealing ring 8, said side plate includes left side plate 2, right side plate 3, and the positive and negative poles close to the module The front side plate 4 and the rear side plate 5; the first sealing ring 7 is arranged between the bottom plate 1 and the side plate, and the second sealing ring 8 is arranged between the side plate and the top plate 6; The left side plate 2 and the right side plate 3 are fixed by bolts, the bottom plate 1 is respectively fixed with the front side plate 4 and the rear side plate 5 by welding, and the top plate 6 is respectively connected with the left side plate 2, the right side plate 3, the front The side plate 4 and the rear side plate 5 are fixed by bolts, and the two sides of the left side plate 2 and the right side plate 3 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com