Non-return body assembly applied to electromagnetic pump and anti-blocking electromagnetic pump

An electromagnetic pump and non-return technology, applied in the field of electromagnetic pumps, can solve the problems of high production and maintenance costs, complex non-return structure, etc., and achieve the effect of simple and reliable overall structure and reduced production and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

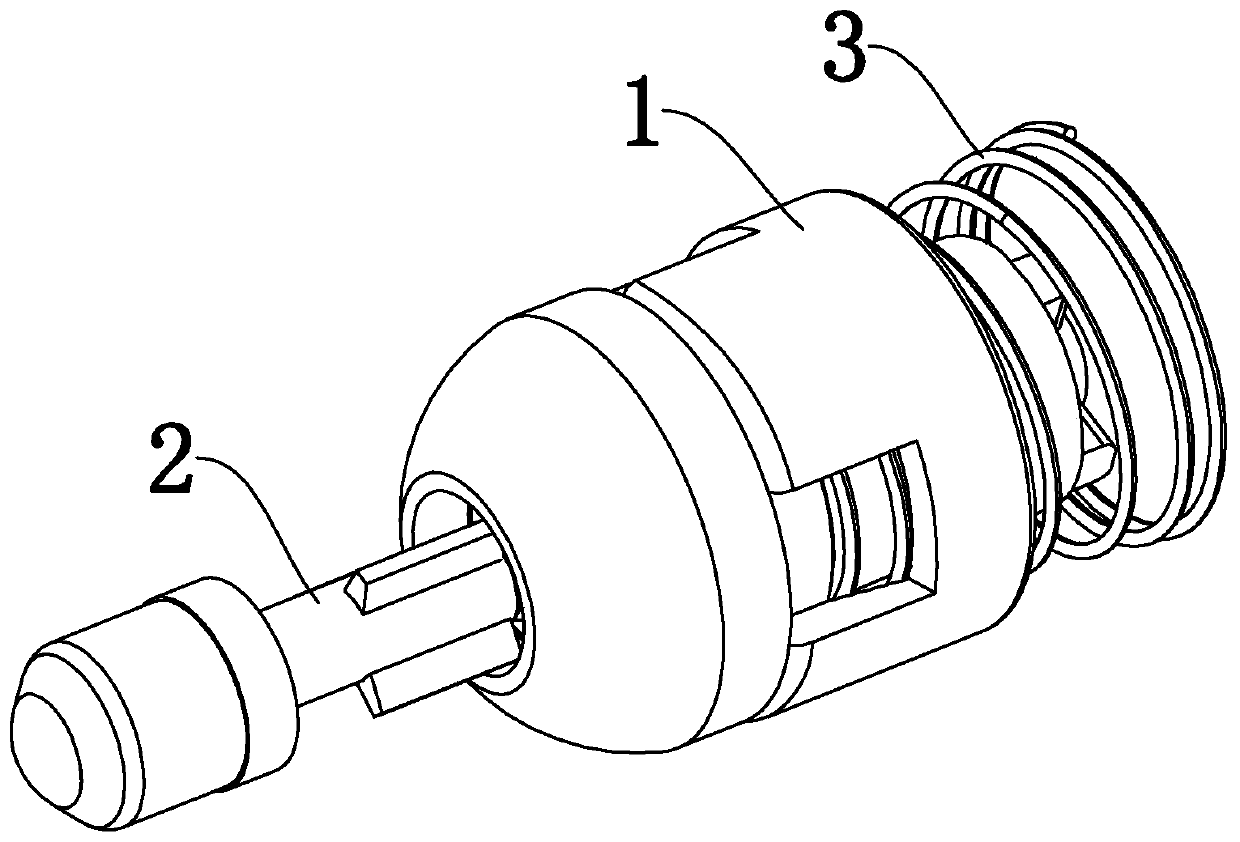

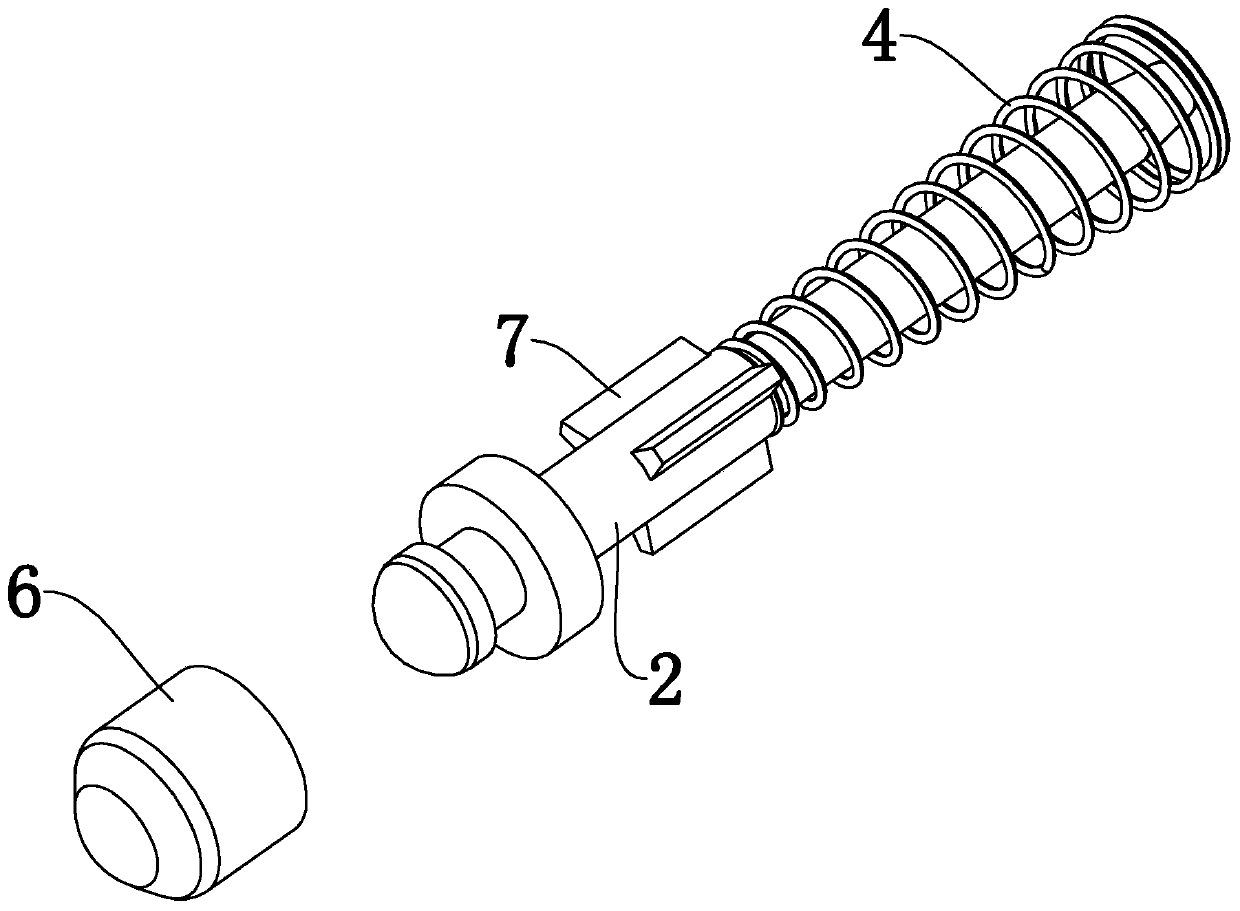

[0035] refer to Figure 1 to Figure 3 As shown in , the non-return body assembly provided by this embodiment is applied in the electromagnetic pump. The electromagnetic pump is composed of a working chamber and a liquid outlet chamber arranged in front and back, and a liquid flow hole connecting the two, and the working chamber is movable. The pump core 12; the non-return body assembly includes:

[0036] The first non-return body 1 can be accommodated axially in the liquid outlet cavity and has a first sealing body 5 at the front end. The first non-return body 1 is also provided with a mounting hole penetrating to the front end surface;

[0037] The first spring 3 is arranged in the liquid outlet chamber to urge the first non-return body 1 to reset, and the first non-return body 1 closes the rear opening of the liquid flow hole;

[0038] The non-return member, the front end and the pump core 12 form a valve that allows the water flow to pass through in one direction from fron...

Embodiment 2

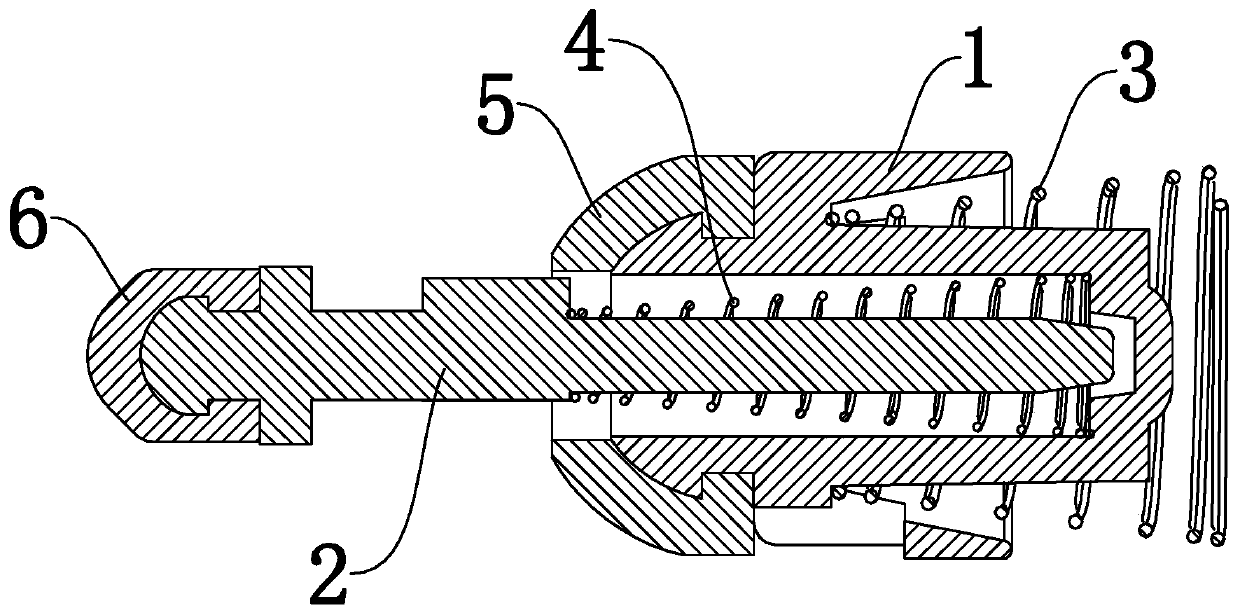

[0048] refer to Figure 4 to Figure 6 As shown in , the anti-blocking electromagnetic pump provided by this embodiment includes a main body, wherein the main body is also provided with a non-return body assembly as described in the first embodiment above, so that the non-return body assembly and the pump core seat can be solved conveniently and reliably. The problem of adhesion between 15 and the problem of dirt blocking the liquid flow hole, and the overall structure is simple and reliable, and the production and maintenance costs are greatly reduced.

[0049] In a preferred embodiment, specifically as Figure 5 and Figure 6 As shown in , the main body includes a metal tube 8, a coil 9 sheathed on the outer circumference of the metal tube 8, a coil overmolding 16 covering the outer circumference of the coil 9, a magnetic conductor 10 arranged outside the coil overmolding 16, and a magnetic conductor 10 arranged on the outer circumference of the coil 9. The pump casing 14 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com